A STATE I SYSTEM IN THE JKTNG

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

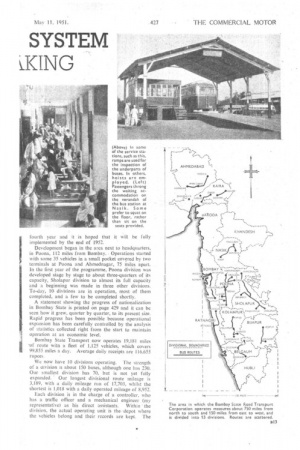

In Three Years the Bombay State Undertaking has been Highly Developed, and Now Operates 1,125 Vehicles in 10 Divisions. Three More Divisions are to be Opened

By Major H. Waimsley, THE State of Bombay covers an area of 76,400 square miles. It is 750. miles long and its average width is 127 miles. In 1948, the tiovernment decided to nation alize raral road passenger transport services, but the scheme implemented in June of that year excluded areas under the „egis of the Indian States, covering only Bombay Province, The Province was split into a number

of divisions, but the country as then constituted imposed limitations upon the formation of ideal operational units.

After the attainment of Indian independence, the Indian States joined Bombay and for the purpose of

transport the area was realigned into I3-divisions. The boundaries of these divisions were worked out on a basis of homogeneity of traffic flow and viability in traffic operation. Each was formed to be able to operate between 150 and 250 vehicles for rural passenger services* only.

Nationalization meant starting from scratch. Existing

units in the country were widely distributed and there were hardly any reasonably established undertakings.

Most operators had but a few vehicles and many were owner-drivers. The organization of a large-scale system therefore involved elaborate planning and the setting-up of a comprehensive administration.

Another difficulty lay in the shortage of vehicles. Most of the private operators' vehicles could not be

taken over, because they were old and in bad condition. The organization had to start with a new fleet. A

further problem arose from the physical layout of the State—a long strip along the coast—and the great distance from central to divisional headquarters was -a matter to be reckoned with Under the original scheme for Bombay Province, ,arovision was made for a total fleet of 2,000 vehicles. nI2 When the former princely States were absorbed, the nationalization scheme was revised and a new estimate made for a fleet of 2,500.

The original scheme was worked out for completion in three years, but because of the increase in the size of the operation, and the difficulty in obtaining vehicles, equipment and technical personnel, it will not be implemented in this time. On June I, 1951, the date set for completion, there will be three divisions still to be taken over and the expansion of a few more to be effected. The scheme will have to be extended to a

fourth year and it is hoped that it will be fully implemented by the end of 1952.

Development began in the area next to headquarters, in Poona, 112 miles from Bombay.. Operations started with some 35 vehicles in a small pocket covered by two terminals at Poona and Ahmednagar, 75 miles apart. In the first year of the programme, Poona division was developed stage by stage to about three-quarters of its capacity, Sholapur division to almost its full capacity and a beginning was made in three other divisions. To-day, 10 divisions are in operation, most of them completed, and a few to be completed shortly.

A statement showing the progress of nationalization in Bombay State is printed on page 429 and it can be seen how it grew, quarter by quarter, to its present size. Rapid progress has been possible because operational expansion has been carefully controlled by the analysis of statistics collected right from the start to maintain operation at an economic level.

Bombay State Transport now operates 19,181 miles 'of route witt a fleet of 1,125 vehicles, which covers 99,855 miles a day. Average daily receipts are 116,655 rupees.

We now have 10 divisions operating. The strength of a division is about 150 buses, although one has 230. Our smallest division has 70, but is not yet fully expanded. Our longest divisional route mileage is 3,189, with a daily mileage run of 17,703, whilst the shortest is 1,018 with a daily operated mileage of 8,952.

Each division is in the charge of a controller, who has a traffic officer and a mechanical engineer (my representative) as his direct assistants. Within the division, the actual operating unit is the depot where the vehicles belong and their records are kept. The depot manager is required to be a mechanical officer first, a traffic officer second and an administrator third. To assist him he has a traffic officer and a foreman or a head mechanic, depending on the size of the depot.

In compiling the operating schedules, every effort is made to bring as many vehicles as possible back to the depots each night, but some have to stay out at terminals. • There are also some places from which small numbers of buses operate services which do not run towards the • depot. These places are known as garages.

At the divisional headquarters; in addition to its depot, there is a divisional workshop under the charge of a superintendent. In order to describe the functions of these three maintenance and repair units of the division--garage, depot and divisional workshop—it will he necessary for me to explain the policy of maintenance and repair to meet the needs of our particular operating conditions.

Initial Problems The problems with which I was faced when having to decide the policy were many. The first was presented by the atrocious road conditions. There were long lines of communication between .various centres. For various reasons, I was unable to standardize upon a small number of chassis types, and there was an absence of workshops and a dearth of engineer officers and skilled artisans.

There are two schools of thought on preventivemaintenance periods; one upholds a mileage basis and the other a time basis. I chose a time basis, because it permits an advance programme to be drawn up. However, in deciding on the periods of time, mileage was a critical factor.

Our buses cover an average of 120 miles daily, BM miles weekly, 3,000 miles monthly and 9.000 miles quarterly. With these mileages in mind, I fixed a policy of a 100-mile check to be performed daily, a 1,000-mile check weekly (with engine oil changed fortnightly), a 5.000-mile check monthly and a 10,000mile check quarterly, when chassis lubricants, are changed.

The three functions that are performed on mileage are: First, a top overhaul of the engine at 20,000 miles, then a heavy engine overhaul at 50,000 miles, and thirdly, a major (lock of the vehicle at 90,000 miles. Of these functions, all except the last two are done within the division. All equipment for overhaul and docking is housed in a central overhauling workshop situated at Poona, in the most central position of the State.

Asia's Largest Repair Shop This workshop, when completed, will be the largest motor repair workshop in Asia and will have a capacity for a daily turn-out of two vehicles, five engines and * other major chassis assemblies, eight injection pumps, 10 rebuilt batteries and 10 retreaded tyres.

Regarding repairs to components, I have issued a schedule of permissive repairs pertaining to each repair unit, my system being that minor assemblies are replaced at the depots and sent to the divisional workshops for retrieving. Major assemblies, including injection pumps, are replaced at the divisional workshop and are sent to the central overhauling workshop for overhaul. On reaching 90,0eta miles, the vehicle is sent to the central overhauling workshops where it is completely stripped and rebuilt.

Maintenance and repair functions are divided among garages, depots, divisional workshops and the central overhauling workshops according to the following schedule:—Garage: daily body wash and inspection. Depot: daily body wash and inspection; weekly chassis wash and inspection; weekly lubrication; replacement of minor assemblies; light running repairs. Divisional workshop: monthly and quarterly inspections; overhaul of minor assemblies; engine top overhauls; replftement of major assemblies; heavy running repairs; body repairs. Central overhauling workshop; vehicle docking; overhaul of major assemblies, including injection pumps; tyre retreading and major vulcanizing; battery rebuilding.

. The periodical inspections are performed against report forms which detail jobs to be done and serve as records of work carried out.

We are operating five makes of petrol-engined and six makes of oil-engined vehicles. A degree of standardization has been achieved, however;•by keeping not more than two makes, one petrol and one oil, in the bus fleets. of each of the different divisions When we first started operating. local coachbuilders made composite bodies for us and we effected a gradual improvement in specifications as we progressed. At the same time, deciding that the composite body was not the ideal for our conditions, we obtained sets of prefabricated all-metal bodies from Metal Sections, Ltd., Birmingham, and began our own coachworks in Bombay. This coachworks will be moved to the central overhauling workshop when the wing now being constructed for its accommodation is completed.

At first, we merely assembled the prefabricated parts and made 225 bodies. The next stage was to order prefabricated sets, such as pillars and longitudinals in straight lengths, roof bends and front and rear ends. Following this method, we are now progressing with 100 bodies. Our next step will be to receive only straight lengths of all the materials and to do the complete preparation of structural components and construction to our own design.

Another system upon which we have recently embarked is to use indigenously made structures of • strength similar to those imported, although of different section. These sections are being made in semiprefabricated form by a central government workshop and we are building 25 bodies from them. Later, we will be able to manufacture our own structural cornponents. Orders have been placed for the machinery. My stores organization consists of a central store in Bombay, divided into branches for vehicle spares, consumable stores and general stores (furniture, stationery and so on). There is a headquarters stores in each division with satellite sub-stores at each depot. I am trying to keep depot repair work to a minimum by means of assembly exchange, but because of an insufficient float of assemblies at depot stores and a high rate of defects, I have not yet been able to reach my objective.

With 11 different makes of vehicle and many different models in operation, the reader can imagine the size of our problem in effective provisioning of spares and keeping down the number of vehicles off the road. Our greatest obstacles have been import restrictions and a high incidence of usage of spare parts because of operational conditions.

We started operation in one area with 50 buses of one make. Within a month, 42 were lying idle with broken front-spring-main leaves. 'In another area, another make of vehicle suffered a fracture of about 60 front stub-axles because the springs were unsuitable. With this same make, the shackle pins stand up for only a few miles. I have had the stub-axle trouble with a different make, but not to the same extent.

Another make ran into a spate of fractured steering arms. Although these were made by one of the leading British component manufacturers, they could not stand up to our conditions. One make suffered badly with rearspring front-hanger breakages and direct-gear slidingdog teeth shearing off. Two other makes have had a run of chassis side-member fractures.

Because of the dusty conditions, injection-pump troubles occur, despite concerted efforts to keep the fuel clean. The rate of replacements is high. For every 100 vehicles, 15 spring leaves break every day.

I have described the mechanical side of the State transport organization, the handicaps under which it works and the servicing system adopted to cope with the rigorous operational conditions. This organization will soon attain a standard,. of efficiency that will make it an example to be followed by other States now contemplating or launching upon nationalizatioA.