GERMAN DESIGNERS ON THEIR TOES

Page 40

Page 41

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

By L. J. COTTON, m.i.R.T.E.

GERMAN technicians have since the war been extremely busy and their. present standard of chassis design is high. There could be no suggestion of improving current tnodels,. because they were non-existent by 1945, so designers started afresh with a clean sheet of paper on the drawing board. The unit that has, for the present, escaped attention is the oil engine., which requires further research and development, but great progress may be made within a year or so.

The driver of most German indirect-injection oilengined vehicles has to be rather more observant than his British contemporary, because manual advance of the fuel-injection pump is common, and independent use is made of a blind in front of the radiator to improve engine performance.

Raising Output by Supercharging M.A.N. is one of the pioneers in Germany of the direct-injection engine, and a new development is the V8 engine of 11.6-litre capacity and 180 b.h.p. otitput. This has been designed for a 19-ton normal-control four-wheeler. The power unit has the cylinder banks arranged at 90 degrees. A further M.A.N. development is to supercharge the six-cylindered 8.72-litre engine, which raises the output, in its normally aspirated form, from 130 b.h.p. to •175 b.h.p. at 2,000 r.p.m.

Operated by the exhaust gas, the turbo-supercharger supplies a boost pressure of 6 lb. to 7.5 [b. per sq. in. at a turbo speed of 35,000 r.p.m. With the manifolds on opposite sides of the cylinder heads, this requires an extension to the inlet branch, which is taken round the front of the power unit and finned. With increased use of light alloys, the additional weight of 1 cwt. might be reduced by a third.

The maintenance of a cold-air supply for combustion and dispersing under-bonnet heat has received attention. Some of the German rear-engined coaches draw the air supply from ducts in the side or roof of the body, and the Bussing underfloor-engined unit employs a large filter mounted forward of the front axle. Henschel, with the power unit mounted conventionally ahead of the driver, reduces under-bonnet temperature by employing side panels of expanded metal in the top cover.

The Bussing underfloor unit is one of the few German engines developed since the war and, although it is Bb shallow and its auxiliaries are well placed, it still retains the pre-combustion chamber in the cylinder head. Minor modifications have been made to the power unit and chassis frame since the prototype was produced,•the latest developments including taking air for combustion through ports in the valve-rocker cover and fitting caster wheels underneath the main casting for ease of removal. The depth of the flywheel housing has been slightly reduced, and the rear of the frame downswept to provide a lower platform. It is conceivable that other slight alterations may be in hand further to reduce frame height, because a six-wheeled double-decker with an underfloor power unit is planned.

Some advance in gearbox design is found in the medium and heavy classes of chassis, particularly the ZF automatic unit used in buses and coaches. This box has all the advantages of a self-change unit, but without loss of efficiency. It is said to be expensive to install and has yet to be proved in town Operation. In principle, the multi-plate clutches, actuated electromechanically and running in oil, should be satisfactory

and free from wear or distortion. • New Selector Arrangement The ZF conventional box for goods vehicles is popular, and the selector arrangement, as used in the M.A.N. 19-tonner, is novel. The tower power-weight ratio of heavy vehicles necessitates frequent gear changes, and the arrangement of the selector gate in the M.A.N. minimizes the travel of the gear lever. The gate is. in effect, turned at right angles to the normal position, with neutral in the centre.

To obtain first or second gears, the lever is depressed and moved forward or back, returning to the neutral position to be moved to the third or fourth ratios;, a light spring pressure has to be overcome to raise the lever for the fifth and six gears. Apart from the reverse position, the lever travel is the same for all gears, approximately 4 ins, of movement being required, Henschel has introduced the preseleetive auxiliary gearbox in the new 4-tonner, thus providing 10 forward speeds. The ratios of the main and auxiliary boxes are arranged in half-steps, and preselective engagement is obtained by spring loading a sliding dog which engages constant-mesh gears. Another Henschel transmission development is the flat-top, worm-gear housing, which -permits a lower gangway level in passenger chassis. This final-drive unit, made under licence from David Brown of Huddersfield, has an overhead worm with a double reduction through helical gears, outrigged from the worm wheel and differential, and meshing with gears splined to the half-shafts. Thus, the drive is taken down to the worm wheel and returned to the half-shafts, which are located at worm level. Mainly, the doublereduction helical drive is employed in German design.

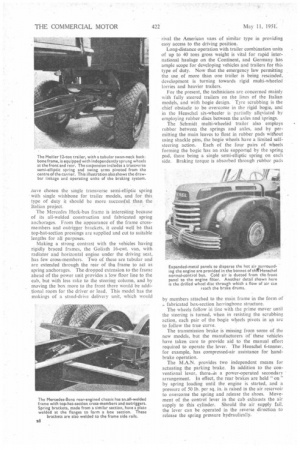

Independent front suspension'is standard in cars and vans based on similar chassis in most countries, but its use in commercial vehicles designed as such is not common, apart from the D.K..W., Auto Union and the Tempo Matador, which have independent suspension for all wheels. The latest German makes to be won over to independent front suspension include the Gutbrod, which now has twin transverse semi-elliptic springs at the front supporting the stub axles direct, and the Goliath 16-cwt. four-wheeler. This has a single transverse semi-elliptic spring which forms the lower anchorage of the swivel and has a single wishbone on each side at the top.

Three years ago Alfa Romeo produced an independent front suspension system on an 8-tonner, but was forced to abandon it because of excessive tyre wear. This warning of difficulties to be overcome in its employment on heavy prime movers has not passed unnoticed in Germany, and although no move is yet apparent to introduce it in lorries or buses, the system has been adopted for trailers. Rathgeber and MeiIler nave chosen the single transverse semi-elliptic spring with single wishbone for trailer models, and for this type of duty it should be more successful, than the Italian project.

The Mercedes Heck-bus frame is interesting because of its all-welded construction and fabricated spring anchorages. From the appearance of the frame crossmembers and outrigger brackets, it could well be that top-hat-section pressings are supplied and cut to suitable lengths for all purposes.

Making a strong contrast with the vehicles having rigidly braced frames, the Goliath I6-cwt. van, with radiator and horizontal engine under the driving seat, has few cross-members. Two of these are tubular and are extended through the rear of the, frame to act as spring anchorages. The dropped extension to the frame ahead of the power unit provides a low floor line to the cab, but with less rake to the steering column, and by moving the box more to the front there would be additional room for the driver or load. This model has the makings of a stand-drive delivery unit, which would rival the American vans of similar type in providing easy access to the driving position.

Long-distance operation with trailer combination units of up to 40 tons gross weight is vital for rapid international haulage on the Continent, and Germany has ample scope for developing vehicles and trailers for this type of duty. Now that the emergency law permitting the use of more than one trailer is being rescinded. development is turning towards rigid multi-wheeled lorries and heavier trailers.

For the present, the technicians are concerned mainly with fully steered trailers on the lines of the Italian models, and with bogie design. Tyre scrubbing is the chief obstacle to be overcome in the rigid bogie, and in the Henschel six-wheeler is partially alleviated by employing rubber discs between the axles and springs.

The Schmidt multi-wheeled trailer also employs rubber between the springs and axles, and by permitting the main leaves to float in rubber pads without using shackle pins, the bogie wheels have a limited selfsteering action. Each of the four pairs of wheels forming the bogie has an axle supported by the spring pad, there being a single semi-elliptic spring on each side. Braking torque is absorbed through rubber pads

by members attached to the main frame in the form of fabricated box-section herringbone structure.

The wheels follow in line with the prime mover until the steering is turned, when in resisting the scrubbing action, each pair of the bogie wheels pivots in an arc to follow the true curve.

The transmission brake is missing from some of the new models, but the manufacturers of' these vehicles have taken care to provide aid to the manual effort required to operate the lever. The Henschel 6-tonner. for example, has compressed-air assistance for hand brake operation.

The M.A.N. provides two independent means for

actuating the parking brake. In addition to the conventional lever, there—is a power-operated secondary ' arrangement. In effect, the rear brakes are held " on " by spring loading until the engine is started, and a pressure of 50 lb. per sq. in. is raised in the air reservoir to overcome the spring and release the shoes. Movement of the control lever in the cab exhausts the air supply to this cylinder. Should the air supply fail, the lever can be operated in the reverse direction to release the spring pressure hydraulically.