Oil Circulation in the New Daimler Oil Engine

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

WiEN dealing with the new Daimler 8.6-litre oil engine in our issue dated April 27, particular attention was

drawn to the extremely thorough provision ntade for effective lubrication.

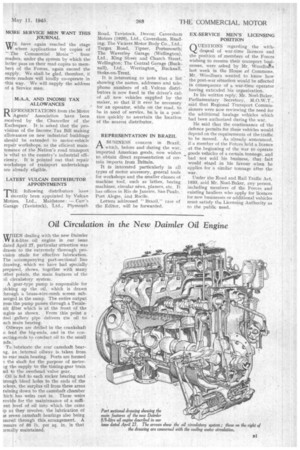

The accompanying part-sectional line drawing, which we have had specially prepared, shows, together with many Dther points, the main features of the jil circulatory system.

A gear-type pump is responsible for picking up the oil, which is drawn lrough a brass-wire-mesh screen sub

merged in the sump. The entire output .rom the pump passes through a Tecale nit filter which is at the front of the r-ig-ine as shown. From this point a tee gallery pipe delivers the oil to :ach main bearing.

Oilways are drilled in the crankshaft o feed the big-ends, and in the conrecting-rods to conduct oil to the small nds.

To lubricate the rear camshafrt bearng, an internal oilway is taken from he rear main bearing. Ports are formed a the shaft for the purpose of meterag the supply to the timing-gear train nd to the overhead valve gear.

Oil is fed to each rocker bearing and Etrough bleed holes to the ends of the -miters, the surplus oil from these areas raining down to the camshaft chamber inch has weirs cast in. These weirs rovide for the maintenance of a suffient level of oil into which the cams ip as they revolve, the lubrication of le seven camshaft bearings also being isured' through this arrangement. A 7essure of 60 lb. per sq. in. is that )1-malty maintained.