TRANSPORT IN '

Page 16

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

IMBER . TRADE.

TEE USE of motor vehicles has gradually extended in recent years until, at the present time, there is hardly a trade in the country which does not use the petrol engine in some way or other. The timber trade is no exception to this rule, and we were recently able to inspect the largest timber yard and sawmills in this country with a view to examining the transport system and the way in which the various hardwoods dealt with are stored and seasoned.

This yard is owned by J. Gliksten and Son, Ltd., and is situated near Stratford (London). Timber coming from overseas is transferred from the ships to barges at the Surrey Commercial Docks, and is then brought via the canals to the wharves of the timber yard. Here it is unloaded by means of largd travelling cranes and placed uppn trailers, the capacity of which amounts to five or six tons. Over 40 of these trailers are used for handling timber in the yards, and they are hauled from point to point by a number of Austin tractors. This system has proved itself to be very flexible and economical, it being possible to keep the tractors fully employed in haulage whilst some of the trailers are being loaded and unloaded.

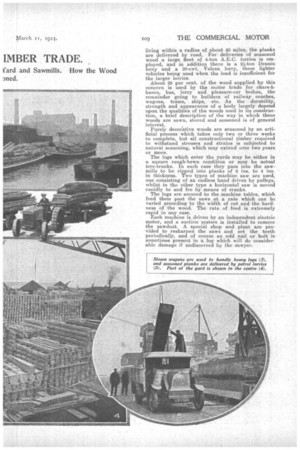

The tractors are very handy to operate and can turn in a remarkably small radius. Home-grown timber is also brought iuto the yards, this arriving at a neighbouring railway goods siding, from which it is conveyed by 6-ton Foden steam wagons. These sturdy units have proved very efficient in handling heavy logs, the bodies being provided with steel joists which support the logs in an inclined position. • The importance of the system of internal transport will be realized when it' is stated that the yards cover 36 acres, extending for a distance of over two miles, and contain timber to a value of more than 000.000. The new wood coming in has all to pass through the sawmill and must then be taken to the yards and stored for seasoning. The duties of the fleet do not end here, because wood required for customers must be brought from the stock and delivered to the railway, or, in the case of customers living within a radius of about 40 miles, the planks are delivered by road. For deliveries of seasoned wood a large fleet of 4-ton A.E.C. lorries is employed, and in addition there is •a *ton Dennis lorry and a 30-cwt. Vulcan lorry, these lighter vehicles being used when the load is insufficient for the larger lorries. About 25 per cent. of the wood supplied by this concern is used by the motor trade for chars-I-banes, bus, lorry and pleasure-car bodies, the remainder going to builders of railway coaches, wagons, trams, ships, etc. As the durability, strength and appearance of a body largely depend upon, the qualities of the woods used in its construction, a brief description of the way in which these woods are sawn, stored and seasoned is of general interest. . Purely decorative woods are seasoned by an artificial process which takes only two or three weeks to complete, but all constructional timber required to withstand stresses and strains is subjected to natural seasoning, which may extend over two years or more.

The logs which enter the yards may be either in a square rough-hewn condition or may be actual tree-trunks. In each case they pass into the sawmills to be ripped into planks of 2 ins. to 4 ins. in thickness. Two types of machine saware used, one consisting of an endless hand driven by pulleys, whilst in the other type a horizontal saw is moved rapidly to and fro by means of cranks.

The logs are secured to the machine tables, which feed them past the saws at a rate which can be varied aecording to the width of cut and the hardness of the wood. The rate of feed is extremely rapid in any case.

Each machine is driven by an independent electric motor, and a suction system is installed to remove the sawdust. A special shop and plant are provided to resharpen the saws and set the teeth periodically, and of course an odd nail or bolt is sometimes present in a log which will do considerable damage if undiseoverd by the sawyer.

A clever grinding machine is used to sharpen the saws, which passes them under a rising and falling grinding wheel tooth by tooth, taking a "skim " off each and producing the required degree of rake. Subsequently, the teeth are set over at an angle by hand.

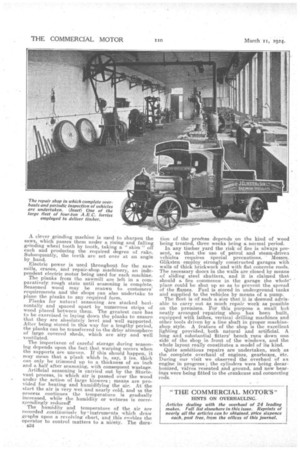

Electric power is used throughout for the sawmills, cranes, and repair-shop machinery, an independent electric motor being used for each machine. The planks from the sawmill are left in a comparatively rough state until seasoning is complete. Seasoned wood may be resawn to customers' requirements and the shops can also undertake to plane the planks to any required form. Planks for natural seasoning are stacked horizontally and spaced apart by numerous strips of wood placed between them. The greatest care has to be exercised in laying down the planks to ensure that they are absolutely level and well supported. After being stored in this way for a lengthy period, the planks can be transferred to the drier atmosphere of large covered sheds, which are airy and well ventilated.

The importance of careful storage during seasoning depends upon the fact that warping occurs when the supports are uneven. If this should happen, it may mean that a plank which is, say, 2 ins, thick can only be trimmed up to a thickness of an inch and a half after seasoning, with consequent wastage. Artificial seasoning is carried out by the Sturtevant process, in which air is passed over the wood under the action of large blowers ; means are provided for heating and humidifying the air. At the start the air is very wet and nearly cold, and as the Process continues the temperature is gradually increased, while the humidity or wetness is correspondingly reduced'.

The humidity and temperature of the air are recorded ,continnOuslv, by i instruments which draw graphs upon a revolving chart, and .this enables the operator to control matters to a nicety. The dura

B34 tion of the proeess depends on the kind of wood being treated, three weeks being a, normal period. In any timber yard the risk of fire is always present, so that the use of petrol and steam-driven vehicles requires special precautions. Messrs. Gliksten employ strongly constructed garages with walls of thick brickwork and with flat concrete roofs. The necessary doors in the walls are closed by means of sliding steel shutters, and it is claimed that should a fire commence in the garage the whole place could be shut up so as to prevent the spread of the flames. Fuel is stored in underground tanks and supplied to the vehicles by means of a pump. The fleet is of such a size that it is deemed advisable to carry out as much repair work as possible on the premises. For this purpose a small but neatly arranged repairing shop has been built, equipped with lathes, vertical drilling machines and other tools driven by a line shaft in proper machineshop style. A feature of the shop is the excellent lighting provided, both natural and artificial. A long and substantial fitters' bench runs down one side of the shop in front of the windows, and the whole layout really constitutes a model of its kind. Quite ambitious repairs are undertaken, such as the complete overhaul of engines, gearboxes, etc. During our visit we observed the overhaul of an engine in progress ; the cylinders were being decarbonized, valves resented and ground, and new bear. ings were being fitted to the crankcase and connecting rods.