GETTING A GRIP

Page 111

If you've noticed an error in this article please click here to report it so we can fix it.

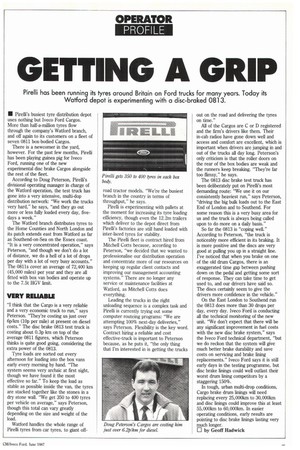

• Pirelli's busiest tyre distribution depot uses nothing but Iveco Ford Cargos. More than half-a-million tyres flow through the company's Watford branch, and off again to its customers on a fleet of seven 0811 box-bodied Cargos.

There is a newcomer in the yard, however. For the past few months, Pirelli has been playing guinea pig for Iveco Ford, running one of the new experimental disc brake Cargos alongside the rest of the fleet.

According to Doug Peterson, Pirelli's divisional operating manager in charge of the Watford operation, the test truck has gone into a very intensive, multi-dop distribution network: "We work the trucks very hard," he says, "and they go out more or less fully loaded every day, fivedays a week."

The Watford branch distributes tyres to the Home Counties and North London and its patch extends east from Watford as far as Southend-on-Sea on the Essex coast. "It is a very concentrated operation," says Peterson, "and though we don't do a lot of distance, we do a hell of a lot of drops per day with a lot of very busy accounts." The 0811s cover an average of 72,400 km (45,000 miles) per year and they are all fitted with box van bodies and operate up to the 7.5t HGV limit.

"I think that the Cargo is a very reliable and a very economic truck to run," says Peterson. "They're costing us just over 6p/km (10p per mile) at present on diesel costs." The disc brake 0813 test truck is costing about 0.3p km on top of the average 0811 figures, which Peterson thinks is quite good going, considering the extra power of the 0813.

Tyre loads are sorted out every afternoon for loading into the box vans early every morning by hand. "The system seems very archaic at first sight, though we have found it the most effective so far." To keep the load as stable as possible inside the van, the tyres are stacked together like the stones in a dry stone wall. "We get 350 to 400 tyres per vehicle on average," says Peterson, though this total can vary greatly depending on the size and weight of the load.

Watford handles the whole range of Pirelli tyres from car tyres, to giant off road tractor models. "We're the busiest branch in the country in terms of throughput," he says.

Pirelli is experimenting with pallets at the moment for increasing its tyre loading efficiency, though even the 12.2m trailers which deliver to the depot direct from Pirelli's factories are still hand loaded with inter-laced tyres for stability.

The Pirelli fleet is contract hired from Mitchell Cotts because, according to Peterson, "we decided that we wanted to professionalise our distribution operation and concentrate more of our resources on keeping up regular client contacts and improving our management accounting systems." There are no longer any service or maintenance facilities at Watford, as Mitchell Cotts does everything.

Leading the trucks in the right unloading sequence is a complex task and Pirelli is currently trying out some computer routeing programs: "We are attempting 100% next-day deliveries," says Peterson. Flexibility is the key word. Contract hiring a reliable and cost effective-truck is important to Peterson because, as he puts it, "the only thing that I'm interested in is getting the trucks out on the road and delivering the tyres on time."

All of the Cargos are C or D registered and the firm's drivers like them. Their in-cab radios have gone down well and access and comfort are excellent, which is important when drivers are jumping in and out of the trucks all day long. Peterson's only criticism is that the roller doors on the rear of the box bodies are weak and the runners keep breaking. "They're far too flimsy," he says.

The 0813 disc brake test truck has been deliberately put on Pirelli's most demanding route: "We use it on our consistently heaviest run," says Peterson, "driving the big bulk loads out to the East End of London and to Southend. For some reason this is a very busy area for us and the truck is always being called upon to do more on a daily basis."

So far the 0813 is "coping well." According to Peterson, "the truck is noticeably more efficient in its braking. It is more positive and the discs are very good at pulling you up in a straight line. I've noticed that when you brake on one of the old drum Cargos, there is an exaggerated time gap between pushing down on the pedal and getting some sort of response. They can take time to get used to, and our drivers have said so. The discs certainly seem to give the drivers more confidence in the vehicle."

On the East London to Southend run the 0813 does more than 30 drops per day, every day. Iveco Ford is conducting all the technical monitoring of the new unit. "We don't expect that there will be any significant improvement in fuel costs with the new disc brake system," says the Iveco Ford technical department, "but we do reckon that the system will give much better brake durability and save costs on servicing and brake lining replacements." Iveco Ford says it is still early days in the testing programme, but disc brake linings could well outlast their worst drum lining competitors by a staggering 150%.

In tough, urban multi-drop conditions, Cargo brake drum linings will need replacing every 25,000km to 30,000Ian and disc linings could improve this at least 55,000km to 60,000km. In easier operating conditions, early results are pointing to disc brake linings lasting very much longer. D by Geoff Hadwick