Hoynor's answer to chassis transport

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

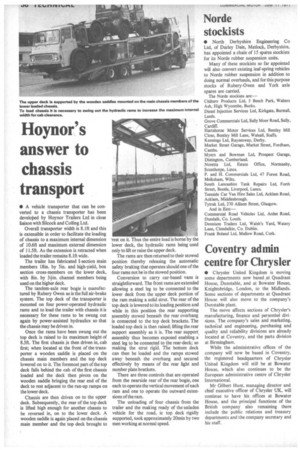

• A vehicle transporter that can be converted to a chassis transporter has been develobed by Hoynor Trailers Ltd in close liaison with Sikock and Coiling Ltd.

Overall transporter width is 8.1ft and this is extensible in order to facilitate the loading of chassis to a maximum internal dimension of 10.611 and maximum external dimension of 11.511. As the extension is retracted when loaded the trailer remains 8.1ft wide.

The trailer has fabricated I-section main members 18in. by 5in. and high-yield, box section cross-members on the lower deck, with 8in. by 3-1-in. channel members being used on the higher deck.

The tandem-axle rear bogie is manufactured by Rubery Owen as is the full air-brake system. The top deck of the transporter is mounted on four power-operated hydraulic rams and to load the trailer with chassis it is necessary for these rams to be swung out again by power-assisted hydraulics so that the chassis may be driven in.

Once the rams have been swung out the top deck is raised to its maximum height of 8.5 ft. The first chassis is then driven in, cab first; when located at the front of the transporter a wooden saddle is placed on the chassis main members and the top deck lowered on to it. The foremost part of the top deck falls behind the cab of the first chassis loaded and the deck then pivots on the wooden saddle bringing the rear end of the deck to rest adjacent to the run-up ramps on the lower deck.

Chassis are then driven on to the upper deck. Subsequently, the rear of the top deck is lifted high enough for another chassis to be reversed in, on to the lower deck. A wooden saddle is again placed on the chassis main member and the top deck brought to 'rest on it. Thus the entire load is borne by the lower deck, the hydraulic rams being used only to lift or raise the upper deck.

The rams are then returned to their stowed position thereby releasing the automatic safety braking that operates should one of the four rams not be in the stowed position.

Conversion to carry car-based vans is straightforward. The front rams are extended allowing a steel leg to be connected to the lower deck from the upper deck portion of the ram making a solid strut. The rear of the top deck is lowered td its loading position and while in this position the rear supporting assembly stowed beneath the rear overhang is connected to the top deck brackets. The loaded top deck is then raised; lifting the rear support assembly as it is. The rear support assembly thus becomes exposed enabling a steel leg to be connected to the rear-deck; so making the strut rigid. The bottom deck can then be loaded and the ramps stowed away beneath the overhang and secured effectively by means of the rear light and number plate bratkets.

There are three controls that are operated from the nearside rear of the rear bogie, one each to operate the vertical movement of each ram and one to operate the outward extensions of the ram.

The unloading of four chassis from the trailer and the making ready of the unladen vehicle for the road, ie top deck rigidly supported, took approximately 20min by two men working at normal speed.