The MacCord Mechanical Lubricator.

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

One of the most fruitful sources of trouble, in connection with the employment of petrol engines for commercialvehicle purposes, has been the inefficiency of the lubricating systems embodied by some manufacturers. The original and simplest form of splash lubrication, in the early days of commercial motor enterprise, gave considerable trouble, and engineers immediately turned to the mechanical lubricator as a solution of their difficulties.

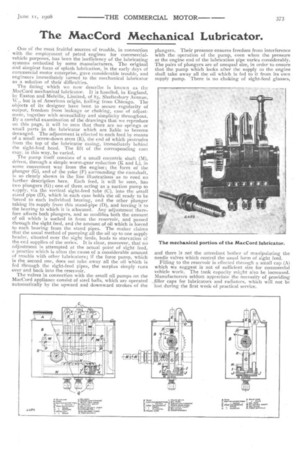

The fitting which we now describe is known as the MacCord mechanical lubricator. It is handled, in England, by Easton and Melville, Limited, of 85, Shaftesbury Avenue, W., but is of American origin, hailing from Chicago. The objects of its designer have been to secure regularity of output, freedom from leakage or choking, ease of adjustment, together with accessibility and simplicitythroughout. By a careful examination of the drawings that we reproduce on this page, it will be seen that there are no springs or small parts in the lubricator which are liable to become deranged. The adjustment is effected to each feed by means of a small screw-down stem (E), the end of which protrudes from the top of the lubricator casing, immediately behind the sight-feed hood. The lift of the corresponding cam may in this way, be varied.

The pump itself consists of a small eccentric shaft (M), driven, through a simple worm-gear reduction (K and L), in some convenient way from the engine; the form of the plunger (G), and of the yoke (F) surrounding the camshaft, is so clearly shown in the line illustrations as to need no further description here. Each feed, it will be seen, has two plungers (G); one of them acting as a suction pump to supply, via the vertical sight-feed tube (C), into the small stand pipe (D), which in each case holds the oil ready to be forced to each individual bearing, and the other plunger taking its supply from this stand-pipe (D), and forcing it to the bearing to which it is allocated. Any adjustment therefore affects both plungers, and so modifies both the amount of oil which is sucked in from the reservoir, and passed through the sight feed, and the amount of oil which is forced to each bearing from the stand pipes. The maker claims that the usual method of pumping all the oil up to one supply header, situated over the sight feeds, leads to starvation of the end supplies of the series. It is clear, moreover, that no adjustment is attempted at the actual point of sight feed, a practice which is often the cause of a considerable amount of trouble with other lubricators; if the force pump, which is the second one, does not take away all the oil which is fed through the sight-feed pipes, the surplus simply runs over and back into the reservoir.

The valves in connection with the small oil pumps on the MacCord appliance consist of steel balls, which are operated automatically by the upward and downward strokes of the

plungers. Their presence ensures freedom from interference with the operation of the pump, even when the pressure at the engine end of the lubrication pipe varies considerably. The pairs of plungers are of unequal size, in order to ensure that the pump which looks after the supply to the engine shall take away all the oil which is fed to it from its own supply pump. There is no choking of sight-feed glasses,

and there is not the attendant bother of manipulating the needle valves which control the usual form of sight feed.

Filling to the reservoir is effected through a small cap (A) which we suggest is not of sufficient size for commercial vehicle work. The tank capacity might also be increased. Manufacturers seldom appreciate the necessity of providing filler caps for lubricators and radiators, which will not be lost during the first week of practical service.