50 m.p.h.

Page 51

Page 50

Page 52

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

25-tonner

By John F. Moon, A.M.I.R.T.E.

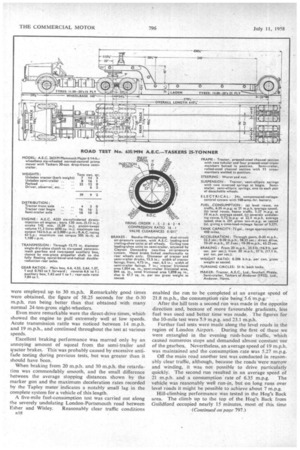

AMAXIMUM speed approaching 50 m.p.h. makes the A.E.C. 40-ton-gross prime mover a likely choice for overseas operators requiring a vehicle to move 25 tons over long distances in the shortest possible time. Good acceleration assists in maintaining a high cruising speed. whilst an excellent braking system enables it to be driven in safety.

• The tractor unit was tested with a Taskers 30-ton drop: frarrie iemi-trailer carrying a payload of just over 221 tons, th'e gross train weight being 39 tons 91 cwt. This is 101 cwt. belOw " the manufacturer's maximum. recommended weight and, because the 30-ton trailer is about 3 tons heavier than the 25-ton trailer which would normally have been used with the tractor, it should be possible to carry a payload of -about 26 tons with this oufflt under favourable

conditions. . •

The A.E.C. Mammoth Major 6 is a normal-controi design, and -should satisfy the requirements of foreign operator's to whom good engine accessibility and a reason ably cool and unobstructed cab are of more importat.ce than minimum overall length. The chassis is powered by the A.E.C. 113-litre six-cylindered oil engine which, in the case of the test. vehicle, was governed at 2,000 r.p.m., instead of its normal1,800 r.p.m. At the higher speed 165 gross b.h.p. is' developed (162 net b.h.p.), compared with the 150 gross b.h.p. when governed at 1,800 r.p.m.

There are many transmission variations available with this chassis. It can have a fiveor six-speed constant-mesh B16 main gearbox, an auxiliary gearbox, and a choice of two fully articulated double-drive bogies, one having overslung worm-drive axles with a third differential, and the other having spiral-bevel and double-helical double-reduction axles and no third differential.

The vehicle offered for test had the six-speed overdrivetop main gearbox, the auxiliary gearbox and the doublereduction axles. It was also equipped with a large-capacity radiator and oil cooler, this being standard when the auxiliary gearbox is fitted.

Despite the provision of 12 forward ratios the hill performance of the A.E.C. was somewhat disappointing, but it was just possible to make a smooth restart on a 1-in-6-1 gradient. As several of the overall ratios in highand low-auxiliary are extremely close, there are only about eight useful ratios. If the low-auxiliary ratio were nearer 2 to I. instead of 1,62 to I, the overall utility of the transmission would be improved, and gradient ability would be more suited to an overseas tractor of this type. .

Air-pressure braking is standard on the A.E.C. tractor and a split circuit is employed. With this the front and left-hand rear brakes are

actuated by one circuit, and the Tight-hand rear and semitrailer brakes are actuated by the other circuit. The reason for the -rear braking being split between sides and not axles is that two air cylinders, one on each side, operate all four brakes through a cross-linkage. Although not fitted to the test vehicle, a hand-reaction valve for the semi-trailer brakes is available and would, in my opinion, be a useful standard fitting on a vehicle of this size.

Another item of optional equipment not fitted to the test vehicle, but sadly missed, was power steering. The steering of the tractor makes it extremely heavy to manceuvre at any speed and the lack of castor action causes a pronounced tendency to wander when on the open road, demanding constant correction at the steering wheel. I find it hard to account for the heaviness of the steering, particularly as the front-axle loading was little more than 4 tons.

The tractor is offered with a wheelbase of 17 ft. 3+ in., or of 14 ft. as tested. As a load carrier it is suitable for a gross vehicle weight of 24 tons, the front-axle limit being 5 tons. As tested, the kerb weight of the chassis without cab was 7 tons 14+ cwt., whilst the Taskers semi-trailer, which was extremely robust, weighed 8 tons 161 cwt. including a Thompson 7-ton winch, but excluding spare wheel and loading ramps.

Hampton Court Way was used for braking and acceleration tests. The acceleration figures quoted were obtained with the auxiliary gearbox in high ratio (direct drive), and from a standing start second, third, fourth and fifth gears were employed up to 30 m.p.h. Remarkably good times were obtained, the figure of 58.25 seconds for the 0-30 m.p.h. run being better than that obtained with many normal 24-ton-gross eight-wheelers.

Even more remarkable were the direct-drive times, which showed the engine to pull extremely well at low speeds. Acute transmission rattle was noticed between 14 m.p.h. and 19 m.p.h., and continued throughout the test at various speeds.

Excellent braking performance was marred only by an annoying amount of squeal from the semi-trailer and tractor brakes. This was probably caused by excessive antifade testing during previous tests, but was greater than it should have been.

When braking from 20 m.p.h. and 30 m.p.h. the retardation was commendably smooth, and the small difference between the average stopping distances shown by the marker gun and the maximum deceleration rates recorded by the Tapley meter indicates a notably small lag in the complete system for a vehicle of this length. . A five-mile fuel-consumption test was carried out along the severely undulating London-Portsmouth road between

Esher and Wisley. Reasonably clear traffic conditions R 18 enabled the run to be completed at an average speed of 21.8 m.p.h., the consumption rite being 5.6 m.p.g.

After the hill tests a second run was made in the opposite direction and, because of more favourable gradients, less fuel was used and better time was made. The figures for the 10-mile test were '5.9 m.p.g. and 23.1 m.p.h.

Further fuel tests were made along the level roads in the region of London Airport. During the first of these we were entangled in the evening rush-hour traffic, which caused numerous stops and demanded almost constant use of the gearbox. Nevertheless, an average speed of 19 m.p.h. was maintained and the consumption. rate was 5.27 m.p.g.

Off the main road another test was conducted in reasonably clear traffic, although, because the roads were narrow and winding, it was not possible to drive particularly quickly. The second run resulted in an average speed of 21 m.p.h. and a consumption rate of 6.35 m.p.g. The vehicle was reasonably well run-in, but on long runs over level roads it might be possible to achieve about 7 m.p.g.

Hill-climbing performance was tested in the Hog's Back area. The climb up to the top of the Hog's Back from Guildford occupied nearly 15 minutes. most of this time being spent in third gear. According to the temperature gauge in the instrument panel the water in the cylinder heads attained a temperature of well over 200° F. At this temperature, however, the thermostat in the cooling system was only just fully open, and longer and steeper climbs should not cause high coolant temperatures.

The outfit was then shunted down a side road where the gradient is 1 in 6.4and here it was stopped. The powerful multi-pull hand brake on the tractor was sufficient to hold the complete outfit on this slope. The semi-trailer hand brakes were then applied and the tractor brakes released, but they were not quite capable of holding the vehicle. The brakes on the semi-trailer are Girling two-leading-shoe units, but the two-leading-shoe effect operates only with forward motion. Had the outfit been facing down the hill the semi-trailer brakes would almost certainly have held it.

With bottom gear, low auxiliary, engaged, several fullthrottle restarts were made on this gradient, but care was necessary when engaging the clutch. On one occasion I engaged it rather too quickly and the front wheels left the ground completely with the sudden application of torque.

Further attempts to restart were made with second low and first high engaged, but neither of these was successful. Excessive clutch slipping resulted on each ocCasion, culminating in the engine stalling with the take-up of drive.

The descent from the Hog's Back was made at 20 m.p.h. with the brakes lightly applied and top gear engaged. This test lasted about five minutes, and at the end of this time there was no obvious signs of fade having taken place.

Apart from the heaviness of the steering the outfit handled welt on the road, despite its length, and the suspension seemed good. Tilt semi-trailer rode well and at no time was I conscious of there being any bucking or bouncing at the fifth wheel.

For normal road work it is unnecessary to use the low ratio of the auxiliary gearbox, the outfit starting comfortably in second gear high ratio. The good top-gear performance of the engine reduces the amount of gear changing necessary on level roads.

On the second day of the test a series of maintenance tasks was conducted-on the chassis and semi-trailer. First the semi-trailer was disconnected, welcome assistance being provided by Mr. Russell Doughty of Taskers. Although I had been prepared to jack up the front of the semi-trailer to uncouple it, I was assured that this was unnecessary. Two wooden blocks, about 1 in, lower than the underside of the frame, were placed beneath it, the tractor turntable coupling was released and the chassis driven away, the whole operation taking only three minutes.

[then adjusted the four semi-trailer brakes in 3 minutes 23 seconds. Each brake had a single square-headed adjuster. It was unnecessary to jack up the wheels: Next We .removed the two sets of semi-trailer wheels in 4 minutes 41 seconds, this time including jacking-up with two Skyhi hydraulic jacks each weighing about 31 cwt. With the weight of the end of the semi-trailer taken by these jacks it was necessary only to release the air pressure, disconnect the air hoses, slacken off the two large securing nuts at the end of each wheel assembly, raise the semitrailer another couple of inches, and roll the wheels out.

Replacement of the semi-trailer wheels took a little longer —71 minutes—because slight difficulty was experienced in aligning one set of wheels so that the trunnion stub entered centrally the trunnion bearing in the Semi-trailer frame. Even so, there was nothing difficult about both operations and the hardest work of all was moving and locating the two jacks.

I then turned my attention to the A.E.C.. Chassis and started by removing the two side bonnet panels in 15 seconds. The upper bonn'et panel is binged at the rear with a sturdy. built-in support and took 4 seconds to lift and secure.

The radiator-water level can be checked without disturbin any of the bonnet panels, the filler cap being concealed beneath the small hinged motif panel. This is secured by a Dzus fastener and I verified the level in 25 seconds. Following this I checked the engine-oil level in 13 seconds, the dipstick and filler being reachable from the near side.

Crawling underneath the vehicle I tested the main gearbox oil level through the combined level and filler plug in 21 minutes. The levels in the leading and trailing rearaxles were checked in 38 seconds and 59 seconds respectively, the longer time being caused by a tight thread on the plug. I was unable to check the level in the auxiliary gearbox, because the plug thread was extremely tight and the closeness of the compressor drive shaft makes it difficult to obtain a proper purchase with a spanner.

With the bonnet top raised I then removed the air-cleaner bowl, checked its oil level and replaced the bowl in 31 minutes. It is secured by two barrel-type nuts which are easy to reach.

Working from the other side of the bonnet I removed No. 1 fuel injector in 3 minutes 10 seconds without any difficulty and replaced it in 3 minutes. All the injectors are easy to reach, and conventional open-ended spanners can be used on all the nuts and unions.

There are four filters in the fuel system two large feltelement units on the suction side and two paper-element filters on the delivery side. All the filters are easy to reach and I was able to remove one of the felt elements in 21 seconds and replace it in 29 seconds. Removal of one of the paper elements took 45 seconds and replacement 63 seconds. Thus, all the elements can be exchanged in little more than 5 minutes.

An A.E.C. fitter then 'adjusted the rear brakes for me, this being somewhat complicated because of all the rods. He used feelers to obtain the necessary clearance between facing and drums, and adjusted all four brakes in a total time of 15 minutes. The front brakes, which incorporate worm-type adjusters, were reset in 6 minutes. For none of these adjustments were the wheels jacked up.