A Petrol Engine with Oiler Characteristics

Page 50

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

By Laurence J. Cotton

M.I.R.T.E.

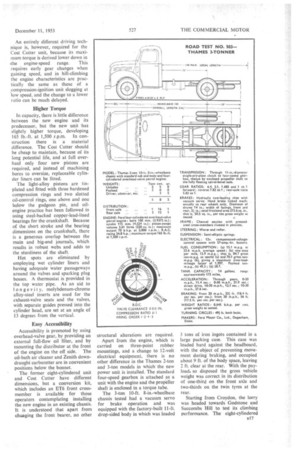

ACCORDING to a road-test report of just 18 years ago, when one of my predecessors was describing the Ford 2-3-tonner, the new V8 engine installed at that time provided abundant power and gave exceptional hill-climbing performance. The new "Cost Cutter" four-cylindered petrol unit, now fitted in the Thames 3-tonner, carries on the record of powerful performance, but with the notable distinction of greater economy. An entirely different driving technique is, however, required for the Cost Cutter unit, because its maximum torque is derived lower down in -the engine-speed range. This requires early gear changes when gaining speed, and in hill-climbing the engine characteristics are practically the same as those of a .compression-ignition unit slogging at low speed, and the change to a lower ratio can be much delayed.

Higher Torque

In capacity, there is little difference between the new engine and its predecessor, but the new unit has slightly higher torque, developing 165 lb.-ft. at 1,500 r,p.m. In con. struction there is a material difference. The Cost Cutter should be cheap to maintain, because of its long potential life, and at full overhaul only four new pistons are required, and instead of machining bores to oversize, replaceable cylinder liners can be fitted.

The light-alloy pistons are tinplated and fitted with three hardened compression rings and two slotted oil-control rings, one above and one below the gudgeon pin, and oilengine practice has been followed in using steel-backed copper-lead-lined bearings for the crankshaft. Because of the short stroke and the bearing dimensions on the crankshaft, there is a generous overlap between the main and big-end journals, which results in robust webs and adds to the sturdiness of the shaft.

Hot spots are eliminated by employing wet cylinder liners and having adequate water passageways around the valves and sparking plug bosses. A thermostat is provided in the top water pipe. As an aid to 1 onge v it y, molybdenum-chrome alloy-steel inserts are used for the exhaust-valve seats and the valves, with separate guides pressed into the cylinder head, are set at an angle of 13 degrees from the vertical.

Easy Accessibility

Accessibility is promoted by using overhead-valve gear, by providing an external full-flow oil filter, and by mounting the distributor at the front of the engine on the off side.. The oil-bath air cleaner and Zenith downdraught carburetter are in convenient positions below the bonnet.

The former eight-cylindered unit and Cost Cutter have different dimensions, but a conversion kit, which includes an ET6 front crossmember is available for those operators contemplating installing the new engine in an existing chassis. It is understood that apart from changing the front bearer, no other structural alterations are required.

Apart from the engine, which is carried on three-point rubber mountings, and a change to 12-volt electrical equipment, there is no other difference in the Thames 2-ton and 3-ton models in which the new power unit is installed. The standard four-speed gearbox is attached as a unit with the engine and the propeller shaft is enclosed in a torque tube.

The 3-ton 10-ft. 8-in.-wheelbase chassis tested had a vacuum servo for brake operation and was equipped with the factory-built 11-ft. drop-sided body in which was loaded 3 tons of iron ingots contained in a large packing case. This case was loaded hard against the headboard, with the object of preventing movement during braking, and occupied about 9 ft. of the body space, leaving 2 ft. clear at the rear. With the payload. so disposed the gross vehicle weight was correct in its distribution of one-third on the front axle and two-thirds on the twin tyres at the rear.

Starting from Croydon, the lorry was headed towards Godstone and Succombs Hill to test its climbing performance. The eight-cylindered engine formerly fitted was• notably quiet and smooth and it would be unreasonable to expect quite the same of the new power unit.

My first impression that the Cost Cutter Was reasonable in noise and free from vibration was borne out in 80 miles of road work. Its general behaviour is equal to that of the best of the four-cylindered breed.

Succombs Hill is a freak climb of just under half a mile, with sections of 1 in 5 and 1 in 41 near the bottom and top, and has a general gradient of 1 in 10 between. The. 1-in-5 incline enforced a rapid change to the lowest ratio, but although second gear was used at a more favourable point the engine speed fell slowly until almost every revolution could be counted as the speedometer needle hovered near 0 m.p.h. Just as the engine was about to stall 1 engaged low gear, and for good measure staged stop-start trials on the 1-in-4+ section.

During a repeat climb the hill was tackled with a flying start, but gear changes were still necessary at the same points as before. To become fully accustomed to the new engine before testing acceleration and fuel consumption, I drove into Godstone and then across country to Sevenoaks and back. The Thames handled well on the hills at Oxted and Westerham and climbed the 1-in-11 gradient of Riverhill in second gear.

Improved Acceleration

The high-speed engine formerly fitted in the 3-tonner afforded good acceleration through the gears, and the present engine carries on the tradition, whilst top-gear acceleration is improved.

With second gear engaged for starting and making a change to third gear at 19 m.p.h., 20 m.p.h. was reached in 11.4 sec. and 30 m.p.h. in 21.9 sec. • In the direct drive 12.1 sec. were required in accelerating from 10-20 m.p.h. and 27.6 sec. passed before the needle hovered over 30 m.p.h. on the scale. The distributor advance, incorporating governor weights and vacuum control, provided smooth acceleration from 8 m.p.h. in top gear without evidence of pinking on a standard commercial grade of petrol.

Consumption trials were staged between Godstone and East Grinstead, starting with a " dry " carburetter and running until' a measured half-gallon of petrol was exhausted. This course has average main-road undulations and is relatively free from slow-moving traffic or light signals.

On the first non-stop outward run 7.4 miles were covered in 19 min. and 7.7 miles were traversed before the engine indicated a fuel shortage on the return trip. This provided an average of 15.1 m.p.g. at 23.6 m.p.h. average speed.

The Ford representative, who had been driving on the first test, had been careful to conserve fuel, so I decided to try my skill over the same course, driving hard and making a stop at every mile. Economy was not as severely affected as I had expected and 6.1 miles .were run on the outward leg, and 6.8 miles on the teturn on two measured half-gallons of fuel. The average was 12.9 , m.p.g., which is what I would expect from a vehicle of this type if driven hard on short local journeys.

Compared with the V8 engine, the Cost Cutter unit in the 3-tonner appears to be well named, because calculated on a payload basis, it gives 45.3 ton-m.p.g., against 23.2 ton-mpg. These results suggest that it would be economical to put the four-cylindered engine into an existing chassis, especially if the eightcylindered unit could be held as a spare for use in an older chassis or in a Thames 5-tonner.