MAKING BEST USE OF THE FORD.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, which will Appeal to the Owner, Driver, and Repairer.

IN THIS series of hints concerning the Ford light chassis and ton truck wherever they are employed for commercial purpbses, we endeavour to deal with the subject from every view-point, so that the advice given will appeal to the owner, driver, maintenance engineer' or mechanic. Valuable sources of information are being tapped for this purpose, and it should be understood that the advice given will be derived from those with an intimate knowledge of the subject.

We shall welcome for inclusion among the hints those which have proved of value to individual users, and will make suitable remuneration for • any published. What we desire are the results of practice.

141.—A New and Curious Type of Segmental Distributor.

• A novel form of distributor is shown in the accompanying illustration and is designed to be run at a quarter engine speed.

The face of the distributor is equally divided into sixteen _segments, eight of which are wired up in pairs. The remaining eight act only as surface plates and are, therefore, not wired up.

As the distributor runs at quarter engine speed it will be understood that for every half revolution, of the contact arm over the segments the engine would have completed its order of firing on all four cylinders.

The advantages therein are that a much smoother and more instantaneous sequence of firing takes place ; moreover, the slow speed of the distributor arm and main bevel drive add greatly to the life of the instrument and damps out the noise and vibration.

Another feature of the device is that the distributor arm and brush are radially adjustable, so that practically the whole contact surface can be utilized.

By rotating the distributor casing, the advance and retard positions are obtained. The device can be readily fitted to any Ford by bolting direct on to existing studs:

The patentee is open to negotiate for the manufacture of this invention on a royalty basis, the par-. ticulars of which can be obtained through N. S.

Ba:rlow, Esq., 'patent agent, 16, Bennett's Hill, New Street, Birmingham.

It may cost slightly more to in a n u facture_ than the ordin ary type of coin; mutator, but this would be compensated by its longer life.

142.—Remetalling the Big-ends.

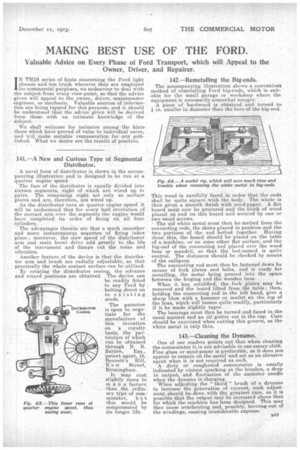

The accompanying illustration shows a convenient method of remetalling Ford big-ends' which sis suitable for the small garage or workshop where the equipment is necessarily somewhat meagre.

• A piece of hardwood is obtained and turned to in. smaller in diameter than the bore of the big-end.

This wood is carefully faced in order that the ends shall be quite square with the body. The whole is then given a smooth finish with sand-paper. A fiat board must now be procured and the block of wood placed on end on this board and secured by one or two wood screws.

The old white metal must then be melted from the connecting rods, the shims placed in position and the two portions of the rod bolted together. Having done this, the board should be placed on the table of a machine, or on some other flat surface, and the big-end of the connecting rod placed over the wood boss or mandril, so that the last-named is quite central. The distances should be checked by means of the callipers. The connecting rod must then be fastened down by means of fork plates and bolts, and is ready for metalling, the metal being poured into the space between the forging and the wooden boss. When it has solidified, the fork plates may be removed and the board lifted from the table ; then, holding the connecting rod in the left hand, give a sharp blow with a hammer or mallet on the top of the boss, which will loosen quite readily, particularly if it be made slightly taper.

The bearings must then be turned and faced in the • usual manner and an oil gutter cut in the cap. Care should be exercised when cutting this groove, as the white metal is only thin.

143.—Cleaning the Dynamo.

One of our readers points out that when cleaning the commutator it is not advisable to use emery cloth. Fine glass or sand-paper is preferable, as it does not appear to remain on the metal and act as an abrasive agent when it is not required as such. A dirty or roughened commutator is usually indicated by violent sparking at the brushes, a drop in output, and fluctuation of the ammeter needle when the dynamo is charging. When adjusting the " third" brush of a dynamo to increase the generation of current, such adjustment should be.done.with the greatest care, as it is possible that the output may be increased above that for which the machine has been designed. This may then cause overheating and, possibly, burning-out of the windings, causing considerable expense.