om Drivers &Mechanics

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Send us an account of any special incident of your work or exfierience. If suitable, we will edit your notes, supply a sketch when required, and pay you for everything published. _Mention your embloyer's name, in confidence, as evidence of good faith. 4cidress to Th.:. Editor, THE COMMERCIAL MOTOR. ROSebery A Veiitte, London, E.C.

Light Up Your Lamps At 4.49 on Thursday ; 4.49 on Friday; 4.49 on Saturday; 4.49 on 3Jonday ; 4.50 on Tuesday ; 4.50 on Wednesday.

A Loading-up Rig.

[1400] " H.B.S." (Cheshire) writes :—" I am sending a tip which will appeal specially to drivers who have to load their own vans.

" When comparatively heavy goods have to be

packed into the body or have to be removed from one end of the machine to the other there is a good deal of hard work attached to the operation. The rig which I have constructed enables a man conveniently to handle goods in such a manner as to make loading up quite easy. I send you a sketch [We have had this redrawn.—En.] which will give an idea. of the arrangement.

" I first of all fitted a length of mild-steel bar, 2 ins. in diameter, to the roof of the body from end to end of the van, fixing it in position by means of two eye bolts placed at each end. I then procured a small mild-steel wheel blank and grooved it to suit the bar. To this runner I attached a set of pulley blocks, and with this outfit I can handle all the heavy loads, which I have to carry, with every convenience."

Testing the Spark-gap of Magnetos.

Tike sender of the following communication h,as been awarded the 108. prize this week.

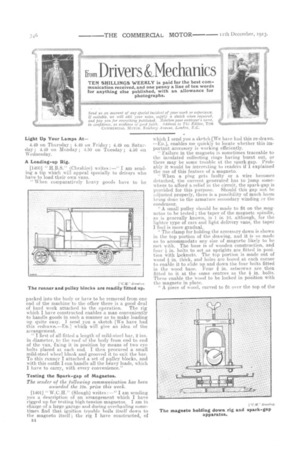

[1401] " W.C.FI." (Slough) writes I am sending you a description of an arrangement which I have rigged up for tenting high-tension magnetos. I am in charge of a large garage and during overhauling sometimes find that ignition trouble boils itself down to the magneto itself ; the rig I have constructed, of

E4 which I send you a sketch [We have had this re-drawn. —En.], enables me quickly to locate whether this important accessory is working efficiently.

"Failure in the magneto is sometimes traceable to the insulated collecting rings having burnt out, or there may be some trouble at the spark-gap. Probably it would be interesting to readers if I explained the use of this feature of a magneto.

" When a plug gets faulty or a wire becomes detached, the current generated has to jump somewhere to afford a relief in the circuit, the spark-gap is provided for this purpose. Should this gap not be adjusted properly, there is a possibility of much harm being done to the armature secondary winding or the condensor.

"A small pulley should be made to fit on the magnetos to be tested ; the taper of the Magneto spindle, as is generally known, is 1 in 10, although, for the lighter type of cars and light delivery vans, the taper I find is more gradual.

" The clamp for holding the accessory down is shown in the top portion of the drawing, and it is so made as to accommodate any size of magneto likely to be met with. The base is of wooden construction, and four in. bolts to act as uprights are fitted in position with Locknuts. The top portion is made out of wood in. thick, and holes are bored at each corner to enable it to slide up and down the four bolts fitted in the wood base. Four in. setscrews are then fitted to it at the same centres as the in. bolts.

These enable the -wood to be locked in position with the magneto in place. "A piece of wood, curved to fit over the top of the

magnets, and a damping down bolt complete this portion of the rig.

" It now remains for me to describe the apparatus for testing the spark gaps.

" A piece of mild steel 6 ins. by 1 in. by 1 in. should be procured and bent at right angles at each end to a depth of 1 in. Obtain a Piece of fibre stick g in. in diameter and out it off to a length which affords a driving fit in the bent metal strip. Four holes, should then be drilled at e-qui-distant points, to accommodate locking screws, for the purpose of fixing four wires the ends of which will form the spark-gap

" The four wires should then be connected up to the terminals of the magneto, which should be ' earthed ' and then set going. The gap between the ends of the wires and the bottom plate can now be adjusted by unscrewing the small locking screws holding the wires until a satisfactory spark is given."

Letter Book-Press for Dismantling Gear Wheels.

[1402] " HAI." (West Bromwich) writes :----" In a recent issue of your journal I notieed, on the D. and pages (letter No. 1374), a particular method_ described for dismantling gears from shafts.

" I am sending a contribution which I consider will show an improvement on the system which • S.F.C.' adopted ; I enclose a sketch [We have had this redrawn.—End, together with the description.

" The device I use is nothing more or less than a second-hand letter-book press, and, when I first saw it in a local store, the thought struck me that it would be just the thing for my purpose. Very little alteration was necessary, which chiefly consisted in increasing the distance between the base and top portion, in order to accommodate comparatively long shafts. To effect this I fitted extra long studs to act as distance pieces, the diameter being 1 in.

" To complete the equipment, I obtained three

pieces of wrought-iron tubing, having an internal diameter of 2 ins., which I considered was quite large enough to take any size shaft likely to come my way. The three pieces of tubing were of different lengths, so that, as the gear wheels were dislodged, a tube of a greater length could be brought into use."

The Double Duties of an Early Paden.

[140:3] H.P."-(Atherton) writes I enclose two photographs of aFoden steam wagon [We reproduce these.—E.] which was delivered to its present owner, I believe, It yeas ago this month. It was reconstructed in 1904, and has been in the employ of a builder's contractor,. which you will agree entails heavy haul-age work of the hardest kind, particularly as most of the material carried is of a sandy nature, which plays havoc with all the bearings. " We carry dressed stone, which is always packed with sand, also rough stone out of the quarries, and, considering that we have to make our way to all classes of building sites, the roads we tackle are sometimes not of the best. Working in the Bolton district, we are only ,-allowed by our firm to carry four tons on the vehicle. Consequently, we have to make up the load on the trailer, which, often enough, carries a weight of five tons.

" The wagon does not get much rest, as you will see from one of the photographs, which shows the engine driving a 10 in. by in, stone crusher. For this purpose, we remove the side and front sheets. We then set the engine up to the crusher, which is fixed on a stone-carrying truck, tbe front wheels of the tractor being pushed right close to the naves of stone-truck so as to prevent vibration as much as possible, and the back wheels of the wagon are then scotched. The drive to the crusher is transmitted by a belt driven Off the engine flywheel.

" I am pleased to say that during close on four years of running I did not lose one journey through breakdown.

" During the busy season of the building trade, we work themachine six days a week ; we wash. out every alternate Sunday.

" The other photograph shows the Foden hauling a general load for a contractor, the load comprising a 30 h.p. gas engine and fittings, whieh weighed just over four tons, and on the trailer is a. quantity of long scaffold poles and steel tramrails, as used on big building sites. The load on the trailer weighed just over five tons, making a total of nine tons.

"We use the best Welsh steam coal, -Nixon's Navigation lam-ps, and this gives entire satisfaction, I can generally run all day without clinkering out, which is a great saving in both time and temper. The boiler wa-s only retubed four years ago.

"Perhaps you will be interested to know that I have fitted a baffle plate in the ashpan similar to the one described in THE COMMERCIAL MOTOR some time ago. [Issue of the 14th August last.—En,]. This device I find to be a great advantage when steaming, as it carries the draught, well into the middle of the fire."