A Free Wheel in a Gearbox

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

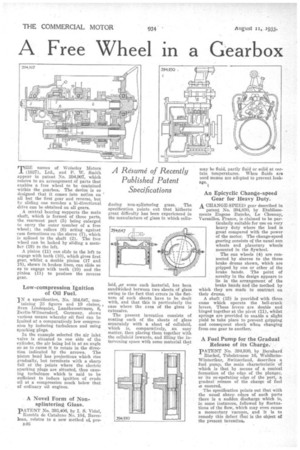

MILE names of Wolseley Motors I_ (1927), Ltd., and R W. Smith appear in patent No. 394,907, which relates to an arrangement of parts that enables a free wheel to be contained within the gearbox. The device is so designed that it comes into action on all but the first gear and reverse, but by sliding one member a hi-directional drive can be obtained on all gears.

A central bearing supports the main shaft, which is formed of three parts, the rearmost part (5) being enlarged to carry the outer member of a free wheel ; the rollers (6) acting against cam formations on the sleeve (7), which is splined to the shaft (2). The free wheel can be locked by sliding a meniber (19) to the left.

A pinion (11) can slide to the left to engage with teeth (10), which gives first gear, whilst a double pinion (17 and 18), shown in broken lines; can slide so as to engage with teeth (10) and the pinion (11) to produce the reverse gear.

Low-compression Ignition of Oil Fuel.

IN a specification, No. 394,647, con taining 23 figures and 19 claims, Sven Lindequist, Landhausstrasse, 8, Berlin-Wilmersdorf, Germany, shows various means whereby oil fuel can be ignited at a comparatively low compression by inducing turbulence and using sparking plugs.

In the example selected the air inlet valve is situated to one side of the cylinder, the air being led in at an angle so as to cause it to rotate in the direction indicated by the arrows. The piston head has projections which rise gradually, but terminate with a sharp fall at the points where the electric sparking plugs are situated, thus causing turbulence which is said to be sufficient to induce ignition of crude oil at a compression much below that of ordinary oil engines.

• A Novel Form of Nonsplintering Glass.

pATENT No. 393,406, by I. S. Vidal, Rambla de Cataluno No. 104, Barcelona, relates to a new method of, pro B46 clueing non-splintering glass. The specification points out that hitherto great difficulty has been experienced in the manufacture of glass in which cellu

bid,ior some such Material, has been sanddiched between two sheets, of glass owing to the fact that errors in the flatness of such sheets have to be dealt with, and that this is particularly the

• case where the erea of the glass is extensive.

The present invention consists of coating each of the sheets of glass separately with a sheet of celluloid, which is, comparatively, an easy matter, then placing them together with the celluloid inwards, and filling the intervening space with some material that may be fluid, partly fluid or solid at certain temperatures. When fluids are used means are adopted to prevent leak age. I

An Epicyclic Change-speed Gear for Heavy Duty.

A CHANGE-SPIEED gear described in

patent No. 394,830, by Etablissements Eugene Dauche, Le Chesney, Versailles, France, is claimed to be particularly suitable for use on very heavy duty where the load is great compared with the power of the motor. The change-speed gearing consists of the usual sun wheels and planetary wheels mounted in the flywheel.

The sun wheels (4) are connected by sleeves to the three brake drums shown, which are gripped by one or other of the brake bands. The point of novelty in the design appears to lie in the arrangement of the brake bands and the method by which they are made to contract on their drums.

A shaft (15) is provided with three cams which operate the bell-crank levers. These levers are double and hinged together at the pivot (11), whilst springs are provided to enable a slight yield to take place to prevent gripping and consequent shock when changing from one gear to another.

A Fuel Pump for the Gradual Release of its Charge.

PATENT No. 394,930, by Bernhard

Bischof, Tobelstrasse 16, WaldhehnWinterthur, Switzerland, describes a fuel pump, the main characteristic of which is that by means of a conical formation of the edge of the plunger, or its co-operating edge of the port, a gradual release of the charge of fuel ts ensured.

• The specification points out that with the usual sharp edges of such parts there is a sudden discharge which is, in some instances, followed by fluctuations of the flow, which may even cause a momentary vacuum, and it is to remedy this defect fhat is the object of the present invention.