Prolonging Engine Life

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

Three New Vokes Devices for Air, Oil and Fuel Purification

A LTHOUGH modern roads are 21,00mparatively free from dust, this objectionable matter is always present in air ; when mixed with oil it becomes a powerful abrasive, harmful to almost every part of an engine. As dust cannot be prevented from blowing about the only course open is to keep it out of the air and oil used in the engine. Interesting new types of filter and cleaner have recentiy been introduced by C. G. Yokes, Ltd. Vokesaeess House, 95-97, Lower Richmond Road, Putney, London, S.W-.15. This company is, of course, responsible for the well-known range of Pnotectomotor filters which are so widely standardized.

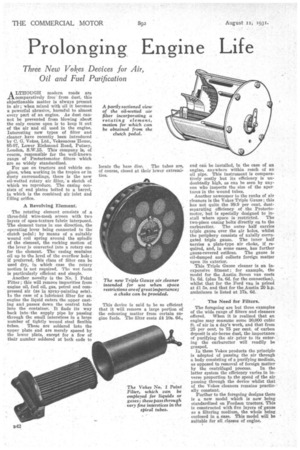

For use on tractors and vehicle engines, when working in the tropics or in dusty surroundings, there is the new oil-wetted rotary air filter, a sketch of which we reproduce. The casing consists of end plates bolted to a barrel, in which is the combined air inlet and filling orifice.

A Revolving Element.

The rotating element consists of a three-fold wire-mesh screen with two layers of open-texture fabric interposed. The element turns in one direction, the operating lever being connected to the clutch pedal; by means of a suitably wound coil spring around the spindle of the element, the rocking motion of the lever is converted into a rotary one for the element. The casing contains oil up to the level of the overflow hole; if preferred, this class of filter can be used dry, in which case the rotary motion is not required. 'The wet form is particularly efficient and simple.

Another novelty is the No. 1 Point Filter ; this will remove impurities from engine oil, fuel oil, gas, petrol and compressed air (as in spray-painting sets). In the case of a lubricant filter for an engine the liquid enters the upper casting and _passes down the central tube into the container. It finds its way back into the supply pipe by passing through the small interstices in a large number of tightly wound steel flexible tubes. These are soldered into the upper plate and are merely spaced by the lower plate, except for a few of their number soldered at both ends to and can be installed, in the case of an engine, anywhere within reach of an oil pipe. This instrument is comparatively costly but its efficiency is undoubtedly high, as can be seen by anyone who inspects the size of the apertures in the wound tubes.

Another newcomer to the ranks of air cleaners is the Yokes Triple Gauze ; this has not quite the 99.9 per cent, dustseparating efficiency of the Protectomotor, but is specially designed to in stall where space is restricted. The two-piece casing bolts directly on to the carburetter. The outer half carries triple gauze over the air holes, whilst the periphery consists of axially corrugated triple gauze. The inner half tarries a plate-type air choke, if required, and, in some cases, has further gauze-covered orifices. The gauze is oil-damped and collects foreign matter upon its exterior.

This Triple Gauze cleaner is an inexpensive fitment ; for example, the model for the Austin seven van costs 7s. 6d. (plus 7s. 6d. for the connection), whilst that for the Ford van is priced at a 5s. and that for the Austin 20 h.p. ambulance is listed at 17s. 6d.

The Need for Filters.

The foregoing are but three examples of the wide range of filters and cleaners offered. When it is realized that an engine may consume some 30,900 cubic ft. of air in a day's work, and that from 25 per cent to 75 per cent. of carbon deposit is air-borne dust, the importance of purifying the air prior to its entering the carburetter will readily be grasped.

In these Yokes products the principle is adopted of passing the air through a body consisting of a purifying medium, as opposed to removal of foreign matter by the centrifugal process. In the latter system the efficiency varies in inverse proportion to the speed of the air passing through the device whilst that of the Yokes cleaners remains practically constant.

Further to the foregoing designs there is a new model which is now being standardized On Fordson tractors. This is constructed with five layers of gauze as a filtering medium the whole being enclosed in a case. This model will be • suitable for all classes of engine.