Drilling Cores from Concrete Roads

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

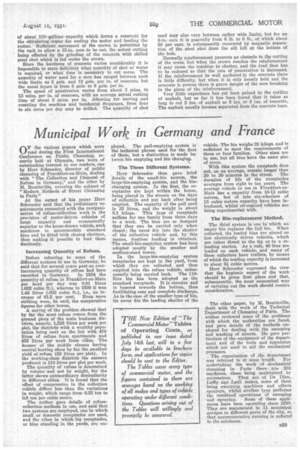

AMACHINE has recently been supplied to_ the Ministry of Transport for use at its research statkan at Harrnondsworth and elsewhere for the purpose of drilling cores from •

concrete roads. It is said to be the first British-made appliance of its kind and was constructed by Messrs. Holman Brothers, of Camborne.

The machine, of which an illustration appears on this page, has been constructed to operate as an independenttrailer unit, the chassis being equipped with Springs and pneumatic tyres. At one end is a stiff vertical frame through which pass two guide rods braced together at the top and bottom by steel forgittgs, and a central rotating hollow shaft or "quill." At the lower end of the quill is fitted a cylinder to the end of which is screwed a " crown" or cutter of ins, external diameter and 61 ins, internal diameter and, initially, about 6 ins. long.

The quill is rotated through reduction gearing which is driven by a belt operated by a Lister ti h.p. engine mounted at the other end. In the centre of the chassis is a tank of about 150 gallons capacity which forms a reservoir for the circulating water for cooling the motor and feeding the cutter. Sufficient movement of the crown is permitted by the rack to allow a 15-in, core to be cut, the actual cutting being effected by the grinding of the concrete with chilled steel shot which is fed under the crown.

Since the hardness of concrete varies considerably it is impossible to state definitely what quantity of shot or water is required, or what time is necessary to cut cores. The quantity of water used for a core has ranged between such wide limits as 3 gals. and 12 gals. per in. of concrete, but the usual figure is from 5 gals. to 8 gals, per in.

The speed of penetration varies from about 2 mins. to 13 mins. per in. of concrete, with an average actual cutting time of about 5 mins. per in. Allowing for moving and resetting the machine and incidental gtoppages, from four to six cores per day may be drilled. The quantity of shot used may also vary between rather wide limits, but for an 8-in. core it is generally from 6 lb. to 8 lb., of which about 50 per centt, is subsequently recovered by magnetic separation of the steel shot from the silt left at the bottom of the hole.

Normally reinforcement presents no obstacle to the cutting of the cores, but when the crown reaches the reinforcement it may cause the machine to chatter, and the load then has to be reduced so that the rate of penetration is decreased. If the reinforcement be well anchored in the concrete there is little difficulty, but when it is only loosely held and the concrete is porous there is grave danger of the core breaking in the plane of the reinforcement Very little experience has yet been gained in the cutting of asphalt, but so far it has been found that it takes as long to cut 2 ins, of asphalt as 6 ins. or 8 ins, of concrete, The asphalt usually became separated from the concrete base.