ROADTEST

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

FODEN SERIES 60

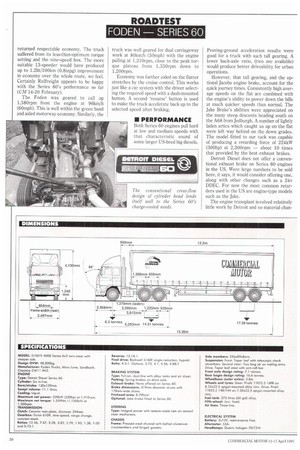

returned respectable economy. The truck suffered from its less-than-optimum torque setting and the nine-speed box. The more suitable 13-speeder would have produced up to 1.21it/100km (0.8mpg) improvement in economy over the whole route, we feel. Certainly Railfreight appears to be happy with the Series 60's performance so far (CM 14-20 February).

The Foden was geared to call up 1,580rpm from the engine at 96kmjh (60mph). This is well within the green band and aided motorway economy. Similarly, the truck was well geared for dual carriageway work at 80km/h (50mph) with the engine pulling at 1,310rpm, close to the peak torque plateau from 1,350rpm down to 1,20Orpm.

Economy was further aided on the flatter stretches by the cruise control. This works just like a car system with the driver selecting the required speed with a dash-mounted button. A second 'resume' button is used to make the truck accelerate back up to the selected speed after braking. Proving-ground acceleration results were good for a truck with such tall gearing. A lower back-axle ratio, (two are available) would produce better driveability for urban operations.

However, that tall gearing, and the optional Jacobs engine brake, account for the quick journey times. Consistently high average speeds on the flat are combined with the engine's ability to power down the hills at much quicker speeds than normal. The Jake Brake's abilities were appreciated on the many steep descents beading south on the A68 from Jedburgh. A number of lightly laden artics which caught us up on the flat were left way behind on the down grades. The model fitted to our tuck was capable of producing a retarding force of 224kW (300hp) at 2,300rpm — about 10 times that provided by the best exhaust brakes.

Detroit Diesel does not offer a conventional exhaust brake on Series 60 engines in the US. Were large numbers to be sold here, it says, it would consider offering one, along with other changes such as a 24v DDEC. For now the most common retarders used in the US are engine-type models such as the Jake.

The engine transplant involved relatively little work by Detroit and no material chart ges to the Foden chassis or cab. Detroit uses standard clutch housings and other major components, so those contemplating their own conversions need not worry about marrying up driveline items such as clutches and gearboxes. The taller of the two Foden cab height settings is, however, necessary for clearance between rocker cover and cab floor.

• CAB COMFORT

The Series 60 has a sound all of its own. From afar the truck whistles a little like a jet turbine winding up. In-cab noise readings show the engine to be louder than some, but the tone is quite acceptable and not at all tiring.

The cable gearlinkage of the Foden simplifies the conversion and requires no rerouting. The throttle pedal has changed, its linkage becoming even simpler than any cable. A demand sensor under the pedal send signals to the DDEC brain via a simple wire. This truly is a drive-by-wire system.

Ride, handling and braking were all as we remember them from previous Foden tractors notably the Cat-powered 4350 twin-steer tested by CM in July 1989. The 4000 Series sleeper cab is arguably the most spacious in the business, it certainly feels that way, and effectively combines comfort with practicality.

The twin-steer Foden's directional stability is especially good it is more surefooted than Foden's tag-axle tractor and better than the average twin-steer too.

We put this down to the Pirelli zero profile tyres fitted by Railfreight, which has paid particular attention to their inflation.

In our experience twin-steers can out-handle every other axle configuration if tyres and load transfer devices are set correctly.

Traction can easily be lost with twin-steers and Foden provides the driver with an air-dump facility which, while working well at the frame, is let down by its switchgear.

The red spring-loaded button sits next to the driver's hip on the engine cover where it cannot be used by a driver already snatching a gear while trying to maintain momentum. The button would be better placed to the right, on the dash, or on the gearlever itself.

The button also lacks a timer switch, so the driver has to hold it down all the time that traction is in doubt, Climbing the long, steep and often slippery timed climbs in our test notably Blackhill which takes over six minutes we were forced to instruct our crewman to keep his hand on the control. Working trucks are not so well staffed.

The other clocks and controls in the Foden work well and the dash is well laid