LESSONS FROM THE WAR.

Page 10

Page 11

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

The Evolution of the Ideal Commercial Motor.

From a Designer's Point of View.

THE WAR, in spite of its many and evident evils, has fortunately produced at least some good. Particularly in the sphere of mechanical engineering such progress has been made during the last three years as would probably not have been equalled in double that period under normal conditions.

The most noteworthy example of this fact is displayed in the enormous advance achieved in the science of aviation, due entirely to the war, which has far exceeded the expectations of most of us. In the case of mechanical transport by road the progress made, though perhaps not so self-evident, is nevertheless considerable. That this should be the case is not surprising when we consider that the daily work of most of the thousands of M.T. vehicles in the service of the fighting armies constitutes nothing Jess than a gigantic reliability trial, which must necessarilyoiscoVer any latent deft of design or construe on n the various types of vehicle employed ; and this in a much more certain manner than would years of use of a, comparatively limited number of vehicles in the ordinary work of commercial haulage on normal roads.

It is, of course well known that the roads on all the fighting fronts are either of a very inferior quality Its compared with our British highways in pre-war days, or have, by reason of much hard use, deteriorated to such an extent as to cause abnormal strains in any vehicles operating upon them for any length of time Speaking generally, it may be said that the standard types of three-ton lorry, as turned out by the principal British and American manufacturers, have shown themselves well-suited to the strenuous work they have been called upon to perform.

Various details, as might be expected, have caused more or less trouble in all types, but these defetts have not generally been of such a nature as to suggest that radical departures from pre-war standards of design are necessary. What seems to be called for is greater simplicity of design, implying the elimination of redundant parts, which are quite numerous in some cases, and greater attention to the perfection of those details which make for ease in handling and adjustment.

It is the purpose of the present article to endeavour to establish some useful general deductions from data. availablerias a result of the enormous growth of mechanical transport for military purposes. We shaIl also point out some of the detail defects which have been brought to light, and offer suggestions as to how the lessons learnt from them may be turned to good account in the production of the ideal commercial vehicle, which we all hope will be within the powers of our designers when conditions happily allow of the wants of our industrial road transport being again freely provided for. The old controversy concerning the different types of final transmission is still carried on with as much enthusiasm as ever, and neither the chain drive nor the various kinds of live axles may be said to have been conclusively proved superior tothe others,despite all that has been said to the contraiy. In the writer's opinion; however, the ideal form of final drive, all things considered, is the worm. geared live axle. This system has been proved at least equal to any other in general efficiency, and it has, moreover, the great inherent advantage of absolutely silent running, coupled with simplicity of construction. This question of silence is one which, however it may appear to individual Users, cannot fail to be of great importance from the point of view of the general public, since the objectionable rattle caused by chain transmission, especially when worn, will be generally admitted to be, to say the least of it, undesirable in these days of refinement in matters mechanical.

The chief advantages claimed for the chain form of drive have always been large ground clearance and minimum unsprung axle weight. On the other hand, no need has lie= proved for a greater road clearance than is afforded by the usual types of live axle when fitted with reasonably large wheels, and, as for the alleged disadvantage of the greater unsprung weight, it need only be said that this has not been found in practice to he of any account whatever.

It is quite easy to exaggerate the importance of the increased central clearance which is afforded by a dead axle, and even this advantage is to a large extent counterbalanced by the presence of relatively large diameter chain rings in close proximity to the wheels which are but a few inches above the road and therefore liable to become clogged with mud on bad roads unless protected by chain cases.

Chain cases, however, are not altogether an unmixed blessing, as is shown in the adjacent diagram 1, seeing that, in the event of the vehicle sinking deeply into a rut, the extremely small clearance at this point is a, distinct drawback.There are also other disadvantages attaching to chain eases, such as the resulting inaccessibility of the chain, which, to gether, have led one maker hitherto specializing in this direction to abandon their use.

On the other hand, the I2 in. clearance under all the parts which is pyovidad in the case of vehicles built in conformity with the W.D. subskly regulations is found_ amply sufficient for all purposes and can only be obtained with a live axle construction.

We may here remark that the various special requirements laid down by the above-mentioned regulations have, in general, been proved to be reasonably suitable to the conditions obtaining in war service, and, although the majority of the vehicles being supplied to the Government are not strictly subsidy models, they embody, in many cases, the main features which characterized this type, i.e., large, diameter driving wheels, standard wheel bushes, interchangeable radiator, live axle, standard steering and control arrangements, four-speed gearbox, with standard ratios 'of gearing, interchangeable bodies, etc.

Returning to the subject of driving axles, we come into contact with another point of design which has, for some time, been the subject of much discussion, and that is the relative merit of transmitting the thrust and torque reaction from a live axle by means • of specially provided torque and radius rod members, separate or combined, as opposed to the alternative of using the forward half of the bearing springs for either or both of these functions.

This question, in the opinion of the writer, is iin• doubtedly settled in favour of the latter arrangement, since it has not only been proved successful by mor, than one maker of repute, but has the additional merit of extreme simplicity, which consideration, although it will always carry the day in the end unless the rival system can show undoubted advantages, seems to be entirely ignored by some designers who, apparently, delight in a multitude of intricate details in the fond hope that they 'add _proportionately to the reliability of their vehicle. The exact opposite is, however, more nearly true, and it can be said that, as a rule, the more parts in any piece of 'mechanism the greater is the trouble which is likely to develop.

The stereotyped argument against the spring drive is that it is not good practice to expect the hearing springs to fulfil successfully the double duty of supporting the load and, at the same time, of transmitting the -drive and torque reaction to the frame. If, however, it has been demonstrated that this not only can be but is actually done, without any visible signs of trouble, surely none, endowed -with an average amount of common sense, can any longer attempt to show that the method is wrong in principle.

Those who persist in this form of argument would presumably be found willing to defend the mental aberration of Sir Isaac Newton who, so the story goes, had a hole cut in. the door of his study so that his favourite eat might go in and out without disturbing her master at his work, but, later on, when she had kittens, made another smaller hole for their use. Turning to the consideration of the power -plant, the normal type of pair-cast four-cylinder engine of about 40 h.p. seems to be most suitable for all the requirements of a three-ton lorry, but experience goes to show the advisability of some method of facilitating starting.

Without, at least, a half-compression device' two men are often needed to crank round on a cold morning and, even so, starting is by no means easy and certain, especially with the sleeve valve type of motor. When we recollect that, in the future, many drivers will be men who are partially disabled, the only alternative seems to he some form of mechanical starter, and, probably, post-war models may be expected to be generally fitted with an electrical starting device. This accessory has, lately, been developed to a satisfactory degree of perfection, and is no longer the "hit and miss'," battery destroying abomination which, until recently, promised to undermine confidence in electrical starters as a practical proposition.

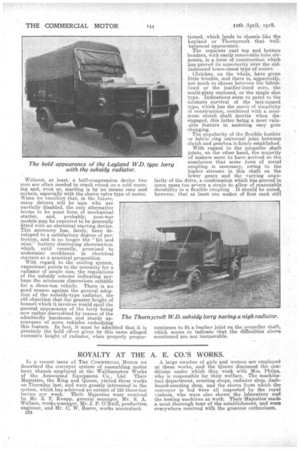

With regard to the cooling system, experience points to the necessity for a radiator of ample size, the regulations of the subsidy scheme indicating perhaps the minimum dimensions, suitable for a three-ton vehicle. There is no good reason against the general adoption of the subsidy-type radiator, the old objection that the greater height of bonnet which it involves would spoil the general appearance of the lorry being now rather discredited by reason of the admittedly handsome and sturdy appearance of some vehicles embodying this feature. In fact, it must be admitted that it is precisely the bold effect given by this same alleged excessive height of radiator, when properly propor

tioned, which lends to chassislike, the Leyland or Thornycroft that wellbalanced appearance.

The separate cast top and, bottom headers, with easily removable tube elements, is a form of construction which has proved its superiority over the oldfashioned brass-eased type of cooler.

Clutches, on the whole, have given little trouble, and there is, apparently, not much to choose between the fabriclined or the leather-lined core, the multi-plate enclosed, or the single disc type. Indications seem to point to the ultimate survival of the last-named type, which has the merit of simplicity • of construction, combined with a minimum clutch shaft inertia when disengaged, this latter being a most. valuable feature in assisting easy gear changing. • The popularity of the flexible leather or fabric ring universal joint between clutch and gearbox is firmly established.

With regard to the propeller shaft joints, on the other hand, the majority of makers seem to have arrived at. the conclusion that some form of metal

lorry coupling is necessary, owing to the

higher stresses in this shaft on the lower gears and the varying angu

larity of the drive, a combination which has proved in some eases too severe a strain to allow of reasonable durability in a flexible coupling. It should be noted, however, that at least one maker of first rank still

continues to fit a leather joint on the propeller shaft, which seems to indicate that the difficulties ahoy° mentioned are not insuperable.