What to Do in Emergencies.

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

During the present state of affairs, we shall substitute this new feature for our usual " Drivers' and Mechanics' Contributions"; these we shall resume when more normal circumstances rule in our industry, We repeat our recent statement, that we are desirous of assisting the "new man at the wheel." of whom there are many at the present time for one reason or another. Our usual D. and M. " pages have included many tips as to workshop procedure, etc. ; some of these we are temporarily dropping, whilst we are selecting more appropriate suggestions

with care. Drivers and mechanics may still send in contributions, which will be paid for at the usual rates.

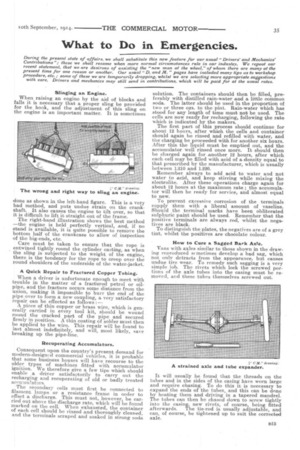

Slinging an Engine.

When raising an engine by the aid of blocks and falls it is necessary that a proper sling be provided for the hook, and the adjustment of this sling on the engine is an important matter. It is sometimes done as shown in the left-hand figure. This is a very bad method, and puts undue strain on the crankshaft. It also causes the engine to tilt over, so that it is difficult to lift it straight out of the frame. The right-hand illustration shows the best method —the engine is held perfectly vertical, and, if no stand is available, it is quite possible to remove the bottom half of the crankcase to allow of inspection of the big-ends, etc.

Care must be taken to ensure that the rope is entwined tightly round the cylinder casting, as when the sling is subjected to the weight of the engine, there is the tendency for the rope to creep over the round shoulders of the underside of the water-jacket.

A Quick Repair to Fractured Copper Tubing.

When a driver is unfortunate enough to meet With trouble in the matter of a fracturd petrol or oilpipe, and the fracture occurs some distance from the union, making it impossible to burr the end of the pipe over to form a new coupling, a very satisfactory repair can be effected as follows A. piece of thin copper or brass wire, which is generally carried in every tool kit, should be wound round the cracked part of the pipe and secured i firmly n position. A thin coating of solder must then be applied to the wire. This repair will be found to last almost indefinitely, and will, most likely, save breaking up the pipe-line.

Recuperating Accumulators.

Consequent upon the country's _present demand for modern-designed commercial vehicles, it is probable that some business houses will have recourse to the older types of machines fitted with accumulator ignition. We therefore give a few tips which should enable a driver satisfactorily to carry out the recharging and recuperating of old or badly treated accumulators.

The secondary cells must first be connected to filament lamps or a resistance frame in order to effect a discharge. This must not, however, be carried out above the discharge rate, which will be found marked on the cell. When exhausted, the container of each cell should be rinsed and thoroughly cleaned, and the terminals scraped and soaked in strong soda solution. The containers should then. be filled, preferably with distilled rain-water and a little common soda. The latter should be used in the proportion of two or three .ozs. to the pint. Rain-water which has stood for any length of time must not be used. The cells are now ready for recharging, following the rate which is indicated by the makers. The first part of this process should continue for about 12 hours, after which the cells and container should again be rinsed and refilled with water, and the charging be proceeded with for another six hours. After this the liquid must be emptied out, and the accumulator well rinsed once more. It should then be charged again for another 12 hours, after which each cell may be filled with acid of a density equal to that prescribed by the manufacturer, which is usually between 1.210 and L220.

Remember always to add acid to water and not water to acid, and keep stirring while mixing the electrolite. After these operations charge again for about 12 hours at the maximum rate ; the accumulator will then be ready for service, and almost equal to new.

To prevent excessive corrosion of the terminals supply them with a liberal amount of vaseline. Should the terminal marks have been obliterated sulphuric paint should be used. Remember that the positive terminals are always red, whilst the negatives are black.

To distinguish the plates, the negatives are of a grey tint, whilst the positives are chocolate colour.

How to Cure a Sagged Bark Axle.

"Vans with axles similar to those shown in the drawing reproduced scmetimes develop a bad sag, which not only detracts from the appearance, but causes undue tire wear. To remedy such sagging is a very simple job. The rivets which lock the screwed portions of the axle tubes into the casing must be removed, and these tubes themselves screwed out.

It will usually be found that the threads on the tubes and in the sides of the casing have worn large and require chasing. To do this it is necessary to expand the ends of the tubes, and this can be done by heating them and driving in a tapered mandrel. The tubes can then be chased down to screw tightly into the casing, new rivets, of course, being fitted afterwards. The tie-rod is usually adjustable, and can, of course, be tightened up to suit the corrected axle.