Number Five. Part One. (Reprinted, for the sake of continuity,

Page 14

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

from pp. 585.-567 in our last volume.) Althotaksh, as a rule, it is well to " Zet well alone,' at needs care 10 ensure that all is always well.

In dealing with the previous articles of the present series it has been our custom to allow a iapse of a considerable interval between the publications dealing with two different types of machine. Owing, however, to the very considerable measure of approval which this series has evoked, we have decided in future to endeavour, so far as the exigencies of Press work will permit, to arrange for further individual articles to follow one another at fairly short intervals.

"Care in the garage reduces cost on the road." so said a prominent user to us the other day, and he is one of those who is not of the class which considers that his sole duty to a first-class commercialvehicle chassis, when once he has purchased it, is to get as much work out of it as possible, an d to " waste " as little time and money as he can upon its care and maintenance.

Neglected Machines which Run Well.

It is really remarkable, in the many instances of which we know, how consistently the majority of the modern industrial machines perform, although in so many cases little attempt is made to take care of the mechanism. Over and over again are instances brought to our notice, in which, in spite of almost entire neglect, motor vans and motor lorries continue to yield remarkable service. Our readers, we feel sure, will not read into that statement an invitation to forgo reasonable precautions, as such consistency of service in spite of neglect is not a characteristic which any maker would care to guarantee, however he may actually feel as to its probability. Therefore, we charge all those who have the care of commercial vehicles in their hands, to treat such carefully-conceived designs with a considerable amount of respect, and to force them selves to realize that, however cleverly the drawing office and the workshops have laboured to produce a machine that shall give the minimum of trouble, it is only possible for that end to be attained if D4

the customer contrive to appreciate at their true worth the many ingenious productions which have been evolved by designers and constructors alike.

Neglect to Employ Means that are Provided.

Writing from the point of view of the actual designer we heartily plead for the more intelligent use of a machine which has, at least, been conceived intelligently. How often are many worried hours of the chief draughtsman, works manager, and other departmental superintendents, rendered ineffective because of the neglect on the part of the eventual owner of the finished product to put to their proper uses the ingeniously-contrived details which are part and parcel of the modern commercial chassis.

"Care of the Chassis " Series.

It is on this account that we publish the present series of articles ; we desire to make clear to those many users who are not additionally engineers, the reason for the individualities of standard chassis. There is no machine built, we imagine, which has not a number of characteristics, about the reason for which any intelligent examiner is inclined at once to inquire. We make it a practice in each of these new articles to explain at some length the scheme upon which it is our desire to base our writing. In this and other instances, we desire that our readers may appreciate our wish to ensure that the means provided for adjustment are employed intelligently, that those components which should be inspected shall, in effect, be examined regularly and at frequent intervals, and, above all, that the detailed means provided for the lubrication both of important and of unimportant parts shall not go neglected on account of ignorance or laxity on the part of the owner and user.

We Examine the Threeton Halley.

The chassis with which we are dealing in this present instance is an example of Halley construction. On the occasion of a recent visit to the Yoker works, we were requested by the directors to concentrate our attention for the present purpose upon the standard 35 h.p. three-ton chassis ; and an excellent one for the purproved to be upon exam 1 Since the 1907 Trials.

The Halley, as an industrial model, may be said to have sprung into notice directly as a result of the success of its representative chassis in the famous Commercial Vehicle Trials organized by the R.A.C. in 1907. Ever since that date its reputation for reliability and steady hard work, on economical lines, has increased and has experienced no set-back. The type of construction has advanced since those days, of course. The models which are built at the present time bear undeniable evidence of the designers' efforts to eliminate unnecessary detail, and, above all, to avoid elaboration.

The machine we examined was, as we have said, one of the 35 h.p. class, and although its design combines every satisfactory means for adjustment with adequate provision for proper inspection, there is an absence of puzzling and unnecessary etcetras.

A Four-cylinder Chain-driven Model.

So far as the general construction is concerned standard lines are more or less followed ; that is . to say, a powerful four-cylinder engine is located in the conventional bonnetted position, and the drive is then transmitted by a big clutch through the universally-jointed propeller shaft into a combined gearbox which houses the change-speed mechanism and the differential gear. The final drive is by chains, encased or open, as the purchaser may choose.

We are not concerned in this series of articles with what is properly described as the "technical description of the chassis," it is our wish only to indicate those details which require either adjustment, inspection or lubrication. Our description of the chassis, therefore, will be incidental to the main purpose. •

Grouping the Components.

We, perhaps, cannot do better than follow the plan which we have adopted in previous articles in this series, namely, that of splitting up the chassis into groups of components, to ensure adequate treatment. We may therefore divide the Halley model as follows :—The engine, with its provision for carburation and fuel supply ; the ignition and cooling accessories ; the clutch and propeller shaft ; the gearbox complete : the chain and chain case ; the brakes, steering gear, wheels, axles and springs.

We will deal with the whole system of lubrication collectively at the latter end of the article, making only incidental reference to details connected with it as we write on chassis adjustment, etc.

The 55 h.p. Engine and its Accessories.

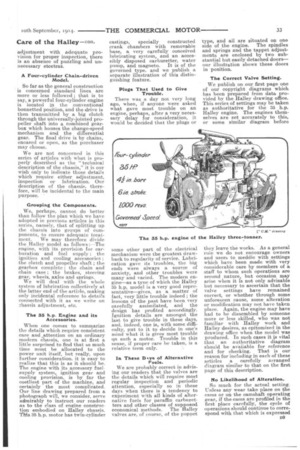

When one comes to summarize the details which require consistent care anclaattention on an ordinary modern chassis, one is at first a little surprised to find that so much time must be allocated to the power unit itself, but really, upon • further consideration, it is easy to realize that this is as it should be. The engine with its .accessory fuelsupply system, ignition gear and cooling provision, is by far the costliest part of the machine, and certainly the most complicated. Our line drawing prepared from a photograph will, we consider, serve admirably to instruct our readers as to the class of engine construction embodied on Halley chassis. This 35 h.p. motor has twin-cylinder

castings, specially constructed crank chambers with removable base, a very carefully conceived lubricating system, and an accessibly disposed carburetter, water pump, and magneto. It is of the governed type, and we publish a separate illustration of this distinguishing feature.

Plugs That Used to Give Trouble.

There was a day not very long ago, when, if anyone were asked what gave most trouble on an engine, perhaps, after a very necessary delay for consideration, it would be decided that the plugs or some other part of the electrical mechanism were the greatest drawback to regularity of service. Lubrication gave its troubles, the big ends were always a source of anxiety, and other troubles were many and varied. The modern engine—as a tyne of which the Halley 35 h.p. model is a very good representative—gives, as a matter of fact, very little trouble indeed ; the lessons of the past have been very carefully assimilated, and the design has profited accordingly. Ignition details are amongst the last to give trouble in these days, and, indeed, one is, with some difficulty, put to it to decide in one's mind what it is gives most trouble on such a motor. Trouble in this sense, if proper care be taken, is a relative term only.

In These DAys of Alternative Fuels.

We are probably correct in advising our readers that the valves are the details which will require most regular inspection and periodic attention, especially so in these days when there is a tendency to experiment with all kinds of alternative fuels for paraffin carburetters and other classes of supposed economical methods. The Halley valves are, of course, of the poppet

type, and all are situated on one side of the engine. The spindles and springs and the tappet adjustments are enclosed by two substantial but easily detached doors— our illustration shows these doors in position.

The Correct Valve Setting.

We publish on our first page one of our copyright diagrams which has been prepared from data provided by the Halley drawing office. This series of settings may be taken as authoritative for the 35 h.p. Halley engine. The engines themselves are set accurately to this, or some similar diagram before

they leave the works. As a general rule we do not encourage owners and users to meddle with settings which have been made with very considerable care by members of a staff to whom such operations are second nature, but occasion may arise when it is not only advisable but necessary to ascertain that the valve settings have remained correct, or whether through some unforeseen cause, some alteration or modification may not have taken place. Again, the engine may have had to be dissembled by someone more or less skilled, who was not familiar with Halley work and Halley desires, as epitomized in the drawing office when the model was produced. In such cases it is vital that an authoritative diagram should be avaiiable for reference and for checking. That is our reason for including in each of these articles a carefully arranged diagram similar to that on the first page of this description.

No Likelihood of Alteration.

So much for the actual setting. Unless any wear take place on the cams or on the camshaft operating gear, if the cams are profiled in the first place carefully, the cycle of operations should continue to correspond with that which is expressed

diagrammatically on our first page. Such wear, however, should not normally take place. Confidence as to that however, should not lead an owner or user of a machine, however good it may be in design, to neglect to ascertain that something of the kind may not have taken place.

The Grinding-in oil Valves.

The valve positions are marked clearly on the flywheel, and the chain of gears operating the camshaft is also relatively marked to facilitate re-erection if dissembled. Alterations, however, take place which are directly traceable to ordinary wear and tear under normal working conditions, and in modern petrol engines, even with the best of fuel, the seats become pitted and occasional grinding-in—a simple enough operation—becomes necessary. This is noticed more particu_ larly on the exhaust valves ; the inlet valves require little more care than occasional inspection.

Adjusting the Tappets.

It is probable that, on a chassis covering normal mileages, the exhaust valves require attention of this kind every 1000 miles or thereabouts. The engine is, as a rule, certain to be the better in respect of its power production, if after such an interval the exhaust valves be rubbed down with fine emery carefully on to their seatings again. Such periodic grinding naturally lowers the valve on its seat, and in course of time the clearance between the valve stern and tappet will thus disappear, and if care be not taken it will be found that when the tappet is released by the cam, this interval having disappeared, the valve will not actually seat, with the result of loss of compression and loss of power to the engine. This is readily remedied by a slight adjustment of the screw tops of the tappets ; these should be lowered from the valve stems, until it is possible to place a thin visiting card between the metal surfaces when the whole of the engine is hot.

The correct clearance between the valve stem and tappet may then be taken as about .007 in.

Users must here be warned that it is never intended that the valves must be set to the aforementioned diagram by means of this tappet adjustment, but rather must the latter be used to accommodate as far as possible variations, from unforeseen cause, from the true setting. When the valves have been ground in sufficiently there may be ridges left round the seats. These should be carefully filed away, and any emery powder used in connection with the grinding-in operation must then be most carefully removed. When the valve plugs are replaced, care must be taken to see that they are screwed down very tightly.

(To be continued.)