The Engineering and Machinery Exhibition.

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

Third Notice.

Drummond Brothers, Ltd., of Guildford. (Stand No. 125.) This enterprising young company has a capital show of its specialities on stand No. 123. Most of the tools made by this .company have been described in "THE COMMERCIAL MOTOR," but its latest product, the 9-inch, self-acting, sliding, surfacing, boring, and screwcutting lathe, is shown for the first time. We had the pleasure of examining this new tool while it was being made (see our issue of the 29th August last), and we are naturally interested to see the first completed machine. There are many special features embodied in its design, and yet, taken in detail, there is nothing new or " freakish " about it. Mr. Arthur Drummond has been guided throughout, in its evolution, by his own and other engineers' experience, and the result is a lathe which should command a big market amongst motor manufacturers, and large repair depots. Our full. description is made after careful examination at Olympia.

There is no over-hang of the saddle when worked over the gap-space of the bed, which disposition allows pieces as large as 30 inches in diameter to be turned. The design of the bed may be better understood by a reference to the issue of this journal to which we have already referred, and by an examination of our illustration on page 137. The slides, on which the saddle is guided, are formed at the level of the bottom of the gap, and extend right along the gap-space, instead of being formed at the top level, and stopping short at the gap. A much larger wearing surface is also secured by this shape of bed.

The head-stock has 14 speeds, in practically geometrical progression ;

two of these are open, belt speeds, and twelve through a choice of back-gears. The gears in the head-stock are enclosed in an oil-bath, and, when the lathe is running, it is working precisely like an ordinary, back-geared lathe, and there are no idle pinions running, or any other ''o-ears except those actually required for the desired speed. The change-gear box for screw-cutting and feeding, by means of which 41 threads or feeds are available without changing a single gear-wheel, is also fitted with an arrangement enabling the lathe to be set up for cutting metric, or any unusual threads.

The cross-slide of the compound rest is well provided with inverted T slots, on which irregular work may be bolted or clamped for the operations of boring, milling, or surfacing. On this ample surface, twin-cylinder castings may be bared with the greatest accuracy. The table has a self-acting cross-feed, as well as longitudinal-feed, but either of the self-acting feeds may he thrown out of gear at the will of the operator. The object of the designer has been to give a slide of the widest possible usefulness, and it is a great improvement on anything we have previously seen.

Very heavy work may be done on this machine, which has a 9-foot bed. In running down a bar, two tools may be brought into use ; one is a reverse tool on the off-side for roughing out, and another tool in the slide-rest for a second or finishing cut, these two tools being at work simultaneously. The apron is double throughout, and each wheel in it is carried between two bearings.

This lathe has embodied in its construction the latest developments in lathe design. The countershaft has no gears, gate changes, or other speedchanging devices; it is simply a countershaft running in swivelling, selfoiling, bearings, and carrying two friction pulleys, and one fixed pulley for the head-stock. As the machine reverses in the apron, reversing in the countershaft is not necessary. The two friction pulleys are intended to run at too and 200 revolutions per minute respectively, both in the same direction. It is an ideal tool for any machine shop of somewhat limited size, and, even for the large manufacturer, such a tool would be found very useful,

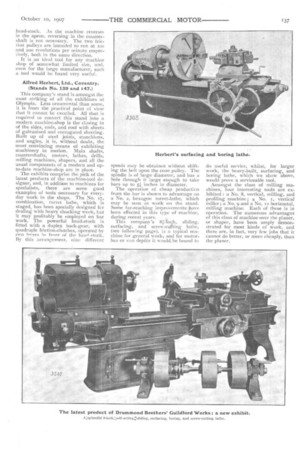

Alfred Herbert, Ltd., Coventry. (Stands No. 139 and 147.) This company's stand is amongst the most striking of all the exhibitors at Olympia. Less ornamental than some, it is from the practical point of view that it cannot be excelled. All that is required lo convert this stand into a modern machine-shop is the closing in of the sides, ends, and roof with sheets of galvanised and corrugated sheeting. Built up of steel joists, stanchions, and angles, it is, without doubt, the most convincing means of exhibiting machinery in motion. Main shafts, countershafts, motors, lathes, drills, milling machines, shapers, and all the usual components of a modern and upto-date machine-shop are in place.

The exhibits comprise the pick of the latest products of the machine-tool designer, and, in addition to machines for specialists, there are some good examples of tools necessary for everyday work in the shops. The No. 17, combination, turret lathe, which is staged, has been specially designed fcr dealing with heavy chucking work, but it may profitably be employed on bar work. The powerful head-stock is fitted with a duplex back-gear, with quadruple friction-clutches, operated by two 1P,ers in front of the hea,1 -crock. By this arrangement, nine different speeds may be obtained without shifting the belt upon the cone pulley. The spindle is of large diameter, and has a hole through it large enough to take bars up to 5.'j inches in diameter. The operation of cheap production from the bar is shown to advantage on a No. 2, hexagon turret-lathe, which may be seen at work on the stand. Some far-reaching improvements have been effected in this type of machine, during recent years. This company's 8I-r-nh, surfacing, and screw-cutting lathe, (see following page), is a typical machine for general worko. and for motorbus or van depots it would, be bound to

do useful service, whilst, for larger work, the heavy-built, surfacing, and boring lathe, which we show above, would prove a serviceable tool.

Amongst the class of milling machines, four interesting tools are exhibited : a No. 8, vertical, milling, and profiling machine; a No. t, vertical miller; a No. 9 and a No, T2 horizontal, milling machine. Each of these is in operation. The numerous advantages of this class of machine over the planer, or shaper, have been amply demonstrated for most kinds of work, and there are, in fact, very few jobs that it cannot do better, or more cheaply, than the planer.