BODY CONSTRUCTION

Page 54

Page 55

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

and STYLE REVIEWED

The Trend of Developments as Exemplified by the Commercial Motor Show. The Tendency Towards Lighter Structures

TILE minimization of weight for both goods and passenger bodywork seems to be the general trend. On every band one sees examples of all-metal construction, light channel-sectioned members being utilized in place of heavy wood lougitudinals or cross-bearers.

Whilst many features of construction are, of necessity, entirely hidden from view, the design of bodies generally makes it clear that designers have really " got down" to new styles and new forms of detail construction. Light alloys in cast and extruded form are in evidence, whilst sheet-metal sections, pressings, etc., are to be seen on all classes of bodywork.

Quite a new note is struck by a Harrington hotly (Stand 90) mounted

on a Leyland Tiger TSG chassis. The vehicle in question is a 33-seater observation saloon. A futuristic effect is created by utilizing sloping window pillars and by employing panelled sides picked out in two shades of blue and a grey lower panel, the aft end of which is curved downwards in streamlined fashion. This form of construction enables really large luggage accommodation to be obtained ; beneath the rear seats is a capacious locker which, together with lockers along the sides. gives a capacity of 80 cubic ft.

Staircase Design.

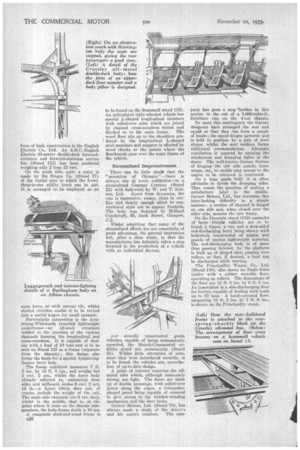

For peak loads in large towns, the rear entrance and single staircase of double-deck buses have often been considered inadequate for really rapid loading and unloading. To meet this contingency, Guy Motors, Ltd. (Stand 74), shows a 4,S-seater double-decker (with a body by Charles H. Roe (1923), Ltd.), with a central double staircase, entrance being effected through double doors,

which are arranged to lock in either the open or closed positions.

In the upper saloon a central gangway gives access to double seats, except near the staircase, where they are separate. By careful design, the amount of waste space has been reduced to a minimum; a special benefit of the system is that the conductor is able to reach all fare-paying passengers with the least possible trouble. Side seats are satisfactorily arranged over the wheel-arches in the lower saloon.

Another design of central entrance with a single wide staircase is to be found on the new Gloster four-wheeled trolley-bus (Stand 120). The frame is dropped to give a loading height no greater than 12 ins. On the opposite side of the chassis is the emergency lighting equipment, a 400-volt motor being coupled to a 12-volt dynamo in the usual way.

An interesting Point concerning the

control gear is that the front body panels can be readily removed to gain access to the main contactors, or, if necessary, the controller. Again, the main resistances arc fitted between the chassis frame members at the forward end of the vehicle, where there are, of course, louvres fitted in the front panelling. It is difficult to give a double-decker a striking appearance without having to resort to bizarre colour schemes. Short Brothers (Rochester and Bedford), Ltd. (Stand 127), seems to have the knack of giving a few deft touches here and there which have the effect of

obtaining the individuality so often desired.

The double-deck coach, built on an A.E.C. Renown chassis, is a case in point. The moulded waist rail, with a gold line beneath it, is curved upwards slightly at the forward end and, in conjunction with a return given to the bottom of the lower panels, lends a modern touch, which is enhanced by the sloping V-front of the upper deck and the rear panel.

A wide sliding door gives access to a forward staircase—wider than those usually found in service buses. This staircase communicates with an off-side gangway, the seats on the near side accommodating three passengers abreast.

An interesting point concerning the construction of this body is that concealed ventilators are built into the standing and window pillars. Air is drawn through a hollow cant-roil by suction generated by specially shaped louvres formed in the external panelling of the pillars themselves.

Good Alt-metal Examples.

Two of the best examples of all-metal construction are to be found on the Crossley and Burlingham stands. Both bodies are built much on the same lines.

The Crossley body (Stand 68) is a sturdy structure, despite its light weight. It is built up largely of I, T and L-sectioned members, most of which are castings, although the longer components have been extruded. The reinforcement of the various beams and pillars by steel plates, which are through-riveted on to the webs, of all heavily loaded components, is au interesting feature.

A cellular formation is adopted for both upper and lower saloons, several equally spaced frames being utilized, in addition to the forward bulkhead and the aft panel. It is interesting to note that the forward bulkhead main pillars have been built up of steel plates, developed into a box section and shaped so as to conform with the curve of the body sides. Thus, the heavy inertia load imposed by a sudden application of the brakes, when the upper deck is full, is taken care of.

The Burlingham body (Stand 125) is constructed in cells, which virtually form the sides and, of course, the rear of the lastly itself. Each cell is made up of a casting in a special silicon alloy of high-tensile strength, with extruded metal sections to form the cant-rails, waist-rails, etc. These are welded to the main castings (forming the pillars), the whole being enclosed by panels rolled from aluminium manganese alloy—a material which is strpnger than ordinary aluminium.

To finish off, headings are used at all joints, and, in order to facilitate assembly and prevent actual metal-tometal contact, fillets of hardwood are interposed between the standing pillars of adjacent frames. The whole is then clamped together by bolts in the usual way. At the point of attachment to the frame, steel flitches are used to ensure adequate support ; even so, the weight of the 52-seater body, as exhibited, is but 2 tons 7 cwt.

Low-height Double-deckers.

In certain localities, where low bridges are encountered, it becomes essential to produce lower double-deck bodywork than is necessary in ordina,ry circumstances. A ease in point is a fonr-wheeled 48-50-seater double-deck trolley-bus, produced by the Sunbeam Motor Car Co., Ltd. (Stand 16), with bodywork by Park Royal CoachwOrks, Ltd.

By sinking the off-side upper gangway, a matter of 10 ins., legal headroom is maintained on both upper and lower decks, yet the overall height of the vehicle over the trolley base is but 13 ft. 8i ins. Where clearances arc fine, a matter of inches of height saved is most important The body hoops carrying the trolley base are separate from the normal domed roof, and, whilst they ensure adequate strength, the overall height of the ensemble is accordingly reduced by 1! in.

Leyland bodywork (Stand 63) is built up of steel frames with rolled sections suitably shaped and spot welded together to obtain the necessary strength. The floor is composed of tongued and grooved boards on cross-bearers made from flange-sectioned steel.

To these cross-bearers the side pillars are fixed by means of steel gussets, suitable angle-section bars being fitted for the full length of the body (except, of course, in proximity of the wheel-arches). The longitudinal rails are built up of channel-sectioned steel and are secured to the pillars by bolts which pass through tubes inserted in the pillars before the hollow sections are welded together. Each side pillar, by the way, carries blocks of fibre to form a fixing to the panelling—a light but immensely strong method of construction.

Composite Bodies.

Amongst manufacturing concerns which remain faithful to the composite form of body construction is the English Electric Co., Ltd. An A.E.C.-English Electric 63-seater double-deck forwardentrance and forward-staircase service bus (Stand 113) has been produced weighing only 2 tons 12 ewL On the goods side, quite a point is made by the Singer Co. (Stand 77) of the varied uses to which the 5-cwt. three-in-one utility truck can be put. It is arranged to be employed as an open lorry, or with canvas tilt, whilst slatted creches enable it to be turned into a useful wagon for small animals.

Particularly interesting is the Armstrong-Whitworth Ironclad lightweight underf rame —an all-steel structure welded at the junction of the various channels forming the longitudinal and cross-members. It is capable of dealing with a load of 10 tons and is to be seen on Stand 122 as a frame (separate from the chassis) ; this design also forms the basis for a special ArmstrongSaurer lorry body.

, The frame exhibited measures 7 ft. 3 ins. by 12 ft. 6 ins., and weighs hut 2 cwt. 3 qrs., whilst the lorry body already referred to embracing drop aides and tailboard, scales 9 cwt. 2 qrs. 14 lb.—a figure which does not, of course, include the weight of the cab. The main side channels are 6 ins. deep, whilst in the middle, that is, at the point where it rests on the chassis sidemembers, the body-frame depth is 10 ins.

A composite steel-and-wood frame is c26 to be found on the Scammell stand (15). An articulated eight-wheeled vehicle has special L-shaped longitudinal members with rolled-over sides which are joined by channel cross-members bolted and flitched on to the main frame. The wood floor sits on to the shoulders produced by the longitudinal L-shaped steel members and support is effected by wood chocks at the points where the floorboards pass over the main frame of the vehicle.

Streamlined Impressiveness.

There can be little doubt that the " sensation of Olympia "—there is always one at every exhibition—is a streamlined Commer Centaur (Stand 22) with bodywork by W. and 'T.Robson; Ltd. Apart from dynamics, the van is impressive, roomy, clean in outline and closely enough allied to conventional style not to appear freakish. The body was designed by Holland Coachcraft, 95, Bath Street, Glasgow, C.2.

Whilst admitting that many of the streamlined effects are not essentially of great advantage, the general impression left, after a close stUdy, is that the manufacturer has definitely taken a step forward in the production of a vehicle with an individual flavour.

r or soundly constructed goods vehicles, capable of being economically operated, the Morris-Commercial exhibits stand out prominently (Stand 21). Whilst little alteration of note, since they were introduced recently, is to be found, the vehicles are, nevertheless, of up-to-date design.

A point of interest concerns the allmetal cabs which, although immensely strong, are light. The doors are made up of double pressings, with rolled-over joints along the edges, a triangularshaped panel being capable of removal to give access to the window-winding mechanism and the door locks.

Garner Motors, Ltd. (Stand 78), has always made a study of the driver's and his mate's comfort. The corn

patty has gone a step 'farther in this matter in the cab of a 1,000-cubic-ft. furniture van on the 4-ton chassis.

To meet this contingency the Garner designers have arranged the seat and squab so that they can form a couple of bunks ; the squab hinges upwards and is held in position by a pair of steel straps, whilst the seat cushion forms additional accommodation. Adequate ventilation is assured by opening the windscreen and dropping lights in the doors. The well-known Garner feature of hinging the cab side panels, front wings, etc., to enable easy access to the engine to be obtained is continued.

On a long goods body it is often advisable to divide the dropping sides. Then comes the question of making a satisfactory joint in the middle. Garner Motors, Ltd., has overcome this inter-locking difficulty in a simple manner ; a section of channel is hinged on one side and, when closed over the other side, secures the two firmly.

On the Duramin stand (112) examples of large freight -vehicles are to be found, a tipper, a van and a deep-sided end-discharging lorry being shown with bodywork constructed of angles and panels of special lightweight material. The end-discharging body is of more than passing interest, for the platform is built up of hinged slats passing over rollers, so that, if desired, a load can be discharged while moving.

The Principality Wagon Co., Ltd. (Stand 110), also shows an Eagle 6-ton trailer with a rubber movable floor, operating on rollers. The dimensions of the floor are 13 ft. 8 ins. by 6 ft. 6 ins. An innovation is a side-discharging floor for lorries, capable of dealing with loads up to 12 tons.. A hand-operated floor, measuring 12 ft. 2 ins. by 7 ft. 6 ins., is shown on the Principality stand.