SIMPLE

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

Carburation, 4

In the last article (March 29) the constant vacuum, variable choke type of carburettor was discussed. Now the other type, the fixed venturi variable depression kind, will be considered.

The "'simplecarburettor discussed in an earlier article

suffers from the inherent fault of providing a progressively richer mixture as the speed of the en gine increases. The compound jet system illustrated diagrammatically in Fig 1 is a popular

method of -correcting" mixture strength so that this does not occur.

In addition to the main jet of the simple carburettor another quite separate jet is situated alongside the main jet. This second jet acts as a cornpensa tor to the main jet, supplying a weak mixture when engine speed is high and the main jet is providing too rich a mixture.

Fuel is suppliedto the compensating jet by a well which is

open to the atmosphere. This well is supplied by fuel through the compensating jet from the float chamber.

When the mixture from the main jet enriches as engine speed increases, that supplied by the compensating jet weakens because the level in the well falls and only the fuel which can'flow through the compensating jet is available.

At low speeds the compensating jet provides ample fuel but the main jet gives a reduced supply because of the lower air speed in the venturi; the two jets, therefore, tend to supply a

uniformly proportioned mixture. A further correction system is the "air bleedmethod where

fuel and air supply are controlled by immersed air bleeds.

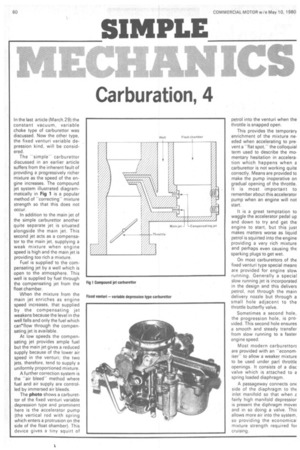

The photo shows a carburettor of the fixed venturi variable depression type and prominent here is the accelerator pump (the vertical rod with spring which enters a protrusion on the side of the float chamber). This device gives a tiny squirt of petrol into the venturi when the throttle is snapped open.

This provides the temporary enrichment of the mixture needed when accelerating to prevent a "flat spot," the colloquial term used to describe the momentary hesitation in acceleration which happens when a carburettor is not working quite correctly. Means are provided to make the pump inoperative on gradual opening of the throttle. It is most important to remember about this accelerator pump when an engine will not start.

It is a great temptation to waggle the accelerator pedal up and down to try and get the engine to start, but this just makes matters worse as liquid petrol is squirted into the engine providing a very rich mixture and perhaps even causing the sparking plugs to get wet.

On most carburettors of the fixed venturi type special means are provided for engine slow running. Generally a special slow running jet is incorporated in the design and this delivers petrol, not through the main delivery nozzle but through a small hole adjacent to the throttle butterfly valve.

Sometimes a second hole, the progression hole, is pro• vided. This second hole ensures a smooth and steady transfer from slow running to a faster engine speed.

Most modern carburettors are provided with an -economiser" to allow a weaker mixture to be used under part throttle openings. It consists of a disc valve which is attached to a spring loaded diaphragm.

A passageway connects onE side of the diaphragm to thE inlet manifold so that when E fairly high manifold depressior is present the diphragm moveE and in so doing a valve. This allows more air into the system, so providing the economica mixture strength required foi cruising.