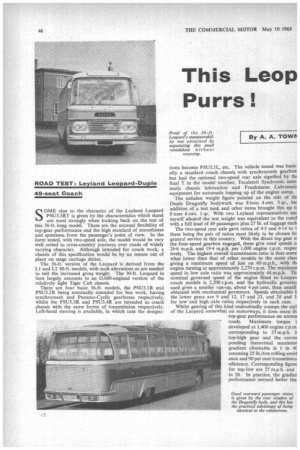

This Leop Purrs !

Page 48

Page 49

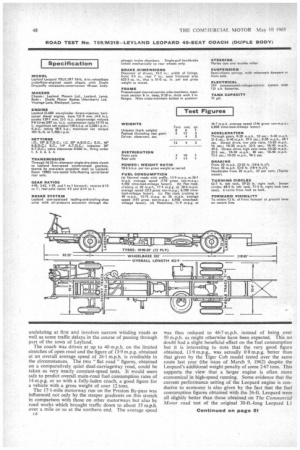

Page 50

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

By A. A. TOWIN Fch.E. ROAD TEST: Leyland Leopard-Duple 49-seat Coach SOME clue to the character of the Leyland Leopard PSU3.3RT is given by the characteristics which stand out most strongly when looking back on the test of this 36-ft.-long model. These are the unusual flexibility of top-gear performance and the high standard of smoothness and quietness from the passenger's point of view. In the form tested, with two-speed axle, the model would be very well suited to cross-country journeys over roads of widely varying character. Although intended for coach work, a chassis of this specification would be by no means out of place on stage carriage duties.

The 36-ft. version of the Leopard is derived from the LI and L2 30-ft. models, with such alterations as are needed to suit the increased gross weight. The 30-ft. Leopard in turn largely amounts to an 0.600-engined version of the relatively light Tiger Cub chassis.

There are four basic 36-ft. models, the PSU3.1R and PSU3.2R being nominally intended for bus work, having synchromesh and Pneumo-Cyclic gearboxes respectively, whilst the PSU3.3R and PSU3.4R are intended as coach chassis with the same forms of transmission respectively. Left-hand steering is available, in which case the designa tions become PSU3.1L, etc. The vehicle tested was basic. ally a standard coach chassis with synchromesh gearbox but had the optional two-speed rear axle signified by thc final T in the model number, Tecalemit Syndromic auto. matic chassis lubrication and Frankmann Lubrimatic equipment for automatic topping up of the engine sump. The unladen weight figure painted on the side of tilt Duple Dragonfly bodywork was 8 tons 4 cwt. 3 qr., bu addition of a test tank and other items brought this up tc 8 tons 6 cwt. 1 qr. With two Leyland representatives an myself aboard the test weight was equivalent to the coact with a full load of 49 passengers plus 27 lb. of luggage each The two-speed rear axle gave ratios of 45 and 6.14 to 1 these being the pair of ratios most likely to be chosen fo general service in this country. With the direct top gear o the four-speed gearbox engaged, these give road speeds o 26.6 m.p.h. and 19.4 m.p.h. per 1,000 engine r.p.m. respec tively. The highest overall transmission ratio is thus some what lower than that of other models in the same class giving a maximum speed of just on 60 m.p.h., with thi engine turning at approximately 2,270 r.p.m. The rnaximun speed in low axle ratio was approximately 44 m.p.h. Thi nominal governed speed of the engine fitted to Leopan coach models is 2,200 r.p.m. and the hydraulic govern° used gives a smaller run-up, about 4 per cent, than usuall: obtained with mechanical governors. Speeds obtainable it the lower gears are 9 and 12, 17 and 23, and 28 and 3. for low and high axle ratios respectively in each case.

Whilst gearing of this kind undoubtedly cramps the styl. of the Leopard somewhat on motorways, it does assist th top-gear performance on nbrma roads. Maximum torque i developed at 1,400 engine r.p.m. corresponding to 37 m.p.h. ii top-high gear and the corres ponding theoretical maximun gradient climbable is 1 in 4C assuming 25 lb./ton rolling resist ance and 90 per cent transmissioi efficiency. Corresponding figure for top-low are 27 m.p.h. and in 26. In practice, the gradier performance seemed better tha might be suggested by this. The vehicle had covered over 4,000 miles on demonstration work at the time of the test, sufficient to have become nicely run-in. However, the favourable impression of the vehicle's performance was undoubtedly heightened by the smooth way in which it was produced. The amount of engine vibration transmitted to the interior of the coach was exceptionally small—less, I would say, than on any dieselengined vehicle I have travelled in. The nature of the engine noise could be recognized as that of a diesel but seemed quite remote—it was never necessary to raise one's voice in conversation even at full throttle or high speeds, when the fan made the most prominent sound.

The Leopard's idling was also quiet by diesel standards, completely regular and surge-free and it was impossible to detect any vibration by touching the panelling when standing in the roadway at the rear of the coach—a standard very rarely reached on a diesel vehicle.

The credit for this degree of refinement must be shared between the 0.600 engine as a unit, which seems generally agreed to be the sweetest-running engine in the current Leyland range, the C.A.V. NN injection pump and hydraulic governor, the link-type engine mounting which incorporates a hydraulic damper, and some sound-deadening material in the floor of the Duple bodywork. From a passenger-comfort point of view this is perhaps the Leopard's strongest merit.

Another factor which may have a bearing on this subject is the somewhat surprising fact that the Leopard coach version of the 0.600 is a de-rated unit. Although its maximum output of 130 b.h.p. is slightly greater than the 125 b.h.p., which has been the normal maximum output for passenger versions of this engine until the past year or two, this is a consequence of the increase in governed speed from the old figure of 1,800 r.p.m. The maximum torque, 405 lb.-ft., represents a slight drop from the earlier figure of 410 lb.-ft. produced by this engine.

The direct-drive acceleration figures, even with the low axle ratio in use, appear on paper to be of no more than average standard. What must be borne in mind, however, is that maximum acceleration can be used freely without any sensation of over-stressing the engine or discomfort to the passengers. In practice, a normal large main-road roundabout could be negotiated in top-low gear, with adequate if not exciting subsequent acceleration. Using direct drive and the high axle ratio, acceleration was naturally slow but roughness was only apparent below 12 m.p.h. (450 engine r.p.m.), making this ratio quite usable when not in a hurry down to say 17 m.p.h.

Experimental runs prior to my arrival had, I was told, shown that the best standing-start acceleration figures were obtained by starting in second gear with the low axle ratio engaged, changing up into third and then top retaining "low ", and finally into high axle ratio. This method was accordingly used for the recorded figures and generally also in normal driving, whenever starting from rest. The ratios of the two-speed axle " split " those of the gearbox more effectively than is often found, however, and frequent use of the control switch was made in traffic or on hills. Coupled with the flexibility of the engine performance this added materially to the ease of driving, since quite a wide speed range could be covered with no more than a touch of the switch and a dab of the clutch pedal.

The "normal roads " fuel consumption figure in the data panel was taken over the route from Euxton to the Langton By-pass normally used in this journal's road tests of Leyland models. Although flat in the later sections, it is heavily undulating at first and involves narrow winding roads as well as some traffic delays in the course of passing through part of the town of Leyland.

The coach was driven at up to 40 m.p.h. on the limited stretches of open road and the figure of 13-9 m.p.g. obtained at an overall average speed of 26.1 m.p.h. is creditable in the circumstances. The two "flat road" figures, obtained on a comparatively quiet dual-carriageway road, could be taken as very nearly constant-speed tests. It would seem safe to predict overall main-road fuel consumption rates of 14 m.p.g. or so with a fully-laden coach, a good figure for a vehicle with a gross weight of over 12 tons.

The 17-1-mile motorway run on the Preston By-pass was influenced not only by the steeper gradients on this stretch in comparison with those on other motorways but also by road works which brought traffic down to about 35 m.p.h. over a mile or so at the northern end. The average speed c4

was thus reduced to 46-7 m.p.h. instead of being over 50 m.p.h. as might otherwise have been expected. This no doubt had a slight beneficial effect on the fuel consumption but it is interesting to note that the very good figure obtained, 11-9 m.p.g., was actually 0-8 m.p.g. better than that given by the Tiger Cub model tested over the same route last year (the issue of March 9, 1962) despite the Leopard's additional weight penalty of some 2.67 tons. This supports the view that a larger engine is often more economical in high-speed running. Some evidence that the current performance setting of the Leopard engine is conducive to economy is also given by the fact that the fuel consumption figures obtained with the 36-ft. Leopard were all slightly better than those obtained on The Commercial Motor road test of the original 30-ft.-long Leopard LI

with similar transmission ratios running at a gross weight of 11 tons, reported in the issue of December 25, 1959.

The climb of Parbold Hill (0-75 mile at an average gradient of 1 in 12) was made in 2 min. 44 sec., 1 sec. faster than the Tiger Cub and 27 sec. faster than the Leopard referred to in the last paragraph. The combination of the two-speed axle and 2,200 r.p.m. governed speed of the engine assisted in achieving this remarkably good performance. Much of the climb was made at 23 m.p.h., peak revs in second-high, and an almost instantaneous change to second-low enabled the speed to be kept up over the 1 in 6-5 section and for the 30 sec. during which this ratio was required.

A Tapley performance meter recorded a maximum pull of 180 lb./ton in second-high during the Leopard's climb, which agrees very closely with a calculated figure of 178 lb./ton based on 85 per cent transmission efficiency in

an indirect gear and 25 lb./ton rolling resistance. This corresponds to the ability to climb a I in 12.4 gradient. The vehicle's coolant thermometer recorded 180°F. (82°C.) at the top of the hill, the normal running temperature being in. the region of 170°F. (77°C.), whilst the ambient temperature was 10°C. (50°F.). An easy restart on the 1 in 6.5 gradient was subsequently made in first-high.

The brakes of the Leopard are virtually unaltered from those of the Tiger Cub, but as the latter derived much of their design in turn from a heavier model, plenty of reserve braking power remains. In practice, the smoothly-graded response to moderate pedal pressures inspired confidence during normal driving. The tests of minimum stopping distances supported this impression, giving better results than those of the Tiger Cub, the greater weight evidently serving merely to hold the wheels down more firmly. Tapley meter readings during these tests were between 80 and 85 per cent. A slight tendency to pull to the right was noted but this was not in any sense dangerous.

The handbrake performance rather depended on the muscle power of the driver and although it held the vehicle unaided facing both up and down a 1 in 6.5 slope it seems clear that the limit of the present system's capabilities is being approached on a 12-ton gross vehicle. The lever is not ideally placed for application of the maximum pull and a greater leverage ratio would be preferable, I feel.

Good Fade Resistance With a single-circuit air-pressure system the Leopard is open to criticism because of the possible consequences in the unlikely event of a sudden loss of pressure, but in practice resistance to fade is likely to be of more regular importance in normal operation of a well-maintained vehicle. In this respect the Leopard showed up well. The bodywork of the test vehicle allowed little ventilation of the rear brakes in particular because of the close shrouding of the wheels. A smell of hot linings became evident after about two-thirds of the descent of Parbold Hill in neutral, using the brakes to keep the speed down to a steady 20 m.p.h. A gauge fitted by the Leyland experimental department recording the line pressure to the brake chambers showed very little increase in the pressure required during the descent and a full brake application at the foot of the bill, with no pause for recovery, gave a Tapley meter reading of 61 per cent. Part of the road had been relaid at this point and marks on the road suggested that some locking of the nearside front wheel on the tarred surface had occurred.

Although the standard of ride reached the usual good standard expected of an underfloor-engined model, it seemed marginally firmer than on some other recent coaches. Little roll was evident when cornering despite a high floor level.

Very little basic alteration appeared to have been made to the steering in producing the 36-ft. Leopard as compared with the 30-ft. models from which it was derived. A greater lock angle has been obtained, as the wheel turning circles are actually slightly less, but six turns of the steering wheel continue to be required to go from one lock to the other. Not unnaturally, a little of the lightness of the small models' steering appeared to have been lost. Oddly enough, this seemed less evident when cornering or in slow speed manoeuvring than on straight roads and I have the impres sion that there may have been a trace of mechanical tightness in the steering box of the test vehicle, either due to slight maladjustment or lingering newness. As things stood, the castor action was barely sufficient for the vehicle to maintain a straight course without occasional slight correction although the steering would self-centre to a nicely-judged degree after cornering. Virtually no reaction

could be felt when traversing poor surfaces.

The swept turning circle on left lock was, as measured, 4 in. over the legal maximum in this country. This was clearly a matter of adjustment since numerons Leopard PSU3 models have passed official tests of this feature. It is worth remarking, however, that the sidelarnps, forming part of the moulding over the front grille on the Duple Dragonfly body, would have eliminated this excess if mounted elsewhere, quite apart from appearing very vulnerable in their present position.

The driving position is of the comparatively upright form usual on underfloor-engined models, giving a good sense of control. The steering wheel feels large not only because of its 22-in, diameter but also because of its massive circularsection rim. I would have preferred a slightly slimmer rim, although I admit this is largely a matter of taste and that the finger grips on the underside are well-designed. The pedals are well placed and of shape and movement which make them comfortable to operate, the Leyland organpedal accelerator being, I feel, one of the best of its kind.

The gear-change action was a little on the heavy side but noticeably less so than on the .Tiger Cub with a similar

gearbox tested last year. The mounting of the clutchoperating fluid reservoir and exposed cables on the steering column give a crude appearance, out of keeping with the rest of the interior.

The Blackpool Duple factory had made a neat job of mounting the switches, radio controls, etc., and these could all be reached quite easily by the driver, although it would be necessary for him to memorize some of the positions. The instrument panel was badly positioned, however, the speedometer being obscured by the steering wheel hub. The windscreen bottom rail was a little higher than on most underfloor-engined models with consequent slight toss of vision immediately in front of the vehicle, although this was not noticeable in normal driving.

The standard of comfort given by the passenger seats in the Dragonfly body was very good, the choice of 49 as the seating capacity allowing adequate leg room. The interior finish was attractive and the slender pillars helped in giving good vision. Creaks and rattles were conspicuous by their absence, apart from one minor front-end squeak.

Virtually complete access to the engine and other amidships-mounted units is given through the openings in the side skirts and floor. The fuel injection pump and governor are more accessible than on most models of this layout, being mounted in an upright position on the nearside of the engine just below frame level.

Whilst the Leopard in the form tested is not the fastest chassis in its class it has the characteristic of covering the ground quite rapidly without seeming to require conscious " pushing " by the driver. A slightly higher top gear would undoubtedly suit it on motorways, the 4-111 to I singlespeed axle being probably about right for this purpose although it would limit the maximum gradient ability to something like 1 in 7 fully laden, quite apart from not giving the fluency of performance of the two-speed unit. The highest combination of two-speed axle ratios available, 3.31 and 4-5 to 1 seems likely to give too high an overall top gear to be practical under most conditions. For most operators' duties the vehicle seems to strike a happy balance between performance and economy, with outstanding refinement, just as it is.