ROADSIDE AND GARAGE.

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

A Page for Drivers, Mechanics and Foremen

When Replacing Heavy Road Wheels.

The sender of the following communication has bee)! awarded the extra payment of 5s. this week.

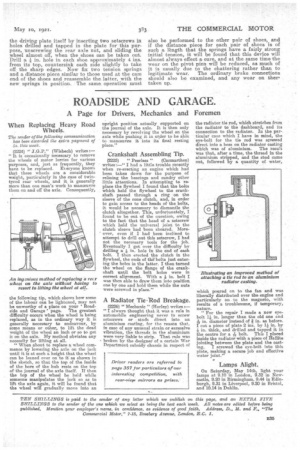

(2224) " J.G.P." (Wisbech) writes:— " It is occasionally necessary to remove the wheels of motor lorries for various purposes, and, just as frequently, they have to be replaced. Rceryone knows that these wheels are a considerable weight, particularly in the case of twintyrecl rear wheels, and it is generally more than one man's work to manoeuvre them on and off the axle. Consequently,

the following tip, which shows how some of the labour can be lightened, may not be unworthy of a place on your 'Roadside and Garage' page. The greatest difficulty occurs when the wheel is being replaced, as in the ordinary way it is generally necessary to endeavour' by some means or other, to lift the dead weight of the wheel an inch or so to get it on the axle. My method obviates any necessity for lifting at all.

"When about to replace a wheel commence by lowering the axle on the jack until it is at such a height that the wheel can be leaned over on to it as shown in the sketch, so that the top of the inside of the bore of the hub rests on the top of the journal of the axle itself. If then the top of the wheel be held while someone manipulates the jack so as to lift the axle again, it will be found that the wheel will gradually move into an upright position actually supported on the journal of the axle. It is then only necessary by revolving the wheel on the axle while pushing it in order to be able to manoeuvre it into its final resting place."

Crankshaft Assembling Tip.

(2225) " Peerless " (Carmarthen)

writes :—" I had a little trouble recently when re-erecting an engine which had been taken down for the purpose of relining the bearings and sundry other little attentions. In attempting to replace the flywheel I found that the bolts which held' the flywheel to the crankshaft passed through a ring on the sleeve of the cone clutch, and, in order to gain access to the heads of the bolts, it would be necessary to dismantle the clutch altogether. This, unfortunately, I found to be out of the question, owing to the fact that the head of a setscrew which held the universal joint to the clutch sleeve had been sheared. More' over, even if I had been inclined to attempt to drill out this setscrew, I had not the necessary tools for the job. Eventually I got over the difficulty by drilling a k in. hole in the end of each bolt. I then erected the clutch in the flywheel, the ends of the-bolts just entering the holes in the latter. I then turned the wheel on the flange of the crankshaft until the bolt holes were in correct alignment. With a kin, bolt I was then able to draw them into position one by one and hold them while the nuts were screwed in place."

A Radiator Tie' Rod Breakage.

(2226) "Mechanic " (1=forley) writes :— "I always thought that it was a rule in automobile engineering never to screw setscrews or studs direct, into an aluminium casting, fnr the reason that, in case of any unusual strain or excessive vibration, the threads in the aluminium were very liable to strip. That rule was broken by the designer of a certain War Department subsidy chassis in respect of

the radiator tie rod, which stretches from the radiator to the dashboard, and its connection to the radiator. In the particular case which I have in mind, the eye-bolt for the tie rod was screwed direct into a boss on the radiator casting which was of aluminium. The result was that, after a time, the thread in the aluminium stripped, and the stud came out followed by a quantity of water

which poured on to the fan and was liberally distributed over the engine and particularly on to the magneto, with results of a troublesome, if temporary, nature.

"For the repair I made a new eyebolt 11, in. longer than the old one and ,Irg in. diameter instead of in. as before. I cut a piece of plate 2 ins, by 1410. by in. thick, and drilled and tapped it in the centre for a fdbolt. This I_placed inside the radiator with a piece of Rallite jointing between the plate and the cast

ing. I screwed the eye-bolt into this plate, making a. secure job and effective water joint."

Lamps Alight.

On Saturday, May 14th, light your lamps at 9.10 in London, 9.32 in Newcastle, 9.20 in Birmingham, 9.44 in Edinburgh, 9.31 in Liverpool, 9.20 in Bristol, and 10.14 in Dublin.