71 ° ) CrThED „ C07 Vehi ( cle ao) by Preceptor

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

Steering, 8

CONSIDERABLE effort is required to turn the steering wheel on a heavy commercial vehicle, especially when the vehicle is loaded and is moving slowly. Vehicles with twinsteered axles have four wheels in contact with the road and even greater effort is required to steer them.

A lower gear ratio in the steering box makes the steering wheel easier to turn but more turns of the steering wheel from lock to lock are then required. This may be dangerous when the driver has to make the vehicle deviate rapidly to avoid a danger.

On many modern vehicles power assisted steering is fitted as standard to overcome this problem. Power steering must have a fail-safe characteristic, that is the driver must still be able to control the vehicle if the power-assistance fails. It must not take over all the effort required of the driver, in other words he must still be able to "feel the road".

Generally the system consists of an engine driven oil pump, which supplies oil under pressure to push against one side of a piston to provide the necessary assistance when it is required.

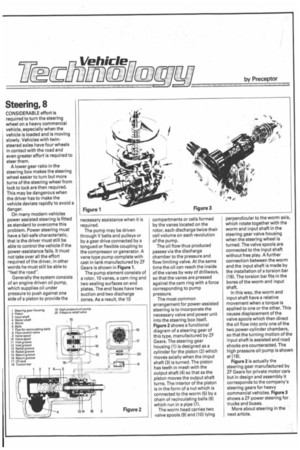

The pump may be driven through V belts and pulleys or by a gear drive connected by a tongued or flexible coupling to the compressor or generator. A vane type pump complete with cast in tank manufactured by ZF Gears is shown in Figure 1.

The pump element consists of a rotor, 10 vanes, a cam ring and two sealing surfaces on end plates. The end faces have two suction and two discharge zones. As a result, the 10 compartments or cells formed by the vanes located on the rotor, each discharge twice their cell volume on each revolution of the pump.

The oil flow thus produced passes via the discharge chamber to the pressure and flow limiting valve. At the same time the oil can reach the inside of the vanes by way of drillways, so that the vanes are pressed against the cam ring with a force corresponding to pump pressure.

The most common arrangement for power-assisted steering is to incorporate the necessary valve and power unit into the steering box itself. Figure 2 shows a functional diagram of a steering gear of this type, manufactured by ZF Gears. The steering gear housing (1) is designed as a cylinder for the piston (2) which moves axially when the imput shaft (3) is turned. The piston has teeth in mesh with the output shaft (4) so that as the piston moves the output shaft turns. The interior of the piston is in the form of a nut which is connected to the worm (5) by a chain of recirculating balls (6) which run in a pipe (7).

The worm head carries two valve spools (9) and (10) lying perpendicular to the worm axis, which rotate together with the worm and input shaft in the steering gear valve housing when the steering wheel is turned. The valve spools are connected to the input shaft without free play. A further connection between the worm and the input shaft is made by the installation of a torsion bar (18). The torsion bar fits in the bores of the worm and input shaft.

In this way, the worm and input shaft have a relative movement when a torque is applied to one or the other. This causes displacement of the valve spools which then direct the oil flow into only one of the two power-cylinder chambers, so that the turning motion of the input shaft is assisted and road shocks are counteracted. The high pressure oil pump is shown at (19).

Figure 2 is actually the steering gear manufactured by ZF Gears for private motor cars but in design and assembly it corresponds to the company's steering gears for heavy commercial vehicles. Figure 3 shows a ZF power steering for trucks and buses.

More about steering in the next article.