SMALL ENGINES FOR INDUSTRIAL PURPOSES.

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

Details of Two Alfa Power Units Suitable for Driving Lawn Mowers, Air Compressors, Lighting Dynamos, Fire Pumps, etc.

TWO small engines, one a twin of 9 h.a. and the other a four-cylinder

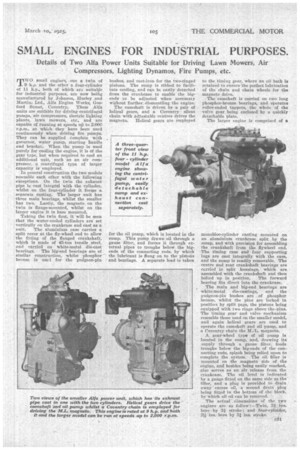

• of 11. h.p., both of which are suitable for industrial purposes, are now being manufactured by. Johnson, flurley and Martin, Ltd., Alfa Engine Works, Geeford Street, Coventry. These Alfa units are suitable for driving centrifugal pumps, air compressors, electric lighting plants, lawn mowers, etc., and are capable of running at speeds up to 2000, r.p.m., at which they have been used continuously when driving fire pumps. They can be supplied complete with governor, water pump, starting handle and bracket. When the pump is used purely for cooling the engine, it ia of the gear type, but when required to cool an additional unit, such as an air compressor, a centrifugal type of larger capacity is employed.

In general construction the two models resemble each other with the following exceptions. On the twin the exhaust pipe is cast integral With the cylinder, whilst on the four-cylinder it forms a separate casting. The larger unit has three main bearings, whilst the smaller has two. Lastly, the magneto on the twin is 'flange-mounted, whilst on the larger engine it is base mounted.

Taking the twin first, it will be seen that the water-cooled cylinders are set vertically on the crankcase and cast as a unit. The aluminium case carries a split cover at the fly-wheel end to allow the fitting of the flanged crankshaft, which is made of 45-ton tensile steel, and carried on white-metal die-cast bearings. The big-end bearings are of similar construction, whilst phosphor bronze is sisal for the gudgeon-pin bushes, and east-iron for the two-ringed pistons. The sump is ribbed to facilitate edoling,. and can be easily detached from the crankcase to enable the bigends to be adjusted when necessaty without further.diamantling the engine. . The camshaft is driven by a Pair of helical gears, and a Coventry silent chain with adjustable centres drives the magneto. Helical gears are employed for the oil pump, which is located in the sump. This primp draws oil through a gauze filter, and forces it through external pipes to troughs below the bigends of the connecting rods, by which the lubricant is flung on to the pistons and bearings. A separate lead is taken to the timing gear, where an oil bath is retained to ensure the perfect lubrication of the chain and chain wheels for the magneto drive.

The canaShaft is carried on two long phosphor-bronze bearings, and operates roller-ended tappets, the whole of the valve gear being enclosed by a quickly detachable plate.

The larger engine is comprised of a

monobloe-cylinder casting mounted on an aluminium crankcase split by the sump, and with provision for assembling the crankshaft from the flywheel end. The timing case and four supporting lugs are cast integrally with the case, and the sump is readily removable. The centre and rear erankshaft bearings are carried in split housings, which are assembled with the crankshaft and then bolted up in position. The forward bearing fits direct into the crankcase.

The main and big-end bearings are white-metal die-castings, and the gudgeon-pin bushes are of phosphor bronze, whil§t the pins are locked in position by split pegs, the pistons being equipped with two rings above the-pins. The timing gear and valve mechanism resemble those Used on the smaller model, and again helical gears are used to operate the camshaft and oil pump, and a Coventry chain the M.-L. magneto.

A gear-wheel type of oil pump is located in the sump, and, drawing its supply through a gauze filter, feeds troughs below the big-ends of the connecting rods, splash being relied upon to complete the system. The oil filler is mounted on the magneto side of the engine, and besides being easily reached, also serves as an air release from the crankcase. The oil level is indicated by a gauge fitted on the same side as the filler, and a plug is provided to drain away excess oil, a second drain plug being fitted in the bottom of the block, by which all oil can be removed.

The actual dimensions of the two engines areas follow

bore by 3! stroke ; and four-cylinder, 2}k ins, bore by 3! ins. stroke. .