A CLEAN

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

SWEEP

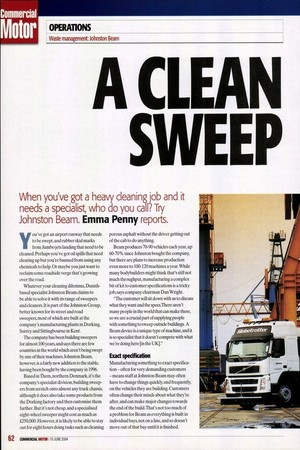

When you've got a heavy cleaning job and it needs a specialist, who do you call? Try

Johnston Beam. Emma Penny reports.

you've got an airport runway that needs to be swept, and rubber skid marks from Jumbo jets landing that need to be cleaned. Perhaps you've got oil spills that need clearing up but you're banned from using any chemicals to help. Or maybe you just want to reclaim some roadside verge that's growing over the road.

you've got an airport runway that needs to be swept, and rubber skid marks from Jumbo jets landing that need to be cleaned. Perhaps you've got oil spills that need clearing up but you're banned from using any chemicals to help. Or maybe you just want to reclaim some roadside verge that's growing over the road.

you've got an airport runway that needs to be swept, and rubber skid marks from Jumbo jets landing that need to be cleaned. Perhaps you've got oil spills that need clearing up but you're banned from using any chemicals to help. Or maybe you just want to reclaim some roadside verge that's growing over the road. Whatever your cleaning dilemma, Danishbased specialist Johnston Beam claims to be able to solve it with its range of sweepers and cleaners. It is part of the Johnston Group, better known for its street and road

sweepers, most of which are built at the company's manufacturing plants in Dorking, Surrey and Sittingbourne in Kent.

The company has been building sweepers for almost 100 years, and says there are few countries in the world which aren't being swept by one of their machines. Johnston Beam, however, is a fairly new addition to the stable, having been bought by the company in 1996. Based in Them, northern Denmark, it's the company's specialist division, building sweepers from scratch onto almost any truck chassis, although it does also take some products from the Dorking factory and then customise them further. But it's not cheap, and a specialised eight-wheel sweeper might cost as much as £250,000. However, it is likely to be able to stay out for eight hours doing tasks such as cleaning

porous asphalt without the driver getting out of the cab to do anything.

Beam produces 70-90 vehicles each year, up 60-70% since Johnston bought the company, but there are plans to increase production even more to 100-120 machines a year. While many bodybuilders might think that's still not much throughput, manufacturing a complex bit of kit to customer specifications is a tricky job, says company chairman Dan Wright.

"The customer will sit down with us to discuss what they want and the specs.There aren't many people in the world that can make these, so we are a crucial part of supplying people with something to sweep outside buildings. A Beam device is a unique type of machine, and it is so specialist that it doesn't compete with what we're doing here [in the UK]."

had specification

Manufacturing something to exact specification — often for very demanding customers — means staff at Johnston Beam may often have to change things quickly, and frequently, on the vehicles they are building. Customers often change their minds about what they're after, and can make major changes towards the end of the build.That's not too much of a problem for Beam as everything is built in individual bays, not on a line, and so doesn't move out of that bay until it is finished.

A Beam sweeper is built using a standard range of hoppers., power-packs and soon, but they are used in E. pick-and-mix fashion.This means most machines are unique, and are designed to precl sely meet each customer's requirements.

Even after the machines are finished and out working witt customers, a member of the Beam team will often visit just to see how they are performing. With such individual machines being built at Them, many are prototypes and the manufacturer is keen to see how they are getting on in practice.

Steve Douglas,Johnston's marketing director, says the company is trying to stimulate people's imagination about the potential for Beam machines. 'The difficulty with this type of product is limiting people to what they want," he explair s.

Brush and noz de gear are among some of the standard bits of kit offered by Beam, but it can fit telescop c arms, allowing machines to sweep lm one either side of the vehicle —handy for rippilg up roadside weeds, he adds.

The British Army has recently bought some Johnston Beam vehicles, specifically to sweep roads after its tanks have crossed them, particularly where mud is compacted."They wanted to avoid the mud smearing, so they took a machine with a full length scraper on a telescopic ram ‘74/hich lifts the mud, then the sweeper does the rest." Full-width nozzles on other machines allow roadbuilders to sweep and clean roads they are constructing. When roads are being 111 Getting rid of the !Fosse spills

put down in layers, they must be very clean before the next layer is added, hence Johnston's involvement.

And when things need to be even cleaner, there's an option for a high-pressure water system which can operate at up to 600bar, using 200 litres of water a minute to drive out dirt.

Among some of the more unusual pick-andmix parts offered are machines which will do tunnel and barrier washing, road edge cutting, white line removal, and a hot water system which operates at 600 bar and 90°C.

Cement factories

This high-pressure hot water system is being used on machines in cement factories, where they achieve a clean job in a very dusty environment, and at harboursides where the hot water system cuts through greasy spillages and the suction picks up heavy industrial debris.

It's also undergoing tests for airport rubber removal —Heathrow currently spends £300,000 a year on removing rubber deposited by plane tyres from its runways, and Johnston says high pressure and hot water could remove the need for detergents, something the British Airport Authority is keen to achieve. Airports often rely on Beam machines for high-speed removal of foreign object debris (FOD) on runways. According to Douglas, FOD damage on planes costs the Ministry of Defence £26m a year —jets such as the Harrier have low air intakes, so they take in more debris and are more susceptible to damage. Often there is only a 90-second window to clean a runway between planes,so speed and efficiency are crucial. •