Cift Seavuig Special

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

Drivers train for tanker hazards

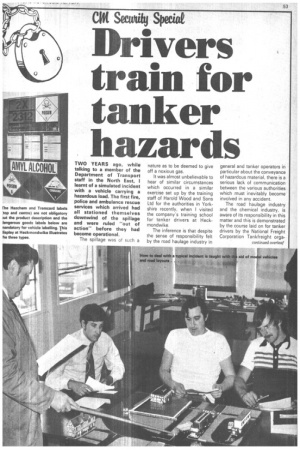

rhe Hazchem and Tremcard labels top and centre) are not obligatory mt the product description and the langerous goods labels below are nandatory for vehicle labelling. This lisplay at Heckmondwike illustrates he three types.

TWO YEARS ago, while talking to a member of the Department of Transport staff in the North East, I learnt of a simulated incident with a vehicle carrying a hazardous load. The first fire, police and ambulance rescue services which arrived had all stationed themselves downwind of the spillage and were ruled "out of action" before they had become operational.

The spillage was of such a nature as to be deemed to give off a noxious gas.

It was almost unbelievable to hear of similar circumstances which occurred in a similar exercise set up by the training staff of Harold Wood and Sons Ltd for the authorities in Yorkshir'e recently, when I visited the company's training school for tanker drivers at Heckrnondwike.

The inference is that despite the sense of responsibility felt by the road haulage industry in general and tanker operators in particular about the conveyance of hazardous material, there is a serious lack of communication between the various authorities which must inevitably become involved in any accident.

The road haulage industry and the chemical industry, is aware of its responsibility in this matter and this is demonstrated by the course laid on for tanker drivers by the National Freight Corporation Tankfreight orga nisation at its Harold Wood training centre.

Apart from the carriage of inflammable fuels, the number of hazardous chemicals is increasing annually as chemical compounds become more complex.

Hazchem and Tremcard labelling schemes have gone some way to make available information about the nature of the load being carried, but tanker drivers need to know the facts and the techniques. These they are taught at Heckrnondwike.

All those who drive tankers for the company, including drivers who are hired in from time to time, must take the course to confirm their competence in undertaking such work.

Indeed, the course introduction is aimed at evaluating their knowledge and experience in tanker operation. If necessary, the course can be extended from two or three days to include a visit to an ICI installation so that the effect of various chemicals can be demonstrated practically. For inexperienced personnel, trips with experienced drivers are arranged.

At the training centre, emphasis is placed on the preservation of life when an incident occurs, but stress is laid particularly on the driver's. responsibility to preserve his own senses and mobility. For he is probably the most important source of information about the vehicle and its load.

With this in mind, instruction is given about the nature of a selection of commonly carried chemicals and their effect on people coming into contact with them or the vapour they give off.

The basis of this is extracts from Tremcards. Armed with this knowledge, the driver is more able to appreciate the two procedures which are laid down arid which must be carried out when a spillage or accident Occurs.

These procedures cover leakage or spillage when the vehicle is being loaded or unloaded at company or customers' premises and when in transit or involved in an accident.

Obviously, in the first of these, experienced help is usually available but the procedure lays down that the driver must not leave the premises till he has made sure that the vehicle and the area concerned is clean.

Though a procedure is laid down to meet the second set of circumstances, drivers are taught that they must use their i-iitiative in establishing a prior

ity of action.

Instruction is given about the various types of fire extinguishers though only one type is commonly carried in Harold Wood's vehicles. Woe betide the driver who has occasion to use the vehicle-mounted fire extinguisher and who does not ensure that it is refilled or replaced immediately afterwards. The company takes a very serious view of any vehicle which is left with an ineffective fire extinguisher and will trace the omission back to the driver concerned to take disciplinary action. There is always someone at the depot who will refill or repla€e a used extinguisher, I was told, but even a note left on the vehicle in a prominent place to the effect that the appliance requires replacement will be accepted in the extreme case.

Each driver is issued with a personal safety clothing kit comprising helmet, goggles and/or eye shield, a one piece boiler-suit type pvc overall, gloves arid rubber boots. An eyewash bottle is also part of the kit.

Drivers are shown hovi:i to put this on quickly arid properly with the gloves inside the sleeves of the suit arid the trouser leg over the tops of the rubber boots.

According to the nature 01 the product carried on ari). particular trip, a driver will alsc be issued with breathinc apparatus. Some of these kit are stationed at the premises o. selected customers so that driver diverted to pick up chemical which calls for thi possible use of breathinc apparatus will not find himsel without the equipment in ar

emergency.

Where this procedure is invoked, the apparatus is returned to its base within 24 hours.

Drivers are taught about tank types and construction anci safety rules for filling and emptying tanks including avoiding spillage of residue in the pipe as loading is completed.

This is important because constant spillage can present cleaning problems.

Exterior cleanliness is considered to be as important as a clean interior and spillage of corrosive material on the outside of a tank has an obvious effect.

Moreover, spillage of bituminous resins not only give the vehicle an untidy appearance but extended to the running gear it entails vigorous cleaning for such things as MoT tests.

Finally, but not least important is the proper marking and labelling of the vehicle for the carriage of hazardous materials.

By law, the vehicle must carry four labels comprising the hazardous load diamonds at front and rear of the tank and two labels with the name of the product carried on each side of the vehicle.

To these must be added the optional Hazchem or Tremcard labels. Neither of these schemes is obligatory and though Harold Wood prefers the Hazchem system its customers might prefer Tremcards.

The result is that the vehicle might, therefore, carry the four mandatory labels, four Hazchem labels and four Tremcards; a total of 12 labels.

Drivers are made aware of the significance of all of these and learn which customers will require the Tremcards to be carried. Customers' requirements are expected to be met even as far as using the customer's own protective clothing types to conform with their own laid down safety rules.

Practical work illustrates the theory taught. Syndicate work on set incidents is arranged with the use of model vehicles and road layouts and this introduces a competitive element into the instruction to encourage trainees to absorb knowledge.

At the end of the day, a specially prepared drivers' handbook which is issued to each driver acts as a reminder to the trainee of all that he has learnt during the course.

Perhaps most important, it includes company emergency telephone numbers from which assistance can be summoned and a reminder to notify customers' emergency services where appropriate.

• Johnny Johnson