TRIPLE-CONTAINER BODYWORK FOR COKE DELIVERIES

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

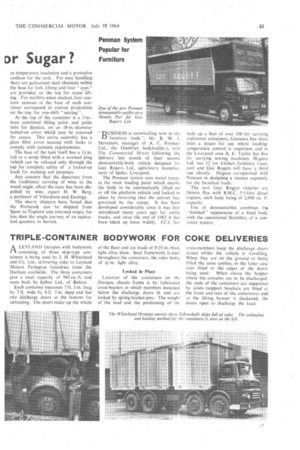

ALEYLAND Octopus with bodywork consisting of three skip-type containers is being used by J. H. Whitehead and Co. Ltd., delivering coke to Leyland Motors Farington foundries from the Durham coalfields. The three containers give a total capacity of 945 cu. ft, and were built by Edbro Ltd., of Bolton.

Each container measures 7 ft. 3 in. long by 7 ft. wide by 6 ft. 5 in. deep and has two discharge doors at the bottom for unloading. The doors make up the whole of the floor and are made of 0.25-in.-thick light alloy plate, Steel framework is used throughout the containers, the sides being of h-in. light alloy.

Locked in Place Location of the containers on the Octopus chassis frame is by fabricated cross-bearers in which members mounted below the discharge doors fit and are locked by spring-loaded pins. The weight of the load and the positioning of he cross-members keep the discharge doors closed whilst the vehicle is travelling. When they are on the ground or being lifted the same applies, in the latter case eyes fitted to the edges of the doors being used. When above •the hopper where the contents are to be discharged. the ends of the containers arc supported by joists (support brackets are fitted at the front and rear of the containers) and as the lifting shawser is slackened, the doors open to discharge the load.