Composite Head in A Resume of Patent Novel Engine Construction Recently Been Published

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

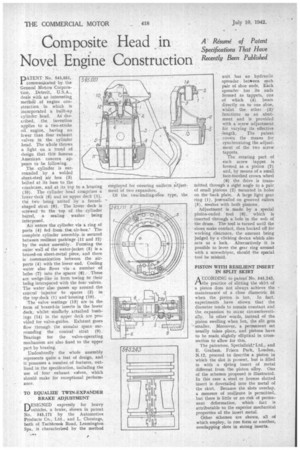

DATENT No. 545,051, communicated by the General Motors Corporation, Detroit, U.S.A., deals with an interesting metho'd of engine construction in which is incorporated a built-up

cylinder. head. As described, the invention applies to a two-stroke oil engine, having no fewer than four exhaust valves in the cylinder head. The whole' throws a light on a trend of design that this famous American concern appears to be following.

The cylinder is surrounded by a welded sheet-steel air box (3) bolted at its base to the crankcase, and at its top to a housing (10). The cylinder head comprises a lower .deck (6) and an upper deck (1), the two being united by a funnelshaped strut (9). The lower deck is screwed to the top of the cylinder barrel, a sealing washer being interposed.

Air enters the cylinder via a ring of ports (4) fed -from tht air-box.' The complete cylinder assembly: is secured between resilient paekings (11 and 12) by the outer assembly. Forming the outer wall of the water-jacket (5) is a brazed-on sheet-metal piece, and there is communication _between the airports (4) with the lower end. Cooling water also flows via a number of holes •(7) into the spaces (8). These are wedge-like in form -owing to their being interspaced with the four valves. The water also passes up around the central injector to spaces (2) in the top.deck (1) and.bousing (10).

The valve seatings (13) are in the form of brazed-in inserts in the lower deck, whilst similarly attached bushings (14) in the upper deck are provided for valve-guides. Exhaust gases flow through the annular space surrounding the conical strut (9). Bearings for the valve-operating mechanism are also fixed to the upper part by brazing.

undoubtedly the whole assembly represents quite a feat of design, and it possesses a number of features, outlined in the specification, including the use of four exhaust valves. which should make for exceptional performance.

TO EQUALIZE TWIN-EXPANDER BRAKE ADJUSTMENT

DESIGNED expressly for heavy 1/vehicles, a brake, shown in patent No. 545,171 by the Automotive Products Co., Ltd., and L. Chouings, both of Tachbrook Road, Leamington Spa, is characterized by the method

unit has an hydraulic spreader between each pair of shoe ends. Each spreader has its ends formed as tappets, one of which (4) bears directly on to one shoe, whilst the other (3) functions as an abutment and is provided with a screw adjustment for varying its effective -length. The patent covers the means for synchronizing the adjustment of the two screw tappets.

The rotating part of each screw tappet is formed as a pinion (7) and, by means of a small face-toothed crown wheel (8) the drive is transmitted, through a right angle to a pair of small pinions (2) mounted in-holes on the-back plate. A large light gear rip., (1), journalled on grooved rollers (5)7 meshes with both pinions.

Adjustment is made by a special pinion-ended -tool (6), which is inserted through a hole in the web of the drum. The tool is turned until the shoes make contact, then backed off for working clearance, the amount being judged by a clicking device which also acts as a lock. Alternatively it is possible to lever the gear ring around with a screwdriTer, should the special tool be mislaid.

PISTON WITH RESILIENT INSERT IN SPLIT SKIRT

ACCORDING to patent-No. 545,243, the practice of slitting the skirt of a piston does not always achieve the maintenance of a close diametric fit when the piston, is hot. In fact, experiments have shown that the diameter tends to remain constant and the. expansion to occur circumferentially. In other' words, instead of the piston swelling when hot, the slit gets smaller. Moreover, a permanent set usually takes place, and pistoni have to he made slightly elliptical in crosssection to allow for this.

The patentees, Specialloic1.7 Ltd., and E. Graham, Friern Park, London, N.12, proceed t0 describe a piston in which the slot is present, but is filled in with a spring insert of metal different from the piston alloy. One of the schemes proposed is illustrated. In this case a steel or bronze slotted insert is dovetailed into the metal of the skirt. Because the slots overlap, a measure of resilience is permitted, but there is little or no risk of permanent deformation, which fact is attributable to the superior mechanical properties of the insert metal.

Other schemes .are shown, all of which employ, in one form or another, overlapping slots in strong inserts.