MAKING DEFECTIVE PARTS AS GOOD AS NEW.

Page 105

Page 106

If you've noticed an error in this article please click here to report it so we can fix it.

Some Particulars of the Latest Repair Processes Adopted by Barimar, Ltd.

ATOUR of the works of Barimar, Ltd. (Motor Vehicle Department), 18, Lamb's Conduit Street, Holborn, London, W.C.1, would be a revelation to the average user of commercial vehicles of the manner in which a vast variety of components of all shapes and sizes is repaired or otherwise renovated by methods which have resulted from many years of experience with this class of work. Representatives, of this journal pay periodical visits to the works with a view to studying the new means and processes which are being employed, and they • are seldom disappointed, as, there is nearly always something fresh, *constituting either an improvement upon an older process or something entirely new.

From the work which has been tackled it would seem that if an engine or other major Unit of a chassis were practically blown to pieces the owner need not despair. Perhaps this is going too far, but certainly some of the jobs which have been done hate involved an astonishing amount of building up, the finished product not being passed by the inspection department until the repair has proved to be absolutely sound and the accuracy of the finish unimpeachable.

It might be thought that a welded part would seldom be as strong as the original, • but the experience of the welders shows this to he quite a mistaken impression. A sound welding repair does not mean attention only to the point of fracture. In many instances such fractures are due to inherent weaknesses in the design or the . material, and, wherever possible, the surrounding metal is reinforced by -welding Metal of good quality. Sharp inner corners are well radiused and, in certain instances, fatigued metal is cut right away and replaced by thoroughly sound welded metal.

It is noticeable to the visitor that a large proportion of the work is concerned with commercial vehicles. This is no doubt because these vehicles suffer much harder, usage and run a mileage out of all proportion to the private car.

Much of the work is the repairing of cracked cylinders. Weaknesses appear to develop in cylinders, even in what are considered to be the hest makes of _chassis, and they tend to show how difficult it is not only to provide perfect castings but to eliminate internal stresses caused either during the 'cooling after casting or by unequal expansion while the engine is running. Cracks often develop across the valve seats between valve-plug orifices, and sometimes in the bores themselves. Nearly every make of cylinder has its little voaknesses. Biker cylinders, for instance, are often found to be cracked around the valve pocket on the exhaust .side. The replacement of such cylinders by new does not always remove the trouble, because the new may still possess the same inherent weakness, whereas often repaired cylinders are actually stronger than new.

A common trouble is excessive wear and sometimes cracking of the valve seatings, which are then built up and recut. After repair, cylinder bases are always cleaned up in the Shaping machine. This is because the beating in the muffle (which is essential before even a seating repair), by removing the initial stress, may cause a settling Which will throw the base slightly out of alignment. The bores are also tested and cleaned up if necessary.

A comparatively new process which is proving very successful is, the fitting of new cylinder

• sleeves, this being done when one or more bores are badly damaged or cracked. through to the water jacket. Iti such cases the defective bores; are opened -out and a 3-mm. sleeve inserted in each, the same pistons being utilized if these be in good condition. This sleeving process rim niso hr employed in the case of worn cylinders to bring them back to the maker's standard. It is cheaper, because often only one here is worn to any considerable degree, also no new, pistons are

• required. It is a matter of *judgment in individual cases as to whether it is better to do this sleeving process or to grind out the bores and fit new pistons. . As a matter . of fact, most commercial-vehicle owners prefer, if possible, to keep to the standard piston, as it saves a lot of difficulty in the maintenance of stocks and as regards interchangeability.

In some instances, where the bores are badly scored and worn as well, the scores are filled in by welding and the cylinders then reground. In this manner not so Much metal has to be taken Out in regrinding the average amount of metal removed is .5 mm. to 1 .mm. There is an average saving of something like 75 per ednt. over the fitting of new cylinders. Ordinary scoring of cylinders not otherwise too worn can, of course, be repaired by the well-known Barimar process, which does not involve muffle heating and can be done very rapidly.

The most striking section of the renovation work concerns broken crankshafts. This part of a commercial-vehicle engine may be considered as the most vital and the one which, n5I

above all others, must be perfect. The average user who

• has not had much experience with this class of repair may look askance at a welded shaft, but he need have no compunction, for Such shafts repaired in the manner we inspected, and at a cogt of approximately one-third that of a new shaft, can be expected to give service at least equal to that of a shaft when new ; in fact, in many cases broken shafts which are weak through faulty design can be built up and strengthened at the weak points. Nickel-steel is utilized for such repairs, and in carrying them out the two parts of the shaft are tacked together with a small amount of welding metal, this permitting bending to ensure correct alignment, and so accurately are such repairs carried out that often it is unnecessary even to skim the journals in the lathe. Sometimes completely new parts are embodied. For instance, in one crankshaft which we examined, and which had a diagonal break through a crankpin, a complete new pin was being fitted, this being coned into the webs before welding.

Similarly, axle shafts with broken ends are usually provided with completely new ends, the inner portions of which are ". pencilled " off.

We examined a number of hand-press screws, of which some hundreds have already been repaired without a hingle failure. These screws arrive in lots of a dozen, and are always broken at the neck where the metal at the fracture shows an open grain due td fatigue. In the repair the defective metal is cut right away and replaced by high-quality welding metal, which is not liable to the same degree of fatigue.

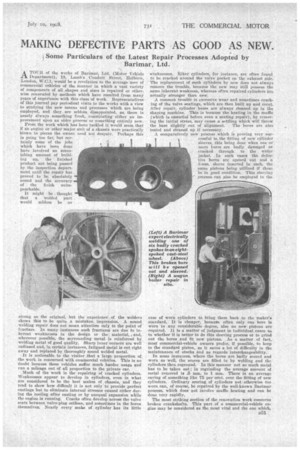

Welding is not confined to iron or steel. Malleable castings can be dealt with satisfactorily, and repairs to aluininium crankcases etc., are common. One particularly interesting job which. we examined was an eight-spoked caststeel road wheel, in which six of the spokes had cracked right through close to the rim, probably as the result of initial stresses due to uneven cooling, the weaknesses showing themselves after experiencing a certain amount of road shock. Each .crack was wed out almost to the centre of the spoke and electrically welded. A repair of this nature not only gives strength to the part treated but removes the initial tension in the spokes.

Every repaired part is carefully tested before issue, cylinders, for instance, being sebjected to an hydraulic pressure of 60 lb. iier square inch; likewise, every job is issued with a guarantee. Most of the work is so carefully carried out that very few persons, even experts, could detect differences between parts new and welded.

The company also does complete engine overhauls, including regrinding, but it does not undertake work which could be done in the ordinary garage, having no desire to enter this province by taking work from the general commercial vehicle repairing trade.

We have only been able to touch upon certain sections of the work. As a matter of fact, there are many others, including the supply of new crankshafts for replacements, special lightweight pistons for the smaller types of enginechassis-frame repairs, re-metalling of bearings, radiator and lamp renovations and the supply of cast-aluminium numberplates.