FORD TALKS.

Page 23

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

A Series of Interesting Dialogues that have Tended Towards a Better Understanding of the Ford by the Men Who have to Run It.

By R. T. Nicholson (Author of "The Book of the Ford").

"I BELIEVE," said the manager, "in encouraging my drivers to come to me with questions. Some peopie think that. drivers will waste a lot of time with such questions ; that the answers to their questions will, at best, give only that 'little learning' which is ' dangerous ' ; that the less a driver knows of theory the 'better he will make good in practice. But I have never found it that way. Of course, -I do not encourage my drivers to muddle about with the ' innards' ; it is their business to drive, not to tinker ; but I have found that the driver who knows ' how ' will often be able to go on driving on a round when the mere driver would be stranded by some slight trouble. The few hours I have spent in answering questions (generally beginning with 'It bothers me—') have been well worth whale."

"What Bothers Me,"—The Question of Wiring.

"What bothers me," said Smiff, a van driver, "is why there is so much more wiring about the Ford than about any other motor. We hear a good deal about wireless these days; but they don't seem to think much of it at the Ford works. The Wirt35 are always getting soaked with oil and water, and .frayed and cut; and that means that they leak electricity and cause shorts, and hang a man up when he wants to get through his round."

" A very sensible queation," I replied to Smiff. " There does seem to be a lot of wiring about the Ford, and if there's a lot that you can see, there is a lot more that you can't." .

" Whereabouts? " asked Smiff.

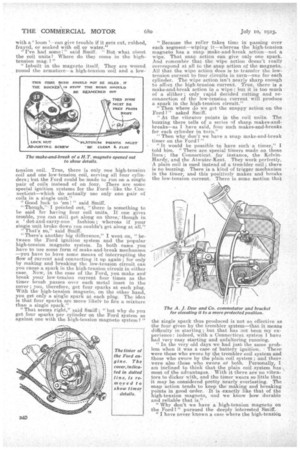

" In the coil units, for instance," I said. "There are two coils in each unit--one high-tension and one. low-tension. The low-tension coil has 220 turns of comparatively thick wire wound round a soft iron core, that core also consisting of lengths of wire. The high-tension coil has, roughly, a mile of wire "(no fewer than 16,400 turns). In • the four coil unit, therefore, there are over four miles of wire. Then, again, each stator coil consists of a length of flat wir e, or ribbon, wound round a spool. There being 16 such

stator coils, with turns each, there are 400 turns in all.. Then there is wire wound as field coils round the magnets in generator and starter, the .armatures of which are also wound with coils of wire. The generator armature has 21 coils of 10 turns each. 'filen the cut-out contains more coils—a series coil of 10 turns of heavy wire, and a voltage coil of 1,300 turns. The horn, too, has its coils and the cut-out and--"

" Blirny I " said Smiff.

"Yes, it does make you think, doesn't it? You begin to wonder why a Ford ever runs, when you think of all these wires on wires. • But there is rarely any trouble with the wires you can't see. They can't get cut or rubbed, and wires that ought to remain insulated are so carefully treated in process of mama 11(

1(1 facture that breakage and shorting rarely arise with them."

" Though the' did tell me at the garage that there was shorting–in my, stati3r coils when I had starting trouble last week."

"Yes, loss of insulation is always possible, but'it is unlikely to happen except with exposed wires. But don't run away with the idea thn.t there is a great deal more wiring on the Ford than on any other motor. All wiring systems are complicated. On the Ford more of the wiring is in evidence—that's all; and it is mostly in the ignition system that it is sticking out at all points. The Ford -magneto system is not self-contained, like the high-tension magneto system. In the h.t. magneto you have almost the same method of construction as in the Ford system, but it is, ao to speak, more,,under one hat.

"In the case of the Ford, you get a, lot of it under the bonnet! Your low-tension wiring runs from coil units, to timer. You see nothing corresponding to that if you have a high-tension ignition system ; but there is wiring corresponding to it inside the hightension magneto all the same. You must have your high-tension circuits, a-id you must have your lowtension circuits—one for each cylinder—and the high-tension wiring (forming part of the high-tension circuits) is always out in the open on all systems. In the Ford it is the low-tension wiring that, comes out into the open, it being buried out of sight in the high-tension magneto ; but it is there all the same. Being well out of sight, it is also out of all danger of being cut or rubbed, so that it rarely gives trouble ; whereas we all know that the law-tension wiring on the Ford—even though most of it is protected

with a loom '—can give trouble if it gets cut, rubbed, frayed, or soaked with oil or water. '

"I've had some!" said Srnift. " But what about the coil units? Where do they come in the hightension mag.? "

"Inbuilt in the magneto itself. They are wound _ round the armature—a high-tension coil and a low

tension coil. True, there is only one high-tension coil and one low-tension coil, serving all four cylinders; but the Ford could be made to run on a single pair of coils instead of on four. There are some special ignition systems for the Ford—like the Connecticut—which do actually use only no pair of coils in a single unit." " Good luck to 'em!" said Smiff.

" Though,":I pointed out, "there is something to be said for having four coil units. If one gives trouble, you can still get along on three,though in

dot-and-carry-one• fashion ; whereas if your single unit broke down you couldn't get along at all." That's so," said Smiff.

"There's another big difference," I went on, "between the .Ford ignition system and the popular high-tension magneto system. In both cases you have to use some form of make-and-break mechanism —you have to have some means of interrupting the flow of current and connecting it up again; for only by making and breaking the low-tension circuit can you cause a spark in the high-tension circuit in either case. Now, in the case of the Ford, you make and break your low-tension current four times as the timer brush passes •over each metal inset in the cover ; you, therefore, get four sparks at each plug. With the high-tension magneto, on the other hand, you get only a single spark at each plug. The idea is that four sparks are more likely to fire a mixture than a single spark." •

"That seems right," said Smiff "hut why do you get four sparks per cylinder on the Ford system as against one with the high-tension magneto system ? "

Because the roller takes time in passing over each segment—wiping 'it—whereas the high-tension magneto has a snap make-and-break action—not a wipe. That snap action can give only one spark. And remember that the wipe action doesn't really correspond at all to the snap action of the •magneto. All that the wipe action does is to transfer the lowtension current to four circuits in turn—one for each cylinder. The wipe action isn't nearly sharp enough to affect the high-tension current. True, there is a make-and-break action in a wipe ; but it is too much of a slither ; only rapid decided cutting and reconnection of the low-tension current will produce a spark in the high-tension circuit."

"Then where do We get the snappy action on the Ford?" asked Smiff.

"At the vibrator points in the coil units. The buzzing there tells of a series of sharp. makes-andbreaks—as I have said, four such makes-and-breaks for each cylinder in turn."

"Then why don't we have a snap make-and-break timer on the Ford? "

"It would be possible to have such a timer," I told him. "There are special timers made on those lines; the Connecticut_ for instance, the KelvinHardy, and the Atwater-Kent. They work perfectly. A plain coil is used instead of a trembler coil ; there is no buzzing. There is a kind of trigger mechanism in the timer, and this positively makes and breaks the low-tension current. There is some motion that

the single spark thus produced is not so effective as the four given by the trembler system—that it means difficulty in starting ; but that has not been my experience: indeed, with a Connecticut system I have had very easy starting and unfaltering running. In the very old days we had just the same problem when it was a case of battery ignition. • There were those who swore by the trembler coil system and those who swore by the plain coil system ; and there were also .those who swore at both. Personally, I am inclined to think that the plain coil system has \ most of the advantages. With it there are no vibrators to dicker with, and the timer wears so little that it may be, considered pretty nearly everlasting. The snap action tends to keep the making and breaking i points in good order. It s exactly like that of the high-tension magneto, and we know how durable and reliable that is."

"Why don't we have a high-tension magneto on the Ford? pursued the deeply interested Smiff. "I have never known a ease where the high-tension . magneto gave better results—on a Ford—than its own low-tension system. My belief is that, in slowrunning (as in starting), the Ford magneto gives a surer spark than the high-tension magneto; and it is at startihg time that we want that park to be sure. I don't put this down to the trembler action of the Ford system, but to the fact that the voltage of the Ford magneto is higher than that of the hightension magneto at slow speeds."

" We've •got away from the wiring," said Smiff. " Isn't there any way of protecting it from oil, water, and fraying? "

"Care has a good deal to do with it. if you slop oil and water about when you are filling up, the exposed wiring will suffer. Don't do it! Apart from that, lengths of easy-fitting rubber tubing passed over the wires at the timer end will help to protect them."

"Why isn't the timer somewhere else, out of the way of oil, water, and cuts? " " It quite well might be elsewhere," I answered. " There are a number of systems on the market by which the timer is set. at some point where the wires can be kept out of harm's way. There is no special reason why the timer is set where it is, excopt that It is mechanically convenient to have it there; for instance, it might be close to the coil box, where it could be kept perfectly clean. But it would be mechanically more difficult to run the brush there. By some means or other, the brush arm has to be rotated from the engine, and any change of position from that favoured by the Ford Co. means some extra complication—not much, perhaps, but some.

" There is no reason why the timer should not he run off the back end of the timing gear, except that it is difficult to find room for it there in the present crowded condition of things under the right-hand side —the carburetter side—of the bonnet. Well, .Smiff, get along and cover the ground; I think I've about covered it as regards that wiring, so you wire in! "