AIDS TO SOLVING FORD PROBLEMS.

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, which will Appeal to the Owner, Driver, and Repairer.

IN THIS series of hints concerning the Ford light chassis and ton truck wherever they are employed for ' commercial purposes, weendeavour to deal with the subject from every view-point, so that the advice given will appeal to the owner, driver, maintenance engineer, or mechanic: Valuable sources of information are being tapped for this purpose, and it should be understood that the information given will be derived from those with an intimate knowledge of the subject.

We shall welcome for inclusion amongst the hints those which have proved of value to individual Users, and will make suitable remuneration for any published. What; we desire aro the results of practice.

, 63.—The Ford with a Bias.

' Many Ford drivers are no doubt familiar with that • very peculiar bias to one side of the road which shows itself in the steering of the Ford vehicle. It is a weakness which makes the steering more irksome than need be, and it is not removed by altering the tracking of the wheels, unless the front axle and steering generally are reconditioned. ..

• After the vehicle has been operating for any considerable length of time, the spindle body and arm' bushes should be replaced. The wheels should be tried and, if loose, should be removed and the stationary and moving 'cones replaced if worn.' The ball caps should also be stripped and new parts fitted if the connections be loose. Then, but not before, the front wheels may be adjusted for track. There should be It in. less between the rims at the front compared with the distance between those at the rear.

An additional advantage of this alteration is that the life of the tyres on the front wheels will be considerably lengthened.

.64.—Improving the Lubrication of Stub-axle Pins.

The front axle spindle pins and bushes often have a comparatively short life, mainly owing to the fact that the means for lubricating these parts are hot very practicable.

If the minute oiler on each stub axle is not already, blocked with paint when the vehicle is first delivered, it quickly becomes stopped up with road dirt, and it is then next to impossible to persuade oil to pass down

to the bushes To overcome this trouble, drill and tap the spindle 'body to take a A-in, gas greaser or Stauffer lubricator. Position this at the front side'of the stub axle; midway between the top and bottom bushes. There is quite a large space between these two bushes, and this, will hold a supply of grease which will automatically lubricate the bushes for a considerable period and at the same time will perform thevery important function of excluding mud and water.

' Ford users who carry out this simple mat ter will, we think, be sur

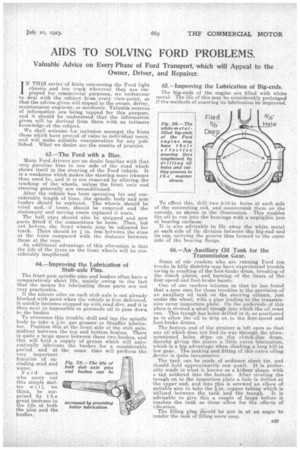

prised by t h e great increase in the life of both the ping and the bushes. 65.—Improving the Lubrication of Big-ends.

The big-ends of the engine /tie filled with white metal. The life of this may be considerably prolonged if the methods of ensuring its lubrication be improved.

To effect this, drill two 3-16-in holes at each side of the connecting rod, and countersiok them on the outside, as shown in the illustration. This enables the oil to run into the 'bearings with a negligible loss of bearing surfaces. It is . also advisable to file away the white metal it each side of the division between the big-end and its cap, carrying the groove thus formed to the outer side of the bearing flange.

66.—An Auxiliary Oil Tank for the Transmission Gear.

Sonic of our readers who are running Ford ton trucks in hilly districts may have experienced trouble owing to cracking of the-foot-brake drum, breaking of the clutch plates, and burning of the liners of the first-speed and foot-brake bands. One of our readers informs us that he has found that a sure cure for these troubles is the provision of' an auxiliary oil tank on the steering column, just under the wheel, with a pipe leading to the transmission cover inspection plate. On the underside of this plate is riveted a small trough into which the oil must run. This trough has holes drilled in it, sopositioned as to allow the oil to drip on to the first-speed and foot-brake drums.

.The bottom end of the strainer is left open so that any oil which does not find its way through the -aforementioned holes drips on theclutch-disc drum, thereby giving the plates a little extra lubrication, which is a big advantage when climbing a long hill in low gear. The making and fitting of this extra oiling ,device is eluite inexpensive. The tank can be made of ordinary sheet tin, and should hold approximately one quart. It is preferably Made in what is known as a kidney shape, with a tap soldered into the bottom. After riveting the trough on to the inspection plate a hole is drilled at the upper end, and into this is screwed an elbow of suitable size to take the 1-in. copper tubing -Which is Utilized between the tank 'and the trough. It is advisable to give this a couple of loops before it reaches the tank as these allow for the effects of vibration. The filling plug .ihuld be put in at an angle to render the task of filling more easy.