THE LOW LOAD LINE FOR REFUSE COLLECTION.

Page 13

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

A Clever Arrangement which Not Only Makes bin Discharging Easier, but Materially Accelerates Refuse Collecting by Dispensing with the Ladder.

TRE attainment of a low load line, in order to facilitate the transfer of the contents of refuse bins to the wagon which is to convey them to the destructor or dump, has been of considerable importance, not only in so far as the work itself is concerned, but because of its influence in affecting the choice between motor power and horse transport. With an infinitely more efficient means of traction in the petrol engine and with the inevitable extra cost entailed in keeping the engine running during the handling of bins and their contents, it is essential that the time during which the vehicle is necessarily stationary should be reduced to the minimum. In the case of the horsed vehicle, nothing is saved in fuel whether the animal be moving or standing still, and wastefulness does not enter into the matter, but, in the caseof the motor vehicle, the consumption of fuel could be avoided altogether if the engine could be stopped and quickly and economically restarted, but to attempt to operate the power plant in this way throughout a street of collections would actually entail a greater consumption of fuel and more labour on the part of the driver, and even occupy more time, than if the engine were left running. The best that can be done is to secure such a setting of the carburetter that the throttle is

only open at the minimum whilst idling.

So much for the engine. Where economy can really be effected during engine idling periods is in the facilitation of the loading. A considerable saving of time results from arranging to dispense with the ladder which the dustman has to put into position, mount with the loaded bin, descend and then bang up 'before the vehicle may again get on the move. The motor trade has very successfully tackled the problem. from this standpoint and has aimed at securing such a load line that the loader is able to tip the contents of a bin carried on his shoulder straight into the van from the pavement, and, moreover, ensuring that this advantage is not provided at the expense of body capacity.

With a body designed to tip endwise it is feasible to allow the wheel arch on each side to obtrude into the body space.

thus permitting the floor of the body to be set at least 6 ins, lower than if it is set down on the top of the wheel arch. The arch curving from front to rear, there is no obstruction which would hold any part of the load when the body is tipped. When sideways tipping is called for, however, the 6 ins, thus spoken about is lost, and the body must usually be raised on cross-bearers, mainly because the hinge centres are never brought out so far as the full width of the body. It always seems to us that if the combination of side tipping and a very low platform were called for it could be provided by designers.

A typical low load line vehicle is the S.D. Freighter made by Shelvoke and Drewry, Ltd., of Letchworth, Herts. The chassis with its low frame mounted on 20-in, diameter wheels provides a platform height of 23 ins., and a tipping body on this Freighter has a capacity of 2 tons and can be tipped to a very steep angle, whilst, because it is slightly tapered, with the greater width at the rear, there is a clear fall for the refuse. A very simple but efficient system of cables and pulleys opens the rear door as the front of the body rises, so that considerable time and labour otherwise spent on door opening by hand are saved.

The new Dennis low load line tipper

built for the Plymouth Corporation is mounted on a standard 2-ton chassis, and tips endwise. The body is constructed of steel, the sides being 2 ft. high, the upper 6 ins, of each of which is in the form of a hinged lip in three sections. When the flap is dropped, the loading height is 5 ft., and if the vehicle, as is usual in the circumstances, is standing by a kerb, the loader has only about 4 ft. 6 ins, to clear, whilst the maximum height when the flaps are raised and secured is then no more than 5 ft.

The wheel 'arches are taken up into the body, so that the bottom of the platform is virtually on a level with the tops of the wheels. The mudguards are attached to the framework and not to the body, The body is roofed over with six curved sliding half-doors running in grooves. Another feature of the body is the tapering outwards towards the rear, where it is 6 ins, wider than at the front, for easy discharge. The halfdoors open and are fastened back against the sides by chains, leaving a perfectly clear opening. The hydraulic tipping gear tips the body to an angle of 43 degrees.

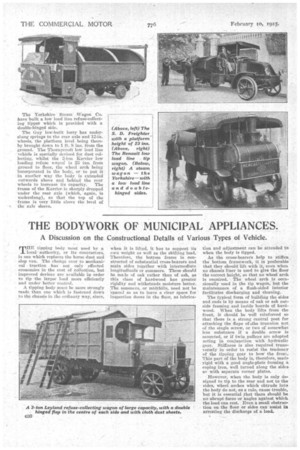

The Yorkshire • Steam -Wagon .Co. -have built a low load line refus-collecting' tipper which is provided with a double-hinged side.

The Guy low-built lorry has underslung springs to the rear axle and 12-in. wheels, the platform level being thereby _brought down to 1 ft. S ins, from the ground. The Thornyeroft low load line vehicle is specially devised for dust collecting, whilst the 3-ton Karrier low loading ref uSe wagon.' is 23 ins. from ground to floor, the wheel arch being Incorporated in the body, or to put it in another .way the body is extended outwards above and behind the rear

wheels to increase its capacity. The frame of the Karrier is sharply dropped under the rear axle (which, again, is anderslung), so that the top of the frame is' very little above the level of J.. the axle sleeve.