Why Additiv

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

reated Oils?

MANY operators seem to misunderstand the true purpose and function of so-called HD., or

"detergent "-type, engine oils. In certain instances high-speed oil engines, especially those operating under heavy-duty conditions, give rise to special lubrication problems. These problems take the form at deposits, causing piston scuffing, piston-ring sticking and crankcase sludges, which, unless resolved, can seriously restrict engine performance and service life. High-quality additive-treated engine oils, containing anti-oxidant and detergent materials, reduce such deposits, engine efficiency being thereby sustained for longer periods than when only high-grade straight mineral oils are used The detergent additive keeps finely divided contaminating material in suspension in the oil and prevents its deposition on engine parts. The suspended materials are so fine that they will pass through the normal types of engine-mounted filter; their presence has no detrimental effect on bearing surfaces and materials, whether they be of the hardor soft-alloy type. In functioning in this manner the oil rapidly becomes darker in colour, indicating that it is performing its detergent function satisfactorily.

The anti-oxidant additive stabilizes the lubricating oil, imparting a high degree of resistance to oxidation, thus reducing to a minimum the formation of undesirable materials, which make for engine deposits and ultimate wear. Before they can be said to be satisfactory for the lubrication of high-speed oil-engine lubrication, high-quality additive-treated oil blends require to be evaluated under severe, laboratory-controlled engine-test procedures, which correlate with conditions known to exist in fleet operation.

The mixing of selected chemical additives with mineral oils of poor quality does not provide a satisfactory solution for heavy-duty engine-operating conditions. Careful attention must be given to the selection of the base oil, correct matching and the quantity and method of incorporating the additive materials. •

Big operators naturally wish to know how they can determine whether or not such oils are of commercial benefit te them. The answer is to seek the advice of concerns of repute in the oil industry and, if necessary, .earry out properly conducted engine tests under fleetoperating conditions.

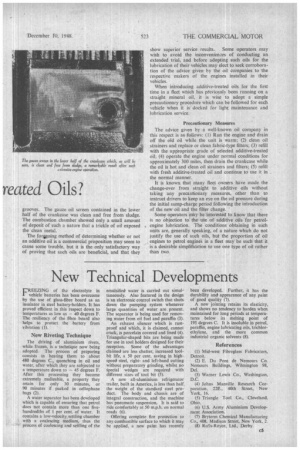

c4 What this means may be deduced,from the results obtained with a Gardner 5LW engine fitted to a Leyland TD.1 double-deck bus, using a well-known high-quality additive-treated oil. Before the photographs here reproduced were taken, the engine hki been essentially undisturbed for a road mileage of 41,654. except for the removal of the cylinder head for normal valve inspection and servicing after approximately 20,000 miles.

Oil consumption was at the rate of a gallon for 900 miles, which included sump drainage at every 5,000 miles.

The accompanying illustrations clearly reveal the small amount of dust-like carbon on the piston crown, and it can be seen that all the rings were free in their grooves. The gauze oil screen contained in the lower half of the crankcase was clean and free from sludge. The combustion chamber showed only a small amount of deposit of such a nature that a trickle of oil exposed the clean metal.

The foregoing method of determining whether or not an additive oil is a commercial proposition may seem to cause some trouble, but it is the only satisfactory way of proving that such oils are beneficial, and that they show superior service results. Some operators may wish to avoid the inconveniences of conducting an extended trial, and before adopting such oils for the lubrication of their vehicles may elect to seek corroboration of the advice given by the oil companies to the respective makers of the engines installed in their vehicles.

When introducing additive-treated oils for the first time in a fleet which has previously been running on a straight mineral oil, it is wise to adopt a simple precautionary procedure which can be followed for each vehicle when it is docked for light maintenance and lubrication service.

Precautionary Measures The advice given by a well-known oil company in this respect is as follows: (I) Run the engine and drain off the old oil while the unit is warm; (2) clean oil strainers and replace or clean fabric-type filters; (3) refill with the appropriate grade of selected additive-treated oil; (4) operate the engine under normal conditions for approximately 300 miles, then drain the crankcase while the oil is hot and clean oil strainers and filters; (5) refill with fresh additive-treated oil and continue to use it in the normal manner.

It is known, that many fleet owners have made the change-over from straight to additive oils without taking any precautionary measures, other than to instruct drivers to keep an eye on the oil pressure during the initial sump-charge period following the introduction of the new oil and the filter change. '

Some operators inky be interested to know that there is no Objection to the use of additive oils for petrol . engine lubrication. The conditions obtaining in such units are, generally speaking, of a nature which do not justify the use of such oils, but the proportion of oil engines to petrol engine's in a fleet may be such that it is a desirable simplification to use one type of oil rather than two.