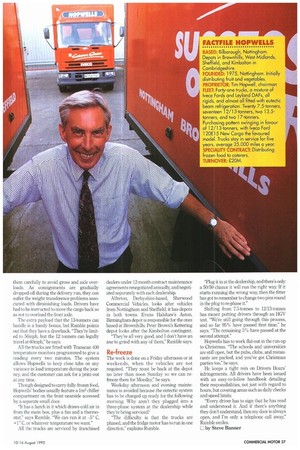

Nottingham reefer specialist Hopwells has found 7.5 tonners inadequate for

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

its multi-drop catering service, so is trading up to 12 tonners. Transport manager, Ted Ramble, explains why.

through look a Hopwells' brochure on an empty stomach; especially if you're on a diet. Its tempting array of burgers, pies and puds—check out the crunchy toffee and banana charlotte— will prompt you to raid the fridge immediately.

Nottingham-based. Hopwells distributes refrigerated frozen food to caterers and suppliers supplying school, university and hospital kitchens. It also delivers to outlets such as cafes and clubs.

The average size of each drop, plus the difficulty of manoeuvring large trucks in and out of Victorian schoolyards, has meant that Hopwells has traditionally relied heavily on 7.5-tonners.

But they're gradually being swapped for 12 and 13-tonners, says transport manager, Ted Ramble.

"We favour eutectic beams for refrigeration, and so we pay a payload penalty which makes 7.5-tonners too small," he explains. "We've found that the Iveco Ford New Cargo at 12 tonnes is the ideal vehicle.

"We're in the process of selling seven 7.5tonners, and replacing them with 12-tonners. So come 1 September, we'll be running a total of 24-120E15 and 130E157E18 New Cargos.

"That'll leave us with thirteen 7.5-tonners, a mixture of Leyland Daf 45 Series and New Cargo 75E15 models. Two 13-tonners have got 180bhp engines, but the rest have got the same 150bhp engine as the 7.5-tonnersthe power output is more than adequate."

Ramble spent over three decades in the motor trade until four years ago, he switched careers and became a transport manager. For much of that time he was involved with Ford, Iveco and Iveco Ford products.

So has that made him favour New Cargo unduly? Not at all, ht replies; he treats every product firmly on its merits.

"The trouble is that Leyland Daf's 12-tonner is on a Freighter chassis, and that's just too big for us," Ramble explains. "But if Leyland Daf ever makes the export-only 55 model available in the UK, we'll be prepared to look at it.

"And if we were buying another load of 7.5tonners, we'd certainly look at Leyland Daf 45 Series."

Switch stock

Ramble does in fact run four Freighters— two at 17 tonnes, two at 13.5 tonnes—but they're used to switch stock between Hopwells' depots overnight. They also collect goods from big cold stores operated by companies such as Christian Salvesen, and are only occasionally used on multi-drop work.

"Apart from three of the 7.5-tonners, the Freighters are the only trucks we have with conventional blower 'fridge units because we use them day and night," he says.

If eutectic beams were fitted, there wouldn't be enough time to refreeze them fully. All the other vehicles are equipped with Hubbard Polarpac eutectic packages.

"Plug them into a three-phase electrical connection, and from an ambient temperature, they will take 10 to 12 hours to pull down to -30'C,"

Ramble says. "All the driver has to do is unplug it and go.

"If he leaves one of our depots at 6.30am, and comes back at 3.30pm—which is quite typical—he can do 35 to 40 drops. That's 35 to 40 rear door openings, in other words, and the truck will still come back at -15°C. Then all he does is plug it back in again. It's as easy as that, and the cost of maintenance is virtually nil.

"Remember that with a blower, the temperature falls every time you open the back doors, and you have to drive quite some distance to build it up again," Ramble continues. "But with eutectics, a level of cold air descends from the roof when the door is opened, and keeps the load cool."

These advantages mean that Hopwells is quite willing to shoulder the weight penalty the beams impose. "Over and above the normal blower system, it's about 200kg on a 7.5tonner, and 580kg on a 12-tonner," he says.

This makes for a 5.5 tonne payload at 12 tonnes gross, and a 6.2 tonne payload at 13 tonnes. "That's ample for us," Ramble comments.

The 7.5-tonners will only carry just over 2 tonnes, however, and Hopwells has to load

them carefully to avoid gross and axle overloads. As consignments are gradually dropped off during the delivery run, they can suffer the weight transference problems associated with diminishing loads. Drivers have had to be instructed to move the cargo back so as not to overload the front axle.

The extra payload that the 13-tonners can handle is a handy bonus, but Ramble points out that they have a drawback. "They're limited to 56mph, but the 12 tonners can legally travel at 60mph," he says.

All the trucks are fitted with Transcan 400 temperature monitors programmed to give a reading every two minutes. The system allows Hopwells to keep close tabs on any variance in load temperature during the journey, and the customer can ask for a print-out at any time.

Though designed to carry fully-frozen food, Hopwells' bodies usually feature a 1m2 chiller compartment on the front nearside accessed by a separate small door.

"It has a hatch in it which draws cold air in from the main box, plus a fan and a thermostat." says Ramble. "We can run it at —5° C, +1° C, or whatever temperature we want."

All the trucks are serviced by franchised dealers under 12-month contract maintenance agreements renegotiated annually, and negotiated separately with each dealership.

Alfreton, Derbyshire-based, Sherwood Commercial Vehicles, looks after vehicles from Nottingham and Sheffield; it has depots in both towns. Evans Halshaw's Aston, Birmingham depot is responsible for the ones based at Brownhills. Peter Brown's Kettering depot looks after the Kimbolton contingent.

"They're all very good, and I don't have an axe to grind with any of them," Ramble says.

Re-freeze

The work is done on a Friday afternoon or at weekends, when the vehicles are not required. "They must be back at the depot no later than noon Sunday so we can refreeze them for Monday" he says.

Weekday afternoon and evening maintenance is avoided because the eutectic system has to be charged up ready for the following morning. Why aren't they plugged into a three-phase system at the dealership while they're being serviced?

"The difficulty is that the trucks are phased, and the fridge motor has to run in one direction," explains Rumble. "Plug it in at the dealership, and there's only a 50/50 chance it will run the right way. If it starts running the wrong way, then the fitter has got to remember to change two pins round in the plug to re-phase it."

Shifting from 7.5-tonnes to 12/13-tonnes has meant putting drivers through an HGV test. 'We're still going through this process, and so far 95% have passed first time," he says. "The remaining 5% have passed at the second attempt."

Hopwells has to work fiat-out in the rim-up to Christmas. "The schools and universities are still open, but the pubs, clubs, and restaurants are packed, and you've got Christmas parties too," he says.

He keeps a tight rein on Drivers Hours' infringements. All drivers have been issued with an easy-to-follow handbook detailing their responsibilities, not just with regard to hours, but covering areas such as daily checks and speed limits.

"Every driver has to sign that he has read and understood it. And if there's anything they don't understand, then my door is always open, and I'm only a telephone call away" Ramble smiles.

by Steve Banner