A NEW BRITISH HIGH-SI ) PASSENGER CHASSIS.

Page 16

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

First Published Particulars of the Latest Pr of Which are a Frame Height of 2 fe■

from the Star Works, the Leading Features a New Engine Developing 45 b.h.p.

IS now being fully recognized by our leading makers that the requirements of the passenger-carrying industry, so far as chassis are concerned, are quite different from those of only a few years ago. There is a strong demand for chassis suitable for carrying neat 20-seater bodies either of the small saloon-bus or coach type, and such vehicles must be capable of maintaining comparatively high average speeds in parts of the country where the population is thinly distributed, so that although the ratio of passengers to mileage may not be high, that of passengers to ruining time is increased.

It is of little use endeavouring to meet such needs by the provision of chassis originally designed mainly for the transport of goods. The reverse does not quite hold good, because a chassis built for passenger work can often satisfactorily be employed for carrying goods where high-speed delivery work is essential.

In this connection the Star Engineering Co., Ltd. who have won a very favourable reputation amongst commercial users for the quality of their products and whose light vans are now being extensively employed by ' the Evening News, Selfridge and Co., Ltd., and other important users, have brought out an entirely new passenger chassis of the low load-line type. In the frame of this chassis the side members are arched over the rear axle, but only to such an extent and width as barely to interfere with the seating, this interference being still further reduced by employing a frame which is inswept slightly at the front and is very wide along the rest of its length, thus bringing the upswept portions fairly close to the wheel arches.

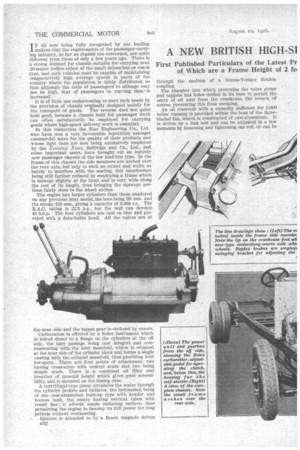

The engine has larger cylinders than those employed on any previous Star model, the bore being 95 mm. and the stroke 120 mm., giving a capacity of 3,406 c.c. The R.A.C. rating is 22.3 h.p., but the unit can develop 45 b.h.p. The four cylinders are cast en bloc and provided with a detachable head. All the valves are at the near side and the tappet gear is enclosed by covers.

Carburation is effected by a Solex instrument which is bolted direct to a flange on the cylinders at the off side, the inlet passage being cast integral and cornmunicating with the inlet manifold, which is situated at the near side of the cylinder block and forms a single casting with the exhaust manifold, thus providing four hot-spots. There are four points of attachment, two having cross-arms with central studs and two being simple studs. There is a combined oil filler and breather of unusual height which gives good accessibility and is mounted on the timing case.

A centrifugal-type pump circulates the water through the cylinder jackets and radiator, the last-named being of the cast-aluminium built-up type with header and bottom tank, the.: centre having vertical tubes with round fins;, it affords ample radiating surface, thus permitting the engine to 'develop its full power for long periods without overheating.

Ignition is attended to by a Bosch magneto driven B32

through the medium of a Simms-Vernier flexible coupling.

The chamber into which protrudes the valve stems and tappets has holes drilled in its base to permit the entry of oil mist from the crankcase, the covers, of course, preventing this from escaping.

An oil reservoir with a capacity sufficient for 5,000 miles' running is provided within the boss of the threebladed fan, which is constructed of cast-aluminium. It is driven by a link belt and can be adjusted in a few moments by loosening and tightening one nut, or can be removed as a whole by loosening one nut and removing the other which holds the swinging bracket supporting the fan spindle.

Provision is made for mounting and driving a dynamo, and a roller chain is employed for driving the latter, whilst the timing gears are of the helical type with Fabroil camshaft gear. The whole unit is four-point suspended by cast-iron brackets bolted inside the frame channels. On these brackets the crankcase is supported by lips and bolted. The brackets are so arranged that the engine and propeller shaft are in line. Three bearings are employed for the crankshaft, these being lined with white-metal.

The cast-iron pistons are not bushed for the floating gudgeon pins, as nothing better than this material can be found as a bearing surface. The big-ends are also white-metal lined, and each has four bolts.

Circulation of the lubricating oil is effected by a plunger-type pump. There is a direct`kad of oil to all bearings, but this oil is not under pressure, whilst the big-ends and cylinders are lubricated by splash. An unusual feature is that no oil filter is employed ; instead, the oil is sucked from well above the bottom of the sump, and it is claimed that nothing but a large stone could possibly stop the pump from • operating. Star vehicles are exceedingly econornical in their oil requirements, and this new engine is guaranteed to run 1,200 miles to the gallon. A simple oil dipper with upper and lower levels marked clearly upon it is employed.

Accommodation is provided at the side of the flywheel housing for a self-starter, which, when in position, is entirely enclosed and not merely held by a strap of doubtful strength, as is sometimes the case.

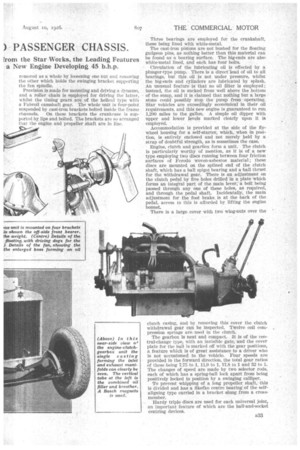

Engine, clutch and gearbox form a unit. The clutch is particularly worthy of mention, as it is of a new type employing two discs running between four friction surfaces of Ferodo woven-asbestos material; these discs are mounted on the splined end of the clutch shaft, which has a ball spigot bearing and a ball thrust for the withdrawal gear. There is an adjustment on the clutch pedal by five holes drilled in a plate which forms an integral part of the main lever; a bolt being passed through any one of these holes, as required, and through the pedal shaft. Incidentally, the main adjustment for the foot brake is at the back of the pedal, access to this is afforded by lifting the engine bonnet.

There is a large cover with two wing-nuts over the

clutch casing, and by remOving this cover the clutch withdrawal gear can be inspected. Twelve coil compression springs are used in the clutch,

The gearbox is neat and Compact. It is of the central-change type, with an invisible gate, and the cover plate for the ball is marked of with the gear positions, a feature which is of great assistance to a driver who is not accustomed to the vehicle. Four speeds are provided in the forward direction, the total gear ratios of these being 7.75 to 1, 11,9 to 1, 17.8 to 1 and n to 1. The changes of speed are made by two selector rods, each of which has a spring-ball lock apart from being positively locked in position by a swinging calliper.

To prevent whipping of a long propeller. shaft, this is divided and has a Skefko centre bearing of the selfaligning type carried in a bracket slung from a crossmember.

Hardy triple discs are used for each universal joint, an important feature of which are the ball-and-socket centring devices. The propeller shafts are tubular, whilst the inverted pot-type axle is a steel stamping of .Kirkstall make, but the gearing for this axle is cut in the. Star works. It is filled with lubricant by means of a plug at the top, whilst an Enots Yubricator is provided for the back bearing of the worm.

Duplex rear brakes, in which four shoes operate in each drum, are employed; these are non-compensated.

The driving dogs are splined on to the differential shafts, which can be withdrawn to permit the worm anti differential gearing to be dropped out of the axle casing. Hotchkiss drive is used and Woodhead springs are fitted throughout, these being long and exceptionally supple.

A worm and complete wheel permit four wearing positions of this steering gear, which should thus have a very long life. Incidentally, all levers, universal-joint spiders and certain other important parts are steel stampings.

Pressed-steel disc wheels of Dunlop make, with 32-in. by 6-in, pneumatic tyres (singles at the front and twins at the rear), are fitted as standard.

The actual upsweep in the frame side-members is approximately 5 ins. The frame has four channel-steel cross-members, the front one being dropped to carry the bracket for the starting handle; the latter is retained in the upright position automatically by a pin on its shaft, which engages with a slot in its bracket.

The centre bearing of the propeller shaft and that for the brake cross-shaft are both lubricated from one nipple mounted at the near side of the frame, the pipe leading from this being forked.

Special nickel-steel is the material used for the valves, and we have learnt of one engine which has run. 44,500 miles without it once being necessary to remove the tappet cover ; as a matter of fact, no other adjustments at all were required.

Petrol is supplied to the carburetter by gravity from an 11-gallon tank mounted on the dash.

We have not yet alluded to the front axle. This is an H-section stamping dropped to permit the low frame level, and its wheels are carried on large taper-roller bearings. Ball joints .are used on the rod between the steering drop arm and that on the stub axle, whilst pin joints with a large bearing area are used in. the case of the track rod, which, in this chassis, is at thg front of the axle.

The main dimensions of the chassis are as follow :—Wheelbase, 12 ft. 4 ins.; track, 5 ft. 1 in.; dash to end of frame, 14 ft. 4 ins.; maximum frame width, 3 ft. in. ; overall length, 18 ft. 442 ins. The chassis price is 1490. The extra cost for a 12-volt five-lamp lighting set is F25, and a similar charge is made if front-wheel brakes are to be fitted.

The Star is one of the most simple chassis which we have examined. At the same time, nowhere are there any signs of skimping, for, considering the work for which it is designed, the strength is ample. We have already alluded to the simple method of taking up wear on the foot brake, but, in addition to this, and to permit proper balancing of the braking effort, large hand-operated adjusting screws of bronze are provided for the side rods controlling the individual shoes.

We were afforded an opportunity for a short run oa on of these chassis, which, in this instance, was equipped with a platform body having chain sides designed for carrying churns of milk. This has been built for a user who was greatly impressed by the fine appearance and good design of the chassis, and for such work it is capable of carrying 2-ton loads.

The test was a somewhat drastic one from the point of view of comfort, as there was no load with the exception of two persons, but the springing proved so good that, although as an experiment we actually sat on the bare boxes over the wheel arches, this was done without discomfort, although speeds up to 40 m.p.h. were attained. The engine proved to be exceptionally powerful, full of life and gave a rapid acceleration; at the same time, it was quiet and caused little vibration even at high speeds. The braking power also proved most adequate.