BROTHERS

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

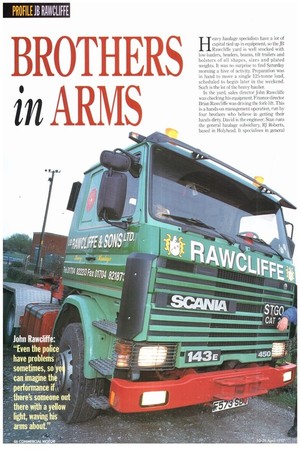

in ARMS Heavy haulage specialists have a lot of capital tied up in equipment, so the JB Rawcliffe yard is well stocked with low-loaders, headers, beams, tilt trailers and bolsters of all shapes, sizes and plated weights. It was no surprise to find Saturday morning a hive of activity. Preparation was in hand to move a single 125-tonne load, scheduled to begin later in the weekend. Such is the lot of the heavy haulier.

In the yard, sales director John Rawcliffe was checking his equipment. Finance director Brian Rawcliffe was driving the fork-lift. This is a hands-on management operation, run by four brothers who believe in getting their hands dirty. David is the engineer; Stan runs the general haulage subsidiary, RJ Roberts, based in Holyhead. It specialises in general haulage traffic to and from Ireland. JB Rawcliffe's latest project was to move an industrial oxidiser for a fabrication company The company first became involved about 18 months ago. Like much work in this sector, it's a time-consuming job. "It's eventually going out to Pakistan, but we are just taking it out of Bolton, down to Manchester and through to the Salford Quays. This one is 55 metres high by 5A metres wide before it moves and Salford is the only way out," says John Rawcliffe. High-profile jobs have included moving a wind tunnel in sections for Williams Formula 1 Racing. Future jobs might include sections of a new stand for Lords cricket ground or even delivery of the "Millennium Wheel" to central London in three years' time. This example gives further evidence of the gestation period for many heavy haulage projects. while helping to explain the one-off nature of the business.

Years of dealing with local authorities and police officers, coupled with very meticulous planning and long, drawn-out projects have made John Rawcliffe a patient man. Questions such as 'Won't the narrow streets of London make that one a little bit tricky?' are politely dealt with: "Well, you could float it down the Thames on a barge, I suppose. But then you've still got to work out how you're going to lift it off at the other end and take it by road anyway So far we've only talked it through with the design people. What's clear is that the hub and the axle will have to go in one piece. It's not something that you could assemble on site."

It's all a long way from the first heavy job that the company (founded in 1956) did in 1972. "A local company asked us if we could take a footbridge from Burscough to Cambridge," says Rawcliffe. "We made the bogie ourselves, put a bolster on the tractor and off we went."

While it then became a question of finding other work to keep the new kit employed, the step from general haulier to heavy haulier was made easier thanks to the direction the company had taken since its initial push into the animal feed sector.

"We were involved in a lot of Irish trade, through Preston Docks and then Fleetwood. Industrial development meant there was a great deal of building work and we started taking over the abnormal loads," says Rawcliffe. The Irish connection has continued through the acquisition 12 years ago of RJ Roberts, which runs 14 vehicles and uses a large number of subcontractors on regular crossings of the Irish Sea.

It handles the general haulage traffic, leaving JB Rawcliffe to concentrate on the heavy stuff. Today, the heavy stuff contributes about £3.5m a year, but a significant amount of this is re.invested in equipment. If not built inhouse, it is sourced from Dutch-based manufacturer Noteboom or French company Nicolas. It is very expensive. "Every time you talk to a company like Nicolas about equipment, it's in terms of £50,000-plus," he says. "For example, that trombone-well low-loader came in at Christmas. It can do a lot of loads, has a telescopic bed which goes out to 36 metres and a running height of 4.2m. We can drop that down with the hydraulic suspension. It cost around £85,000 but you can't guarantee work for it all the time."

With expenditure in these terms, encroachment from general hauliers prepared to try their hand—without the correct kit and without paying for a Special Types licence—is an obviously sore point. Apart from the unfair competition there's the legal aspect. "Sometimes you can be driving along and see a wide load and you know immediately that it's not right," says Rawcliffe.

However, the investment cost involved deters many. Consequently, specialists such as Rawcliffe are reluctant to sell off superfluous kit (sometimes made in-house) on the secondhand market. "You've got to be careful who you are selling it to. If you are buying replacement gear at between L70-100,000 and selling old equipment off cheap to someone, that someone could do you a lot of damage." Disposal takes place much further afield. "We have sold two vehicles into India and another two in Indonesia. The owner there still runs them in our colours, but we think it's reasonable to assume that if they've gone that far, they won't be coming back to compete with us," says John Rawcliffe.

The police escort issue has been known to raise the hackles of even the most mild mannered of heavy hauliers, of which John Rawcliffe is surely one. However, as far as he is concerned, the police have costs to cover and if the client wants to move a load, these have to be paid—no argument. Drawn on the subject of privatised escort firms, he is every bit as diplomatic—but a little more animated: "Whether they will work or not I don't know, but only the police can stop the traffic. If people see a blue light they generally pull over. But even the police have problems sometimes, so you can imagine the performance if there's someone out there with a yellow light, waving his arms about."

Specialists

Private or otherwise, heavy hauliers will continue to need escorts. The industrial plant fabrication companies will continue to need heavy haulage specialists, even if most of the jobs are one-offs. More than 25% of the JB Rawcliffe business is derived from 2030 tonne loads, so while there might not be several loads a week, or really big loads all of the time, most of the equipment is busy most of the time.

One potential source of extra business could be the electricity generating companies. Rawcliffe has been involved in feasibility studies concerning replacement of plant at some of the older generating stations. He says the new plant designs are often much bigger, while the width of the feeder roads has often remained unchanged. Haulage equipment design has progressed too, so that steerable trailers allow delivery of replacement plant which is much larger than the original—some of which was delivered over 25 years ago, by pi operators such as J13 Rawcliffe & Sons.

The message is clear. Provided you have the correct kit, give a good service and continue to devise original solutions to some very >1-2 big problems, repeat business does materi alise it's just that in the heavy haulage busi8 ness, everything seems to take longer. _I by Steve McQueen