Successful Normal-contro ripper Design

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

By John F. Moon,

A.M.I.R.T.E.

THE pros and cons of forward control versus normal control for . tipper duty are a constant topic of .discussion among operators. The supporters of forward control claim that this design gives added manceuvrability, better visibility, and other advantages derived from short overall length: The normal-control diehards quote better inter-axle weight distribution—particutarly higher rear-axle loading, which gives additional traction, and the low, front-axle loading, which makes steering easier—better access to the, cab and power unit, and greater overall stability.

The latest normal-control tipper is the -Bedford J6 7-tonner, which is one of a range of normal-control chassis of 25-cwt. to 7-ton capacity intro duced last August.

Hying Colours One of them has been tested by The Commercial Motor, both under normal road conditions and on site work on a section of the LondonYorkshire motorway near Luton. Apart from one or two detail points, the vehicle came through the test with flying colours.

It will be popular with drivers., for the degree of cab comfort provided is close to that normally associated with American vehicles (which is not surprising in view of Vauxhall's American connections), whilst its general handling leaves little to be desired.

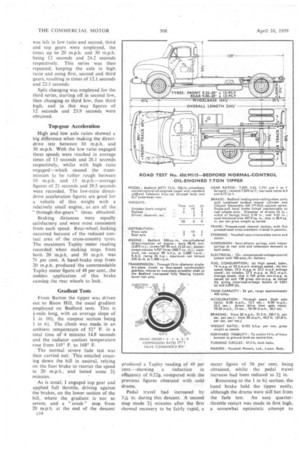

The Bedford J series 7-ton tipper is available with a choice of oil or petrol power units. The oil engine is the Bedford 300-cuAn. unit, which was fitted to the test vehicle. The petrol engine is the 300-cu,-in. "Six," of 133 b.h.p. gross and 114 b.h.p. net. With either engine a 12-in.-diameter clutch is employed and the four-speed synchromesh gearbox is the Bedford wide-ratio unit.

c12 A two-piece propeller shaft takes the drive to the Bedford two-speed rear axle, which is a standard fitting. This axle is offered with ratios of 6.4 and 8.72 to or 5.83 and 7.95 to I, the former set of ratios being recommended when the tipper" is likely to be engaged in a high percentage of oft-the-road work.

. Side members 10 in. deep, pressed from 1-in.-thick mild steel, form the basis of the frame, the side-member flange width being 2.87 in. As opposed to other models in the new Bedford normal-control range, the 7-ton chassis have flat-topped sidemembers, which simplify body mounting and the fitting of tipping gear and so forth, and the frame is, braced by five riveted pressed-steel crossmembers.

Semi-elliptic springs are employed at front and rear. The front springs are 45 in. long and those at the rear are 60 in. long. Helper springs are standard at the rear. Telescopic dampers are fitted as standard to the front axle, and are optional at the rear.

Bedford leading and trailing shoe, brake units, actuated through a Lockheed tandem master cylinder with Clayton Dewandre 5:25-in.-diameter vacuum servo, are fitted at both axles. Moulded facings give a total frictional area of 497.9 sq. in.

'Regular production options, in addition to rear shock absorbers, include a five-speed gearbox which has forward ratios of 7.08, 3.78, 2.24, 1.47 and 1 to 1 (reverse being 7.01 to 1), three-piece wheels, and cab heating and demisting equipment.

Autolift and Telehoist all-steel welded bodies are offered as standard. They have interior lengths of lift. 3 in. and 11 ft. 6 in. respectively, and rated capacities of 6 cu. yd. The interior body height is 2 ft. 13in. Both bodies are available with remote tailboard controls which the driver can operate without leaving the cab.

A Telehoist SL7 double telescopic underbody ram was fitted to the test vehicle. It had a self-contained oil reservoir and valve gear at the bottom of the ram, making for a neat installation. Autolift bodies are supplied with Weston vertical double-extension ram gear and stabilizer,

Mixed Tyres

Road-tread 8.25-20-in. (12-ply) tyres were fitted to the 86.0 X 20 (5.1-in. offset) front wheels, and cross-countrytread 9.00-20-in. (12-ply) twins at the rear on B6.5 x 20 (5.6-in, offset) wheels. The spare wheel also carried a 9.00-20-in. cross-country tyre.

The complete vehicle's kerb weight was 3 tons 191 cwt., the rear-axle load being 2 tons 2+ cwt. It is interesting to compare these figures with the comparable weights of the Bedford S-type forward-control 7-ton tipper. Its kerb weight is 3 tons 121 cwt., but the rearaxle loading is relatively much • lower at 1 ton 114 •cwt., giving the normalcontrol design a clear 10-cwt. advan tage in respect of rear-axle adhesion when empty.

Ballast had been loaded into, the body level with the top of the sides, and a weight check showed that 6 tons 3 cwt. had been added. Thus the gross vehicle weight, with Cohn Prebble, of Vauxhall Motors, and myself in the cab, was 10 tons 6 cwt., a mere 72 lb. over the manufacturer's recommended figure. The rear-axle loading was 7 tons 6+ cwt., giving a relatively low front-axle loading, which was later found to afford excellent steering characteristics.

For the first test, the laden tipper was driven along the A6 road to my usual six-mile undulating consumption course between Barton and Clophill and here two sets of fuel figures were taken. The first was obtained by driving reasonably hard at up to 40 m.p.h. A consumption rate of 16 m.p.g. was obtained at an average speed of 29.4 m.p.h.

The second test was conducted at a maximum speed of a little over 30 m.p.h, (not a practice normally observed by tipper drivers) and this time a consumption rate of 19.2 m.p.g. was returned, the average speed being 25.5 m.p.h.

Three sets of acceleration figures were taken from a standstill to 30 m.p.h. For the first test, the axle was left in low ratio and second, third and top gears were employed, the times up to 20 m.p.h. and 30 m.p.h. being 12 seconds and 24.2 seconds respectively. This series was then repeated, keeping the axle in high ratio and using first, second and third gears, resulting in times of 12.1 seconds and 23.5 seconds.

Split changing was employed for the third series, starting off in second low, then changing to third low, then third high, and in this way figures of 12 seconds and 23.9 seconds were obtained.

Top-gear Acceleration

High arid low axle ratios showed a big difference when making the directdrive test between 10 m.p.h. and 30 m.p.h. With the low ratio engaged these speeds were reached in average times of 13 seconds and 26.1 seconds respectively, whilst with high ratio engaged-which caused the transmission to be rather rough between 10 m.p.h. and 15 m.p.h.-average figures of 21 seconds and 39.5 seconds were recorded. The low-ratio directdrive acceleration figures are good for a vehicle of this weight with a relatively small engine, as are all the " through-the-gears " times obtained.

Braking distances were equally satisfactory and were most consistent from each speed. Rear-wheel_ locking occurred because of the reduced contact area of the cross-country tyres. The maximum Tapley meter reading recorded when making stops from both 20 m.p.h. and 30 m.p.h. was 71 per cent. A hand-brake stop from 20 m.p.h. produced the commendable Tapley meter figure of 48 per cent., the sudden application of this brake causing the rear wheels to lock.

Gradient Tests

From Barton the tipper was driven out to Bison Hill, the usual gradient employed on Bedford tests. This is 1-mile long, with an average slope of 1 in 104-, the steepest section being 1 in 64, The climb was made in an ambient temperature of 52° F. in a total time of 4 minutes 14.8 seconds and the radiator coolant temperature rose from 145° F. to 168° F.

The normal severe fade test was then carried out. This entailed coasting down the hill in neutral, relying on the foot brake to restrict the speed to 20 m.p.h., and lasted some 24 minutes.

As is usual, 1 engaged top gear and applied full throttle, driving against the brakes, on the lower section of the hill, where the gradient is not so severe, and a crash " stop from 20 m.p.h. at the end of the descent c14 produced a Tapley reading of 49 per cent.-showing a reduction in efficiency of 0.22g. compared with the previous figures obtained with cold drums.

Pedal travel had increased by 3A in. during this descent. A second stop made 24 minutes after the first showed recovery to be fairly rapid, a meter figure of 56 per cent. being obtained, whilst the pedal travel increase had been reduced to 24 in.

Returning to the 1 in 64 section, the hand brake held the tipper easily, although the drums were still hot from the fade test. An easy quarterthrottle restart was made in first high, a somewhat optimistic attempt to restart in second low only just failing.

A restart could probably be made in this set of ratios on anything up to 1 in 4+, whilst with the low axle ratio engaged restarts should be possible on gradients of at least 1 in 3-1, which is more than .adequate ,for most tipper operations, both on and off the road.

The load was disposed of in the Whipsnade Zoo area, to the delight of an unsuspecting man who was stopped and asked whether he could use 6. cu. yd. of gravel and realized that it was just what he required for his garage entrance. During unloading it was noted that the tailboard release lock was stiff to operate and that the tipping ram stuck half-way during the lowering of the body. This was freed by jumping the chassis forward.

Rear-wheel Spin

The load was tipped at the top of a slippery slope and it was observed that, even despite the advantageous rear-axle loading, some rear-wheel spin occurred when reversing up the gradient.

Next the unladen vehicle was taken back to the Barton course, where a reasonably high-speed unladen fuelconsumption test returned figures of 27.5 m.p.g. and 30.2 m.p.h. Combination of the two laden and unladen figures obtained during this test would suggest that, neglecting fuel used when tipping, on the site and so forth, an average road consumption rate of about 21 m.p.g. should • be obtained.

At this point it is perhaps appropriate to quote figures taken with this vehicle by Colin Prebble shortly before I tested it. One set Was obtained over a 122-mile run with a

11-ton overload. The consumption rate was 14.8 m.p.g. and the .average speed, 27.6 m.p.h.

A second set of figures was then taken with the vehicle at the weight as tested by me. A trip over a 921mile circuit gave also similar results14.7 m.p.g. and 27.8 m.p.h.—suggesting that the addition of the normal overload experienced in tipper work hardly affects fuel economy at all.

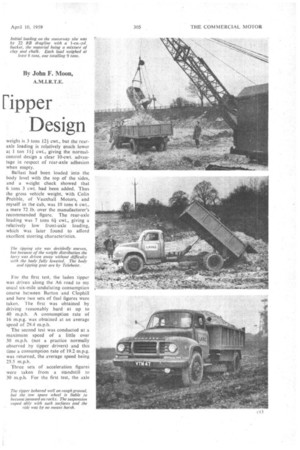

It had been ,arranged with John Laing and Son, Ltd., that the lorry should be worked for half a day on one of the sections of the LondonYorkshire motorway, near Farley Hill inthe Luton area. A wide cutting is being made from ground which consists mainly of chalk and old clay. This was being loaded by a 22 RB drag line with a 1-cu.-yd. bucket, an eight-bucket load weighing in the region of 71-8 tons.

With about 8-Cu. yd. aboard, the Bedford was driven from the excavation site on to the main road—a distance of a quarter of a mile—and

then driven hard to the tip, which was some 2.8 miles away from the site. Additional running at the tip accounted for another half-mile or so and the round trip back to the drag line—an overall distance of 5.8 miles —took just under 30 minutes.

A calibrated fuel test tank was used during this exercise and at the end of the run a reading showed that five pints of fuel had been consumed, giving an overall consumption rate of 9.3 m.p.g. Although this may appear heavy, it must be remembered that nearly 14 minutes were spent waiting in the queue of lorries at the digger with a further four minutes at the tipping site, the actual running time being only about 12 minutes.

This round trip was repeated several times and on one occasion the engine was switched off whenever the opportunity occurred while waiting to be loaded. This is apparently the custom of other drivers at this site when a long wait is foreseen. Although the engine was switched off for some • quarter of an hour of the total trip time of 27 minutes, the amount of fuel used was almost identical. Only under the most favourable conditions would a round figure of 10 m.p.g. be obtained on this sort of work.

The last load was collected from a slightly different part of the site. It was loaded by a 22 RH digger with a 2-cu.-yd. bucket and, against the advice of the digger operator, we asked for five bucket loads to giVe about the same payload as the dragline previously used.

As the vehicle was standing on sticky clay at the time, it is hardly surprising that its rear end sank. The spare wheel, which is slung horizontally under the dear-side frame member, was bogged down and we had to be dragged out of the initial slime by a bulldozer.

Ample Engine Power

Once clear of the heavy ruts, however, the Bedford pulled away happily from the site and a weighbridge check showed that it had been loaded with nine tons of clay and chalk. This was a 50-per-cent. overload in terms of payload capacity. The engine was able to deal with it comfortably and it did not cause instability or signs of inadequate braking.

My only criticism of the vehicle as regards off-the-road work is the vulnerably low spare-wheel mounting. Indeed, the lorry would be better off without a spare wheel if some alternative position cannot be found for it. Not only is it liable to stop forward motion under severe conditions, but it is susceptible to damage from rocks.

There is also the inconvenience of clamping bolts becoming clogged with mud.

Both on and off the road the tipper handled superbly. The steering was first class: it was light to operate, without any trace of wander and with a useful degree of castor action. The steering wheel requires seven turns to take the wheels from lock to lock, but this did not seem to be a disadvantage.

The lorry rode well on normal road surfaces, both with and without load, and although the engine idling is a little rough, the degree of engine noise penetrating the cab was commendably low. The engine pulls well in all gears, having a lively top-gear performance, and the overall spread of gear ratios is well suited to the engine characteristics, as, of course, it should be with an engine, gearbox and two-speed rear axle all made by the chassis manufacturers.

Comfortable Cab The cab gives a high degree of driving comfort. The wide, deep onepiece windscreen, affords good forward vision, but also_ creates a false impres'sion of speed. Frequently, when I was driving at what I thought was 30 m.p.h. the speedometer showed 40 m.p.h., whilst the maximum speed of 50 m.p.h. did not really seem at all .fast.

All the controls are well placed. A slight criticism is that none of the instrument-panel knobs is labelled and a driver unfamiliar with the vehicle could get into difficulties in operating the lights, stopping the engine and so forth.

Time did not allow maintenancetasks to be conducted, so one of the principal advantages of normal-control —good engine accessibility—could not be put to the test. Visual inspection, however, revealed that all the underbonnet units and accessories were easy to reach, whilst maintenance of the rest of the chassis should follow normal Bedford practice.

The Bedford J6ST1 12-ft. l0--in.wheelbase normal-control tipper, with Bedford 300-cu.-in, oil engine, has a basic chassis price of £1,120, plus £257 18s. 3d. purchase tax. The standard cab adds a further £75 to the standard price. The complete tipper as tested has a basic price of £1,440, plus £257 18s. 3d. purchase tax.

Additional equipment fitted to the test vehicle included telescopic dampers at the rear axle (£6 17s. 6d. including tax) and 9.00-20-in. (1'2-ply) rear andspare tyres (£38 6s. 10d. including tax) The equivalent tipper with Bedford six-cylindered petrol engine has a basic price of £1,315, plus £226 13s. 3d. purchase tax.