BEDFORD

Page 70

Page 71

Page 72

Page 73

If you've noticed an error in this article please click here to report it so we can fix it.

NECENT Comfort for Driver

Bedford Forward-control Goodsvehicle Range Now Completely Redesigned: New TK Models Have Set-back Engines to Improve Driving Comfort and Power-unit Accessibility

OUTSTANDING cab design distinguishes the new Bedford TK series of forward-control goods chassis announced on Tuesday. Careful thought has ensured maximum comfort for driver and passenger and an acceptable degree of accessibility to the engine, located beneath the seats, without encroaching to any marked degree on the body space available with the earlier S and TC types which these new models supersede.

The driver sits well forward, so he has a clear view of the road. Entrance

steps ahead of the front axle and the low floor ensured by the use of 16-in.diameter wheels on 3-, 4-, and 5-ton models make the cab effortless to climb into and out of.

Although many of the mechanical components used in the TK models are similar to those previously employed in the S and TC series, major changes have been made in the braking systems. Transmission hand brakes are employed on all models and air-hydraulic systems are used on oil-engined chassis (with the option of vacuum assistance on tractive units only), whilst all petrol-engined chassis have vacuum-hydraulic braking as standard.

The new range not only supersedes previous Bedford forward-control models

(of which more than 80,000 were made in 10 years), but also extends the range available. Whereas previously there were only 5-, 6-, 64and 7-ton chassis, available with oil or petrol engines, the TK series includes 3and 4-ton models on 16-in. wheels and—at the other end of the range—a 71-ton chassis offered as a normal load carrier, a tipper or a 12ton tractive unit.

Prices are only slightly higher than those of the earlier forward-control vehicles, but represent even better value for money.

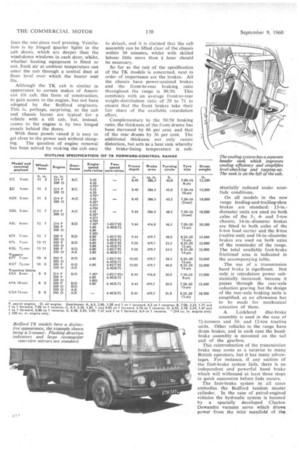

There are 13 basic models in the new range, including two short-wheelbase tippers and three tractive units with wheelbases of 8 ft. All models are available with oil or petrol engines, the Bedford 214-cu.-in and 300-cu.-in. petrol engines, 200-cu.-in. and 300-cu.-in oil engines and Leyland 0.350 oil engine being offered according to the size of the chassis.

Transmission Options

The availability of these units is indicated in the accompanying table, from which it will be seen also that there is a choice of gearboxes, including fourand five-speed units, throughout the range. Bedford-built two-speed axles are offered as optional equipment on chassis of over 6-ton capacity, except in the case of the KGA 12-ton tractive unit, for which the two-speed axle is mandatory.

Although the cab looks much longer and bulkier than the S-type, it is only 2.7 in. longer, the whole of the increased length lying behind the front-axle centre line, so that the front overhang is unchanged.

The cab is of all-steel welded construction, with integral steel underframing, mounted at four points on the

chassis frame. Although the engine lies beneath the seats, the cab itself has a lower overall height than that of an type, there there being a difference of some 4 in. in the case of models having comparable wheels and tyres.

Seat back squabs lie almost directly

above the front-axle centre line. This leaves a space about 2 ft. long between them and the rear panel of the cab, which provides room above the engine for an air cleaner and gives useful stowage space for tools and ancillary electrical equipment.

This compartment is enclosed at the top by a flat panel which forms a useful shelf for driver's personal effects. It also enables the overall glazed area of the cab to be increased, because fixed lights are incorporated in the sides of the cab behind the doors.

The. cab floor ahead of the seats is completely flat, so that the driver can reach his seat quite easily from each side. Instead of a steering-column gear lever, with greatly increased complication in linkages, a short lever is mounted on top of the engine cowling between the driver's and mate's seats, where the driver can reach it with the minimum of effort. Similarly, the hand brake has been kept out of-the way of the floor space by mounting it on the seat box to the right of the driver's seat. The lever assembly is short and similar to that at one time employed on certain Vauxhall cars. It has been possible to make the control short because the use of a transmission brake, the effect of which is multiplied by the rear-axle gearing, avoids the need for high leverage.

The driver's knees are on roughly the same level as the base of the one-piece curved windscreen and he is able to see within 7 ft. of the front of the cab at ground level. As the windscreen is deep, its top is unlikely to be below the level of the driver's eyes. Some of the largest windscreen-wiper blades to be used in this country have been adopted to ensure good vision in rain or snow.

Because the driver sits ahead of, and above, the power unit, he hears remarkably little noise. The cab is cool for the same reason, so provision has been made for fitting a fresh-air heating system which directs air into the cab at floor level.

Insulation material to keep out both noise and heat is used beneath the _engine cowl., floor and front panel, and

lines the one-piece roof pressing. Ventilation is by hinged quarter lights in the cab doors, which are deeper than the wind-down windows in each door, whilst, whether heating equipment is fitted or not, fresh air at ambient temperature can enter the cab through a central duct at floor level over which the heater unit fits.

Although the TK cab is similar in appearance to certain makes of American tilt cab, this form of construction, to gain access to the engine, has not been adopted by the Bedford engineers. This is, perhaps, surprising, as the cab and chassis layout are typical for a vehicle with a tilt cab, but, instead, access to the engine is by two hinged panels behind the doors.

With these panels raised it is easy to get close to the power unit without stoop ing. The question of engine removal has been solved by making the cab easy to detach, and it is claimed that the cab assembly can be lifted clear of the chassis within 30 minutes, whilst with skilled labour little more than hour should be necessary.

So far as the rest of the specification of the TK models is concerned, next in order of importance are the brakes. All the chassis have power-assisted brakes and the front-to-rear braking ratio throughout the range is 50:50. This combines with an average front-to-rear weight-distribution ratio of 29 to 71 to ensure that the front brakes take their fair share of the available retardation effort.

Complementary to the 50:50 braking ratio, the thickness of the front drums has been increased by 66 per cent. and that of the rear drums by 36 per cent. The additional thickness not only resists distortion, but acts as a heat sink whereby the brake-lining temperature is sub stantially reduced under nearfade conditions.

On all models in the new range leading-and-trailing-shoe brakes are standard: 13-in.diameter units are used on both axles of the 3-, 4and 5-ton chassis; 14-in.-diameter brakes are fitted to both axles of the 6-ton load carrier and the 8-ton tractive unit; and I6-in.-diameter brakes are used on both axles of the remainder of the range. The total available foot-brake frictional area is indicated in the accompanying table.

The use of a transmission hand brake is significant. Not only is retardation power substantially increased, because it passes through the rear-axle reduction gearing, but the design of the rear-axle braking units is simplified, as no allowance has to be made for mechanical actuation of them.

A Lockheed disc-brake assembly is used in the case of

71-tonners and 10and 12-ton tractive units. Other vehicles in the range have drum brakes, and in each case the handbrake assembly is mounted on the tail end of the gearbox.

This reintroduction of the transmission brake may come as a surprise to many British operators, but it has many advantages. For instance, if any section of the foot-brake system fails, there is an independent and powerful hand brake which will withstand at least three stops in quick succession before fade occurs.

The foot-brake system in all cases embodies the Bedford tandem master cylinder. In the case of petrol-engined vehicles the hydraulic system is boosted by a specially developed Clayton Dewandre vacuum servo witieh draws power from the inlet manifold of the

engine. This is standard throughout the petrol-engined models.

Oil-engined chassis have an air servo as standard, for which purpose a singlecylindered compressor is mounted on the engine. The only exception to this rule applies in the case of oil-engined tractive units when required for operation with vacuum-braked semi-trailers. Then the compressor is replaced by an exhauster.

The manufacturers claim that pedal effort is reduced by 30 per cent. in the case of the vacuum-hydraulic system and by 50 per cent. when air assistance is employed, compared with the pedal pressures required with former Bedford forward-control chassis.

Another small but significant change in the braking systems is the replacement of the (Ad type of Beslford "fingertip" adjusters by a new version which permits external adjustment of the brakes by means of a spanner. In this respect the elimination of a mechanical linkage to the rear brakes from the hand-brake lever has been of particular advantage.

Close attention has been paid to general suspension arrangements, and long ftont springs are used on all models, varying in length from 45 in. on the lighter vehicles to 53+ in. in the case of the heavier chassis. Leaves 3 in, wide replace the former 2f-in.-wide leaves, and suspension damping at the front axle has been improved by increasing the effective diameters of the telescopic dampers from 1 in. to 11 in.

New rear springs are employed on certain models, and in all cases new rear hanger brackets have been incorporated. Telescopic dampers are standard equipment on tippers and optional on others. All TK chassis have frames which are flat-topped rearwards from the back of the cab, and cold-squeeze-riveting is employed throughout. Improved pedestal mountings are used with 14-ft. and 16ft-long factory-built bodies. All 18-ft.long bodies are mounted on full-length timber longitudinal members.

Steel-cord tyres are standard on both types of 5-ton chassis, and are available as optional equipment on the 4and 6ton chassis. Without the use of such tyres it would have been almost impossible to specify 16-in.-diameter wheels for the 5-tonner. The small-diameter tyres bring the loading height down to

BUMPER TO BACK OF CAB \ MODEL TK 72-9" MOBEL S

421 in. in the case of the 5-tonner and 411 in. on the 3-tonners and 4-tonners.

Another innovation is the, offer of 17in-diameter wheels as optional equipment on 6-ton models. These reduce loading height by l in. when compared with a. 6-tonner equipped with 20-in.-diameter wheels. All models in the range have the. latest Bedford "square blank" wheels, which, because of the absence of rivets, are claimed to have a longer life and greater freedom from distortion.

All the engines employed in the new range are basically similar to those formerly offered in Sand TC-series forward-control models and currently available in TJ-series normal-control chassis.

New crankcases have been required for the 200-cu.-in, oil engines and 300cu.-in. petrol and oil engines. Other modifications mainly affect clutch housings. In all cases the cooling systems incorporate a new design of radiator, which is placed immediately ahead of the engine. Cooling efficiency and accessibility for topping-up are promoted by the provision of separate header tanks.

Three-point mountings for the enginegearbox units have been retained, but the rear mounting is completely new. Swinging links fitted directly to the clutch housing replace the trunnion mounting.

Certain of the axles used in the new range are common to TJ models, but higher loading capacities have been achieved by increasing the thicknesses of the axle tubes and by the use of highercapacity bearings. A new single-speed hypoid-bevel axle, rated at 18,000 lb, is offered for the KGL 7-1-tonner.

The SE passenger chassis and R-type 4 x 4 goods chassis remain in production unchanged, as do the TJ normalcontrol goods models.