Two New Spring-damping Devices

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

for Light Vehicles

TINE of the great difficulties which is ILJ experienced in connection with light vehicles, so far as their suspension is concerned, is that of checking axle

bound, thus causing smoother riding. The Armstrong's Patents Co., Ltd., Eastgate, Beverley, East Yorkshire, has for some time been manufacturing spring-damping devices for ears. This company now informs us that it is marketing pattern.; suitable for commercial vehicles carrying up to 30 cwt.

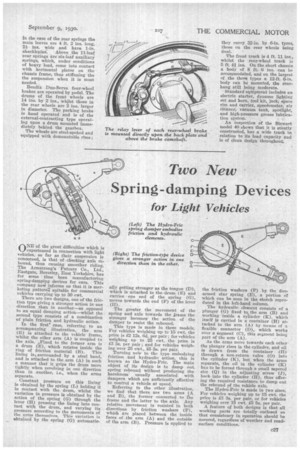

There are two designs, one of the friction type giving a stronger action in one direction than in another—as opposed to an equal damping action—whilst the second type consists of a combination of plain friction and hydraulic action.

In the first case, referring to an accompanying illustration, the arm (R) is attached to the vehicle frame, whilst the other arm (A) is coupled to the axle. Fixed to the former arm is a drum (E), which rotates inside the

ring of friction material (B). This lining iskeurrounded by a steel band, and is attached to the arm (A) in such a manner that it grips the drum more tightly when revolving in one direction than in another, i.e., when the arms separate.

Constant pressure on this lining is obtained by the spring (L) holding it in contact with the drum, whilst the variation in pressure is obtained by the action of the spring (G) through the lever (H) pressing the lining into contact with the drum, and varying its pressure according to the movements of the arms themselves. ¶i'hig variation is obtained by the spring (Cl) automatic

ally getting stronger as the tongue (D), which is attached to the.drum (E) and carries one end of the spring (G), moves towards the end (F) of the lever (II). .

The greater the movement of the spring and axle towards the Penne the stronger becomes the action of the damper to resist the rebound.

This type is made in three models. . For vehicles weighing up to 15 cwt. the price is 12 12s. 6d. per pair ; for vehicles weighing up to 25 cwt. the price is £3 3s. per pair ; and for vehicles weighing over 25 cwt., 15 5s. per pair.

Turning noire to the type embodying friction and hydraulic action, this is known as the Hydro-Eric. The main object of its design is to damp out spring rebound without producing the harshness' usually associated with dampers which are sufficiently effective to control a vehicle at speed.

Referring to the other illustration, we find that there are two arms (A and B), the former connected to the frame and the latter to the axle. Any relative movement is resisted in both directions by friction washers (F), which are placed between the inside faces of the arm (A) and the outside of the arm (B). Pressure is applied to the friction washers (F) by the fivearmed star spring (E), a portion of which can be seen in the sketch reproduced in the left-hand column.

The hydraulic element consists of a plunger (G) fixed to the arm (B) and working inside a cylinder (K), which itself is carried in a container (H) attached to the arm (A) by means of a flexible connector (D), which works over .a segment (C), this segment being part of the arm (A).

As the arms move towards each other the plunger rises in the cylinder, and oil is drawn from the container (H) through a non-return valve (0) into the cylinder (K), but when the arms separate, the oil in the cylinder (IQ has to be forced through a small tapered slot (Q) in the adjusting screw (T), back into the cylinder (H), thus offering the required resistance to damp out the rebound of the vehicle axle.

The HydreeFric is made in two sizes. For vehicles weighing up to 15 cwt. the price is £3 3s. per pair, or for vehicles weighing over 15 cwt. 15 5s. per pair.

A feature a both designs is that all working parts' are totally enclosed so that consistency in operation should he assured, regardless of weather and roadsurface conditions.