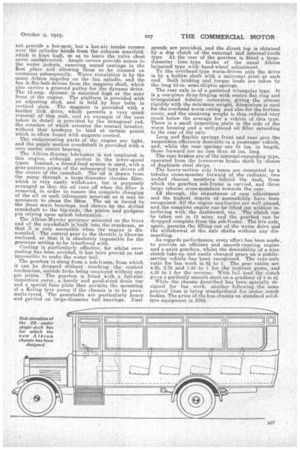

A NEW ALBION BUS CHASSIS

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

Designed to Accommodate Bodies Seating 20 Passengers, this Chassis Has Many New and Original Features.

THE Albion Motor Car Co., Ltd., are evidently. determined to cater for the widest possible market with their latest range of models with which we have recently been dealing.

In a recent issue we dealt with the new 32 h.p. Mark II model, embodying a detachable-head engine, and we mentioned that a chassis specially designed for bus work was also to be marketed. This we are now able to deal with in detail, and it will be found an interesting addition to the production range of the well-known Scottish manufacturing company. • The chassis is primarily intended for the saloon type of bus body to seat 20 passengers. With a wheel base of lilt. 9 ins., the design gives an overall length of N ft. and a width of 7 ft. 2 ins. The overall height is 8 ft. 9 ins., and the interior height on the centre • line gives 6 ft. 10 ins, of headroom. The cross seats are 2 ft. 8 ins, in length and leave a centre gangway of 1 ft. 4 ins., thus providing a very useful type of single-deck bus capable of a good turn of speed and having a low petrol consumption. This model is standardized with super-cushion front tyres and twin solids on the rear wheels, when a speed of 20 m.p.h. is possible before the governor comes into action. With pneumatic tyres the maximum speed is raised to about 21i m.p.h. Arrangements are made for some five alternative tyre equipments for both front and rear wheels. Users of motor vehicles have, therefore, a wide selection from which to meet their individual requirements.

Departures from Albion Practice.

The chassis in its general appearance is on typical Albion lines, but despite its sturdy design the chassis weight with tanks empty is only 34 cwt. Examination, however, reveals a number of departures from older Albion practice. Thus the engine is of new design, with detachable heads and force B36

feed lubrication by gear-type pump, the four-speed gearbox is' of the sliding type, there is a clutch brake on the clutch shaft and there is a new design of rear axle. The bore and stroke of the engine are ai ins. and 5 ins., or, expressed in millimetres, approximately. 98 mm. and. 127 mm. The R.A.C. rating is 24 h.p.,

and the full power.. i .eutput for bus work s attained at 1,300 revolutions. The four cylinders form a monobloc casting, with a detachable head for each pair of cylinders, rendered gas and watertight by gaskets and rubber rings, as in the case of the 32 h.p. engine. The carburation system in this case does

not provide a hot-spots but a hot-air intake crosses over the cylinder heads from the exhaust manifold, which is kept high, so as to leave the valve chest cover unobstructed. Ample covers provide access to the water jackets, ensuring &mind castings in the First place and allowing theni to be cleaned on occasions subsequently. Water circulation is by the usual Albion impeller on the fan spindle, and. the fan is flat-belt-driven from the magneto shaft, which also carries a grooved pulley for the dynamo drive. The 12-amp. dynamo is mounted high at the near front of the engine. The platform is provided with an adjusting stud, and is held by four bolts in vertical slots. The magneto is provided with a leather link drive, which permits a very quick removal of this unit, and an example of the care taken in detail is provided by the hexagonal rod, the rotation of which actuates the contact breaker, without that tendency to bind at certain points which is often found with magneto control.

The reciprocating parts of the engine are light, and the ample section crankshaft is provided with a very useful centre bearing.

The Albion-Murray lubricator is not employed in this engine, although perfect in the lower-speed types. Instead,-a forced-feed system is used, with a. gear-pattern pump of the submerged type driven off the centre of the camshaft. The oil is drawn from the sump through a large-sliameter circular filter, which is very easily withdrawn, but is purposely arranged so that the oil runs off when the filter is removed, in order to ensure the complete changing of the oil at such infrequent intervals -as it may be necessary to clean the filter. The oil is forced to the three main bearings, and thence by the drilled crankshaft to the big-ends, the piston and gudgeon • pin relying upon splash lubrication.

The Albion-Murray governor mounted on the front end of the crankshaft is built into the crankcase, so that it is only accessiblewhen the engine is dismantled. The control gear to the throttle is likewiSe enclosed, so that it is absolutely impossible for the gessernor setting to be interfered with. Cooling is particularly effective, for whilst overcooling has been avoided, it has been proved on test impossible to make the water boil.

The gearbox is slung from a sub-frame, from which it can be dropped without touching the control mechanism, outside forks being employed without any pin joints. The gearbox is fitted with a full-size, inspection cover, a handy and good-sized drain tap and a special face plate that permits the mounting of a Kellog tyre pump if the chassis is to be pneumatic-tyred. The gearshafts are particularly heavy and tarried on large-diameter ball _bearings. Four speeds are provided, and the direct to is obtained by a dog clutch of the external and internal-tooth type. At the rear of the gearbox is fitted a largediameter loco-type brake of the usual Albion balanced type with hand-wheel adjustment. To the overhead-type worm-driven axle the drive is by a hollow shaft with a universal joint at each end. Both braking and torque loads are taken by the long 54-in, semi-elliptic springs.

The rear axle is of a patented triangular type. It is a one-piece drop-forging with centre flat ring and triangulated tubular extension, giving the utmost rigidity with the minimum weight. Aluminium is used for the overhead worm casing and also for the bottom cover, and the unsprung weight is thus reduced very much below the average for a vehicle of this type. There is a small inspection plate in the side of the worm housing and a well-placed oil filler extending to the rear of the axle.

Long and flexible springs front and rear give the suspension efficiency desirable in a passenger vehicle, and, while the rear springs are 54 ins, in length, those forward are no less than 42 ins. long.

The rear brakes are of the internal-expanding type, operated from the transverse brake shaft by -means of duplicate steel strips. The heavy-section side frames are eonnected by a tubular cross-member forwaid of the radiator, two arched channel members behind the dash, from which the gearbox sub-frame is carried, and three large tubular cross-members towards the rear. All through, the importance of easy adjustment and the highest degree of accessibility have been recognized. All the engine auxiliaries are well placed, and the complete engine can be lifted out without interfering with the dashboard, etc. The clutch can be taken out in 15 mins. and the gearboi can be dropped complete from the sub-frame. The live axle, , again, permits the lifting out of the worm drive and the withdrawal of the axle shafts without any dismantling. As regards perforinance, every effort has been made to provide an efficient and smooth-running engine and a quiet gearbox, whilst the desirability of a nice clutch take-up and easily changed gears on a publicservice vehicle has been recognized. The rear-axle

ratio for bus work is 61 to 1. The gear ratios are 4.22, 2.75 and 1.53 to 1 for the indirect gears, and 4.22 to 1 for the reverse. With full load the clutch

gives a perfectly smooth start on a gradient of 1 in 44 While the chassis described has been specially designed for bus work, another following the same

general lines is being standardized for motor coach bodies. The price Of the bus chassis on standard solidtyre equipment is, g555.