HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

620.—Adjusting Rear-wheel External Brakes on the 2-ton Burford.

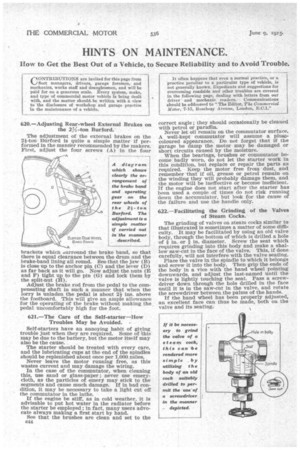

The adjustment of the external brakes on the 21-ton Burford is quite a simple matter if performed in the manner recommended by the makers. First, adjust the four screws (A) in the four brackets which .urround the brake band, so that there is equal clearance between the drum and the brake-band lining all round. See that the jaw (B) is close up to the anchor pin (C) and the lever (D) as far back as it will go. Now adjust the nuts (E and F) tight up to the pin (G) and lock them by the split-nut (H).

Adjust the brake rod from the pedal to the compensating shaft in such a manner that when the lorry is unladen the pedal is about 2f ins, above the footboard. This will give an ample allowance for the operating of the brake without making the pedal uncomfortably high for the foot.

621.—The Care of the Self-starter—How Troubles May be Avoided.

Self-starters have an annoying habit of giving trouble just when they are required. Some of this may be due to the battery, but the motor itself may also be the cause.

The starter should be treated with every care, and the lubricating cups at the end of the spindles should be replenished about once per 1,000 miles. Never leave the motor running free, as this wastes current and may damage the wiring. In the case of the commutator, when cleaning this, use sand or glass-paper ; never use emerycloth, as the particles of emery may stick to the segments and cause much damage. If in bad condition, it may be necessary to take a light cut off the commutator in the lathe.

If the engine be stiff, as in cold weather, it is advisable to put hot water in the radiator before the starter be employed ; in fact, many users advocate always making a first start by hand. See that the brushes are clean and set to the c44 correct angle ; they should occasionally be cleaned with petrol or paraffin. Never let oil remain on the commutator surface. A well-kept commutator will assume a plumcoloured appearance. Do not forget that if the garage be damp the motor may be damaged or short circuits caused by the moisture.

When the bearings, brushes or commutator become badly worn, do not let the starter work in this condition, but replace or repair the parts as required. Keep the motor free from dust, and remember that if oil, grease or petrol remain on the winding they will probably damage them, and the motor will be ineffective or become inefficient. If the engine does not start after the starter has been used a couple of times do not risk running down the accumulator, but look for the cause of the failure and use the handle only.

622.—Facilitating the Grinding of the Valves of Steam Cocks.

The grinding of valves on steam cocks similar to that illustrated is sometimes a matter of some difficulty. It may be facilitated by using an old valve body, through the bottom of which is drilled a hole of in. or in. diameter. Screw the seat which requires grinding into this body and make a shallow saw-cut in the face of the valve. This, if done carefully, will not interfere with the valve seating. Place the valve in the spindle to which it belongs and screw it into the body. Then grip the ends of the body in a vice with the hand wheel pointing downwards, and adjust the last-named until the valve is lightly touching the seat. Pass a screwdriver down through the hole drilled in the face until it is in the saw-cut in the valve, and rotate the screwdriver between the palms of the hands. If the hand Wheel has been properly adjusted, an excellent face can thus be made, both on the valve and its seating.