For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PBIZE OF TEN SHILLINGS is awarded each week to the sender of the best letter which we publish on this page ; all others are paid -for at the rate of a penny a line, with an allowance for photographs. All notes are edited before being published. Mention your employer's name, in confidence, as evidence of good faith. Address, D., M. and F., "The Commercial Motor," 7-13, Bosebery Avenue, London, E.G. 1. •

• f

Lamps Alight.

On Saturday, 11th January, light your lamps at 4.37 in London, 4.53 in Edinburgh, 4.23 in Newcastle, 4.38 in Liverpool, 4.39 in Birmingham, 4.47 in Bristol, and 5.23 in Dublin.

Replacing Worn Shackles and Shackle Pins.

The sender of the following communication has been awarded the 10s. prize this week.

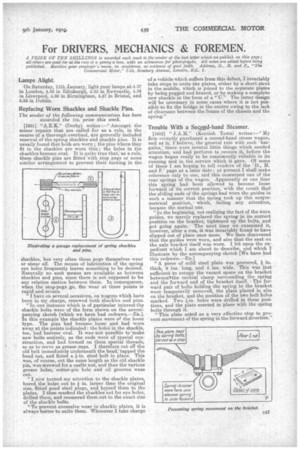

[1931] " A.E.K." (Derby) writes :—" Amongst the minor repairs that are called for as a rule, in the course of a thorough overhaul, are generally included renewal of the spring shackles and shackle pins. It is usually found that both are worn ; the pins where they fit in the shackles are worn thin the holes in the shackles become oval. It is quite time that, as a rule, these shackle pins are fitted with stop pegs or some similar arrangement to prevent their turning in the shackles, but very often these pegs themselves wear or shear off. The means of lubrication of the spring eye holes frequently leaves something to be desired. Naturally no such means are available as between shackles and pins, since there is not supposed to be any relative motion between them. In consequence, when the stop-pegs go, the wear at these points is

rapidrapid and severe. have on several occasions, on wagons which have been in my charge, renewed both shackles and pins. i

"In one nstance which is of particular interest the shackle bolts were of the form shown on the accompanying sketch [which we have had redrawn.—ED.]. In this example the shackle plates were of the loose type. The pins had become loose and had worn away at the points indicated : the holes in the shackle, too, had become oval. It was not possible to'make new bolts entirely, as the ends were of special construction, and had formed on them special threads, so as to serve as grease cups. I therefore cut off the old belt immediately underneath the head; tapped the head out, and fitted a i-in. steel bolt in place_ This was, of course, cut the same length as the old shackle pin, was screwed for a castle nut, and then the various grease holes, cotter-pin hole and oil grooves wee cut: "I now turned my attention to the shackle plates, bored the holes out to * in. larger than the original size, fitted good steel plugs, and brazed them to the plates. I then marked the shackles out for eye holes, drilled them, and reamered them out to the exact size of the shackle bolts.

"To prevent excessive wear in shackle plates, it is always better to unite them. Whenever I take charge

of a vehicle which suffers from this defect, I invariably take steps to unite the plates, either by a short strut in the middle, which is joined to the separate plates by being pegged and brazed, or by.making a. complete new shackle in the form of a "U." The latter design will be necessary in some cases where it is not possible to fix the bridge in the centre owing to the lack of clearance between the frame of the chassis and the spring."

Trouble With a Seggpd-hand Steamer.

[1932] " J.A.M." (Kentish Town) writes :—" My firm recently purchased a second-hand steam wagon, and as is, I' believe, the general rule with such 'bargains,' there were several little things which needed attention, and had perforce to receive it, before the wagon began really to be consistently reliable in its running and in the service which it gave. Of some of these I am hoping to tell readers of the D., M. and F.' page at a later date : at present I shall make reference only to one, and this concerned one of the rear springs of the wagon. Apparently at one time this spring had been allowed to become loose forward of its correct position, with the result that the sliding ends of the springs had worn the guides in such a manner that the spring took up this unsymmetrical position, which, failing any attention, became the normal one.

"In the beginning, not realizing the fact of the worn guides, we merely replaced the spring in its correct position on the bracket, tightened up the bolts, and got going again. The next time we examined it, however, after a run, it was invariably found to have slipped out of place once more. We then discovered that the guides were worn, and also that the seat on the axle bracket itself was worn. I hit upon the expedient which I am about to describe, and which I illustrate by the accompanying sketch [We have had this redrawn.—En.]

"A piece of mild steel plate was procured, in. thick, 6 ins, long, and 4 ins. wide. This was just sufficient to occupy the vacant space on the bracket betweentthe central clamp surrounding the spring and the forward end of the bracket itself. The forward pair of bolts holding the spring to the bracket were temporarily removed, the plate placed in situ on the bracket, and the position of the two bolt holes

marked. Two holes were drilled in these positions, and the plate erected in place with the spring bolts through it.

"This plate acted as a very effective stop to prevent movement of the spring in the forward-direction."