Bonderized Inside and Out

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

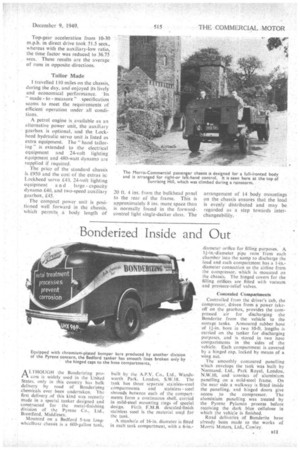

A LTHOUGH the Bonderizing pro cess is widely used in the United States, only in this country has bulk delivery by road of Bonderizing chemicals ever been undertaken. The first delivery of this kind was recently made in a special -tanker designed and constructed for the metal-finishing division of the Pyrene Co., Ltd., Brentford, Middlesex.

Mounted on a Bedford 5-ton longwheelbase chassis is a 600-gallon tank, built by the A.P.V. Co., Ltd., Wa.ndsworth Park. London, S.W.18. The tank has three separate stainless-steel compartments and stainless steel shrouds between each of the compartments form a continuous shell, carried in mild-steel mounting rings of special design. Firth F..141.B. descaled-finish stainless steel is the material used for the tank.

A manhole of 16-in, diameter is fitted in each tank compartment, with a 6-in. diameter orifice for filling purposes. A 11-in.-diameter pipe runs from each chamber into the sump to discharge the load and each compartment has a 1-in.diameter connection to the airline from the compressor, which is mounted on the chassis. The hinged covers for the filling orifices are fitted with vacuum and pressure-relief valves.

Concealed Compartments Controlled from the driver's cab, the compressor, driven from a power takeoff on the gearbox, provides the compressed air for discharging the Bonderite from the vehicle to the storage tanks. Armoured rubber hose of 11-in. bore in two 10-ft. lengths is carried on the tanker for discharging purposes, and is stored in two hose compartments in the sides of the vehicle. Each compartment is covered by a hinged cap. locked by means of a wing nut.

The smoothly contoured panelling which envelops the tank was built by Normand, Ltd., Park Royal, London, N.W.10, and consists of aluminium panelling on a mild-steel frame. On the near side. a walkway is fitted inside the panelling, and hinged doors give access to the compressor. The aluminium panelling was treated by the Pyrene Pylumin process before receiving the dark blue cellulose in which the vehicle is finished.

Road deliveries of Bonderite have already been made to the works of Morris Motors, Ltd., Cowley.