HINTS ON MAINTENANCE.

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Troubles.

CONTRIBUTIONS are invited for this page from fleet managers, drivers, garage foremen and mechanics, works staff and draughtsmen, and will be paid for on a generous scale. Every system, make, and type of commercial motor vehicle will be dealt with, and the matter should be written with a view to the disclosure of workshop and garage practice in the maintenance of a vehicle—practices which, whilst they may be quite normal, are peculiar to the particular vehicle and may not be generally known to those responsible for its running. Expedients and suggestions for overcoming roadside and other troubles are covered in the following page, headed "Roadside and Garage." Communications should be addressed to "The Editor, The Commercial Motor, 7-15, Rosebery Avenue, London, E.O. 1."

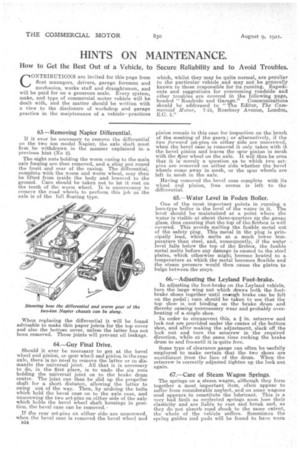

61—Removing Napier Differential.

If it ever be necessary to remove the differential on the two ton model Napier, the axle shaft must first be withdrawn in the manner explained in. a previous hint (No 2).

The eight nuts holding the worm casing to the main axle forging are then removed, and a sling put round the front and rear of the casing. The differential, complete with the worm and worm wheel, may then be lifted from inside the body and lowered to the ground. Care should be taken not to let it rest on the teeth of the worm wheel. It is inmecessary to remove the road wheels to perform this job as the axle is of the full floating type.

When replacing the differential it will be found advisable to make thin paper joints for the top cover and also the bottom . cover, unless the latter has not been removed. These joints will prevent oil leakage.

64.—Guy Final Drive.

Should it ever be necessary to get at the bevel wheel and pinion, or spur wheel and pinion inthe rear axle, there is no need to remove the latter or to dismantle the universal joint. All that it is necessary to do, in the first place, is to undo the six nuts holding the universal joint on to the brake drum centre. The joint can then be slid up the propeller shaft for a short distance, allowing the latter to swing out of the way. Then, by undoing the bolts which hold the bevel case on to the axle case, and unscrewing the two set-pins on either side of the axle which holds the bevel wheel shaft housings in position, the bevel case can be removed.

If the rear set-pins on either side are unscrewed, when the bevel case is removed the bevel wheel and s34

pinion remain in this case for inspection on the bench of the meshing of the gears; or alternatively, if the two forward 3et-pins on either side are unscrewed, when the bevel case is removed it only takes with it the bevel pinion and leaves the spur pinion in mesh with the Ipur wheel on the axle. It will thus be seen that it is merely a question as to which two setpins are removed on either side whether the bevel wheels come away in mesh, or the spur wheels are left in mesh in the axle.

Having removed the bevel case complete with its wheel and pinion, free access is left to the differential.

65.—Water Level in Foden Boiler.

One of the most important points in running a loco-type boiler is the level of the water in it. The level should be maintained at a point where -the water is visible at about three-quarters up the gauge glass, thus ensuring that the top of the firebox is well covered. This avoids melting the fusible . metal out of the safety plug. This metal in the plug is principally lead, which melts at a much lower temperature than steel, and, consequently, if the water level falls below the top of the firebox, the fusible metal melts before any damage is caused to the steel plates, which otherwise might become heated to a temperature at which the metal becomes flexible and the steam pressure would then cause the plates to bulge between the stays.

66.—Adjusting the Leyland Foot-brake.

In adjusting the foot-brake on the Leyland vehicle, turn the large wing nut which draws both the footbrake shoes together until enough brake can be felt on the pedal ; care should be taken to see that the -top shoe is not binding on the brake drum and thereby causing unnecessary wear and probably overheating of a single shoe.

In order to circumvent this, a in. setscrew and lock nut are provided under the centre of the bottom shoe, and after making the adjustment, slack off the lock nut and turn the setscrew in the required direction, while at the same time rocking the brake drum to and fro.until it is quite free.

Some type of clearance gauge can often be usefully employed to make certain that the two shoes are equidistant from the face of the drum. When the setscrew is correctly adjusted tighten up. the lock nut again.

67.—Care of Steam Wagon Springs.

The springs on a steam wagen, although they form together a. most important item, often appear to suffer frona considerable neglect, and on. some wagons mud appears to constitute the lubricant. This is a very bad fault as neglected springs soon lose their elasticity and are liable to rust and break and, as they do not absorb road shock to the same extent, the whole of . the vehicle suffers. Sometimes the spring guides and pads will be found to have worn considerably. Much wear could have been avoided by regular attention once or twice a week.

Each wagon should be jacked up at the rear peri9dloftily and the spring ends and guides thoroughly greased. It is a good practice to grease the whole spring outside, as even if the lubricant does not work between the leaves, it helps to keep away dirt and .moisture.

When overhauling a wagon the springs should either be taken -down altogether and the leaves scraped and thoroughly greased, or, if the springs are , left in position, the leaves should be forced 'apart with one of the special tools provided for the purpose, and grease insertedobetween them..

It is usually found that keeping the springs in good condition lessens the vibration very considerably and consequently reduces the repair bill ; it may also have considerable influence on the life of the tyres, and certainly adds -greatly to the comfort of the driver and his mate.