Judicious Pruning Saves Fuel

Page 32

Page 33

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

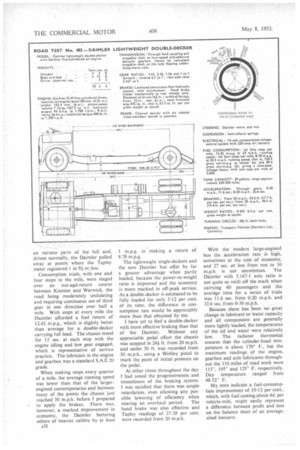

NOW that the Daimler lightweight double-decker has been in service and has proved its ability to maintain a normal schedule, operators are finding that it is a most economical vehicle to run. Nevertheless, my tests of the vehicle with the Gardner 5LW fivecylindered engine installed did not show the 2-mpg. improvement which is being obtained in service, because, unlike a service vehicle, it carried a load equal to 60 passengers throughout the day.

If the 12-15 years' potential life of a double-decker chassis is to be preserved, there can be no drastic Weight cuts in any component. Careful pruning is the only satisfactory way of reducing weight.

Apart from the use of a fivecylindered engine, there is no marked weight reduction in the engine or transmission, but 10 cwt. has been saved in the frame. tyres, springs, radiator, gearbox casing and methods of attaching units in the chassis. The engine of the test vehicle had the normal 94-b.h.p. rating at 1,700 r.p.m. and yielded 300 lb.-ft. torque at 1,300 r.p.m. In conjunction with the standard axle ratio of 5.166 to I, and full load, this engine setting is A30

practically the leanest possible for a bus that is required to perform like a heavier double-decker ,in flat or slightly undulating areas.

Where conditions are more ditfi cult. the operator has the choice of axle ratios of 5.8 and. 6.2 to 1, and a Gardner high-rated five-cylindered unit or a Daimler or Gardner sixcylindered engine. With the standard axle ratio and the engine governed to 1,700 r.p.m., the chassis has a maximum speed of 38 m.p.h. on 9.00 in. tyres.

A supply of cool air for combustion promotes economy and this condition is satisfied in the new model by conducting air from the canopy to the bulkhead, and then to the manifold by a flexible pipe. There is a 2i-in. air sPace in the bulkhead which acts as a cold chamber to increase the charge density. In the test chassis the induction system was naturally incomplete and sitting behind the bulkhead I was aware of a modulated induction roar. All induction noise is silenced when the body is fitted and air is drawn through the canopy.

Recent modifications to the engine idling speed and fluid coupling have improved fuel consumption when driving in traffic or stopping at points with a gear in engagement.. In effect. the engine idling speed has been reduced to 360 r.p.m. and the fluid coupling stalling speed raised from 450 r.p.m. to 605 r.p.m., thus causing less drag when stationary with a gear engaged, and improving acceleration.

To make engines easily interchangeable, the Metalastik rear mountings can he provided with arms of different lengths. The engine and gearbox mounting brackets are made of light alloy.

The traditional Daimler radiator is replaced by a conventional tube stack and straightsided top and bottom water tanks of anti-corrosive silicon allo3r, and screened by the front fairing. This fairing conforms to the present fashion of blending the front panel into the wings and body, but should styling change in the next 10-15 years, before the chassis has expended its useful life, it would be simple to modify the appearance.

A Daimler four-speed pre-selective gearbox with an Elektron casing is mounted separately amidships in the chassis with a steering-column gear lever and, in the test chassis, hydraulic actuation of the bus-bar. The Lockheed hydraulic pump is driven from the front of the gearbox to simplify the interchange of engines, and the gear-engaging control valve is arranged for equal pedal p;-essure in all gears.

ot a ble mechanical features include Clayton Dewandre strut-type brake-shoe operating gear providing constant-radius shoe thrust. R.P.

single-pull adjusters are mounted externally.

The location of the pull-off springs is another unusual development. They are placed at right angles to the line of cam thrust and act on the shoes through L-shaped rocking levers pivoted on the brake carrier.

Each spring is attached to a lug on one end of the brake carrier and to the short arm of the lever at the other, the long arm lying practically parallel to the axis of the spring. With this arrangement the pull-off effort remains constant and the mounting enables a nut adjuster to be used. Clayton Dewandre tripleservo braking forms an alternative.

Other departures from standard practice include spring brackets and spring chairs of light alloy and the replacement of the conventional tubular cross-members, which have heavy cast-steel end brackets, by light headed-up tubes flanged at the ends to form brackets. This applies to all members except the cross-tube at the front of the engine and that at the rear of the gearbox.

The frame width has been reduced by slightly over 21 in., which, in addition to saving weight, has enabled rear wheels with 6-in, rims to be used. The side members are inset in. in the region of the wheels. Weight reduction in the chassis, coupled with the use of an M.C.W. lightweight body, which now weighs 2 tons 1 cwt., has enabled lighter springs to be employed, and 9.0020-in. tyres are fitted all round, whereas formerly 11-in. tyres were fitted at the front.

The chassis was loaded to 10 tons running weight, the imposed weight of 5t tons representing a double-deck body 27 ft. long and 7 ft. 6 in. wide, and carrying 60 passengers. With 9-in. tyres at the front, the Daimler was light to steer in Coventry's traffic during an initial run to Sunrising Hill, which is about 25 miles from the works. The hydraulically operated gear-engaging pedal was liz.ht and the bus was easily con

trolled in congasted areas, where driving finesse is required for the comfort of passengers.

With the engine idling and a gear engaged I noticed that movement of the engine was being transmitted to the frame, but in neutral there was no perceptible oscillation on the chassis. There is to be a change in the composition of the engine suspension rubber further to isolate reaction of the unit.

Sunrising Hill, which is just over half a mile long and of 1 in 9 average gradient, has a steep section of 1 in 6i near the brow, where the Daimler came to a halt at the first attempt. On a repeat trial with the accelerator pedal partially depressed to gain further advantage from the injection-pump timing advance, the chassis just negotiated the hill.

Whe re such inclines are encountered daily, 1 would advise the use of a lower axle ratio. Starts from rem, again with full load, were made on various parts of the hill and, driven normally, the Daimler pulled away at points where the Tapley meter registered 1 in 9f or_less.

Consumption trials, with one and four stops to the mile, were staged over an out-aid-return course between Kineton and Warwick, the road being moderately undulating and requiring continuous use of third gear in one direction over half a mile. With stops at every mile the Daimler afforded a fuel return of 12.42 m.p.g., which is slightly better than average for a • double-decker carrying full load. The chassis stood for 15 sec. at each stop with the engine idling and low gear engaged, which is representative of service practice. The lubricant in the engine and gearbox was a standard S.A.E.20 grade.

When making stops every quarter of a mile, the average running speed was lower than that of the largerengined contemporaries and between many of the points the chassis just reached 30 m.p.h. before I prepared to apply the brakes. There was, however, a marked improvement in economy, the Daimler bettering others of heavier calibre by at least 1 m.p.g. in making a return of 8.78 m.p.g.

The lightweight single-deckers and the new Daimler bus offer by far a greater advantage when partly loaded, because the power-to-weight ratio is improved and the economy is more marked in off-peak service. As a double-decker is estimated to be fully loaded for only 5-12 per cent. of its time, the difference in consumption rate would be appreciably more than that obtained by me.

I have yet to find a double-decker with more effective braking than that of the Daimler. Without any appreciable pedal effort the chassis was stopped in 24f ft. from 20 m.p.h. and under 50 ft. was recorded from 30 m.p.h., using a Webley pistol to mark the point of initial pressure on the pedal.

At other times throughout the day I had noted the progressiveness and smoothness of the braking system. I was satisfied that there was ample retardation, even allowing any possible lowering of efficiency when nearing an overhaul period. The hand brake was also effective and Tapley readings of 27-28 per cent. were recorded from 20 m.p.h. With the modern large-engined bus the acceleration rate is high, sometimes at the cost of economy, and 27 sec. or less from rest to 30 m.p.h. is not uncommon. The Daimler with 5.167-1 axle ratio is not quite so swift off the mark when carrying 60 passengers and the averne time for a series of trials was 11.6 sec. from 0-20 m.p.h. and 32.6 sec. from 0-30 m.p.h.

Because there has been no great change in lubricant or water capacity and all components are generally more lightly loaded, the temperatures of the oil and water were relatively low. The radiator thermostat ensures that the cylinder-head temperature is about 170° F., but the maximum readings of the engine, gearbox and axle lubricants throughout the 110 miles of road work were 115°, 105° and 125° F. respectively. Day temperature ranged from 48-52° F.

My tests indicate a fuel-consumption improvement of 10-12 per cent.. which, with fuel costing about 4d. per vehicle-mile, might easily represent a difference between profit and loss on the balance sheet of' an average-. sized 'concern. ASUGGESTION that free competition might succeed where the Transport Act, 1947, had failed in co-ordinating road and rail transport was made, last weekend, by Mr. T. J. D. Morris, A.M.Inst.T.A., assistant transport manager of Chiswick Products, Ltd.

He was reading a paper on modern trends in handling freight traffic at the annual conference of the Institute of Traffic Administration, at South

sea. He stressed the importance of co-operation between users and carriers to make transport more efficient.

Mr. F. R. Moore, Minst.T.A., of West Bromwich Transport Department, dealt with passenger transport and methods of effecting economies. He spoke in favour of the use of crush-load single-deckers and of the judicious operation of one-man vehicles. He believed that the fiveday week would have to come to the transport industry.