D ESPITE continued recession and falling vehicle registration levels Britain's coach and bus markets ritinue to attract importers.

Page 31

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

One foreign name currently in the ws is that of Ikarus, the giant ingarian state bus producer that has its ;hts set on a share of the British bus d coach market and, through it, other irkets within the European Economic nnmunity.

It is well known that Ikarus has ncluded a deal to supply its latest 300 ries Blue Danube high-floor coach to itish dealer Kirkby Central. The deal ;o gives Kirkby the right to sell leftnd-drive versions into Europe. Kirkby has ordered 20 vehicles for delivery starting later this year. These coaches are all to be built on Volvo BlOM chassis.

The Hungarians are known to be hoping that Kirkby will take an option on a further 50 bodies. If this happens Ikarus will have become one of the top coach body importers to Britain within a relatively short time.

So just what is Ikarus? Some operators seem to think of the prospect of Hungarian bodies in the same way as they think of Eastern European cars; good value for money, but technically unsophisticated.

This is far from the truth for Ikarus has for long been to the forefront in Comecon bus production and was a pioneer in roll-over testing to ensure that its body structures are among the strongest available.

lkarus normally builds buses of over 14 tonnes, although it is likely that it would enter the mini/midi market if it identified an opening in the UK.

Current production exceeds 13,000 buses and coaches a year. It has exported buses and bus body kits to at at least 58 countries throughout the world, indeed 90 per cent of its production goes abroad. Often it has been in direct competition for business with British exporters, although it has an association with Bedford, supplying its bodies on TM chassis to customers in Nigeria.

IKARUS'S roots go back to the turn of the century although it took on its current form through the nationalisation of an established Hungarian coachbuilder in 1948. This company mainly made special vehicles such as fire engines and ambulances, but started bus production in Budapest that year.

It was in the Sixties that large-scale investment at Ikarus established the maker as the world's largest builder of full-size buses. Factory reconstruction projects started in 1964 and continued with the development of a number of plants including what is claimed to be the world's largest bus seat factory, turning out around 400,000 seats a year. At around that time the Raba Hungarian Railway Carriage and Machine Works in Gyor bought a licence to build MAN engines in Hungary.

0 N the model front, Ikarus developed the 200 type family of vehicles that forms the backbone of Ikarus production today. The range includes articulated buses, single-deck integral buses and high and normal-height coaches.

By 1982 10,000 200 Series Ikarus vehicles were being exported annually to other Comecon countries. An additional 3,000 went to capitalist countries in either built-up or kit form. Over 200 variants of the 200 series have been built.

The Ikarus plant in Budapest produces the largest vehicles, including artics, while a second plant at Szekesfehervar produces the smaller units. The two plants produce around 50 vehicles a day.

The company prides itself on its flexible approach to mass production. Most vehicles for its home market are powered by Raba MAN running units and are integrals using Hungarian Raba and Csepel components.

Other bodies have been fitted to a variety of chassis including Volvos and Scanias in Sweden, A via chassis from Czechoslovakia, Renault chassis for Algeria and on Berliet chassis built under licence in Poland.

American Ikarus buses have Cummins engines and Alison automatic transmissions.

Ikarus has also established body assembly plants in Iraq, Madagascar, China, Angola, Cuba and Libya.

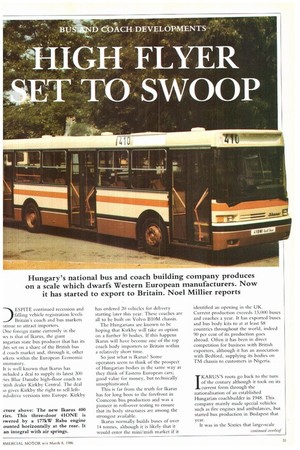

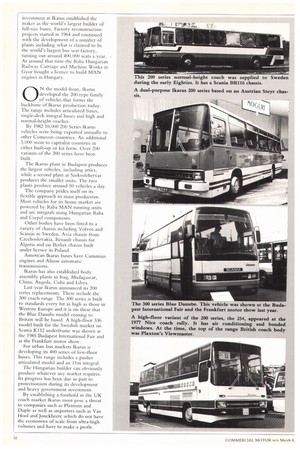

Last year Ikarus announced its 200 series replacements. These include the 300 coach range. The 300 series is built to standards every bit as high as those in Western Europe and it is on these that the Blue Danube model coining to Britain will be based. A high-floor 336 model built for the Swedish market on Scania K112 underframe was shown at the 1985 Budapest International Fair and at the Frankfurt motor show.

For urban bus markets Ikarus is developing its 400 series of low-floor buses. This range includes a pusher articulated model and an 11 in integral.

The Hungarian builder can obviously produce whatever any market requires. Its progress has been due in part to protectionism during its development and heavy government investment.

By establishing a foothold in the UK coach market Ikarus must pose a threat to companies such as Plaxtons and Duple as well as importers such as Van Hool and Jonckheere which do not have the economies of scale from ultra-high volumes and have to make a profit.