3L AND 5 TON MERCEDkS-DAIMLER CHASSIS,

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

Productions of One of the Best-known German Factories Embodying Many Features of Interest.

WE WERE RECENTLY afforded an opportunity of examining the latest Mercedes-Daimler chassis, which have recently been imported into this country by Mercedes Concessionnaires, Ltd., 21, Mercer Street, Long Acre, W.C. 2. It is not our policy to ignore what other countries, even if they have recently been our enemies, are producing as regards motor transport, and we cannot but acknowledge that these, the, latest products from one of the foremost factories in Germany, tertaiuly exemplify • Teuton thoroughness. They are •exceptionally solidly built, and certainly look capable of coping satisfactorily with the _ loads for which they are designed. It must be rememhei ed that Germaa transport during the war worked under great disadvantages, particularly as regards tyres; Most of the heavy lorrien ' were shod with iron, and the ensuing vibration neceasitatecrparticular care in the design and constructional methods. employed. A noticeable feature of the new chassis is the almost complete absence of rivets; wherever possible, bolts have been employed in lieu, and even in the building up of the frame these -bolts are provided with split-Pinned castle huts. Another feature; which was not unexpected, proved to be the almost complete absence of brass or copper flt, tinge, except for the smallest details, &itch as taps and connections; even the piping used for the circulation of oil and the supply of petrol is steel.

The 3i-ton model has bevel gear final drive, whilst the 5-tormer has an intermediate bevel gear and final drive by internal gears the construction being somewhat similar to that employed on many American chassis. Both chassis have pressed steel, channel-section frames, tapered to the clunah irons only, and inswept to a small extent from amidships to the dumb irons. In the smaller model the depth of frame is 5i ins. and in the larger 7 ins. Each side member of the latter is also strengthened at what is the weakest part of the frame in most chassis, i.e., in the neighbourhood of the driver's seat, by a channel steel liner of eomewhat thinner material to that employed for the members thetnse vcs.

'yo proceed with the description of the 3i-ton chassis, the engine has four cylinders of 108 non, bore by 150 nim. stroke, cast in pairs and developing 45 hp. at 850 to 900 r.p.m. Following the most recent practice, the valves are of the overhead type, operated by long tappetrode from a single camshaft contained in the cast-iron crankcase. The cylinder heads, with their valves, are-detachable. Each pair of valve-operating rocker arms is supported by a-single pillar provided with a spring-lid: lubricator. An enclosed -gear at the centre of the engine drives a shaft from which the magneto is driven at the rear end, and a fan-driving pulley at the front, a fabric belt being employed to drive the fan. Another pinion from the same set of gears drives the centrifugal water pump and the oil pump, the oil being forced to all parts of the engine. On the dashboard is an oil circulation indicator to ensure

that the oil pump is functioning eatisf.

torily. Three-point suspension is enplayed for the engine, in order to isolate it from the effects of frameflexion. The flat tube radiator is supported on bearings for the same reason.

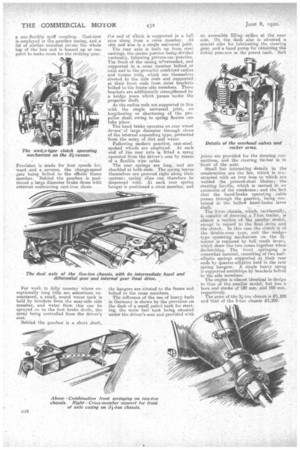

• An internal cone clutch, with a single leather-faced cone, is employed. The flywheel is spoked, and the spokes turned at an angle so that they act as fan blades. The spokes of the pressed steel clutch cone are also turned in a similar manner,

the two sets of spokes assisting the circulation of air through the radiator. The ckitch withdrawal mechanism, which is the subject of one of our illustrations, is of exceptionally neat design. 'Vertieallymoving wedges operate against two ehan'nelled rollers at, each side of the ballrace housings. Two thrust races are required as the wedging action is, of course, in both direction, although the movement is in one only.

Between the clutch and the gearbox le

a non-flexible muff coupling. Cast-iron is employed in the gearbox casing, and a lid of similar material covers the whole to of the box and is bossed up at one point to make room for the striking gear.

provision is made for four speeds forward and a reverse, the change-speed gate being belted to the offside frame member. Behind the gearbox is positioned a large diameter brake drum with external contracting cast-iron shoes.

For work, in hilly country' where exceptionally long hills are sometimes encountered, a small, round 'water tank is held by brackets from the near-side side member, and water from this can be sprayed on to the foot brake drucn, the spray being controlled from the driver's seat. .

Behind the gearbox is a short shaft, tire end of Which is supported in a ball .eace slung from a cross member. At this end also is a single universal joint. The ,rear axle is built up from steet castings the centre portion being-divided vertically, following private-car. practice. The front of the casing isoextendad, and supported in a cross member bolted at each end to the powerful combined radius and torque rods, which are themselves riveted to the axle ends and supported at their front ends from stout brackets bolted to the frame side members.. These brackets are additionally strengthened by a bridge piece which passes under the propeller shaft.

As the radius rods arn supported in line with the single universal joint, no lengthening or shortening Of the propeller shaft owing to spring flexion can take place.

The hand brake operates on roar wheel drums' of large diameter through shoes of the internal expanding type, protected from the entry of dirt and water.

Following modern practice, cast-steelspoked wheels are employed. At each end of the rear axle is fitted a. sprag operated from the driver's seat by means of a flexible wire cable.

The rear springs are long, and are shackled at both ends. The spring leaves themselves are grooved right along their centres; spring clips can therefore be dispensed with. At each rear spring -hanger is positioned a crass member, and

the hangers are riveted to the frame and bolted to the cross members.

The influence of the use of heavy fuels in Germany is shown by the provision on the dash of a small petrol tank for starting, the main fuel tank being situated under the driver's seat and provided with , an accessible 'filling orifice at the near side. On the dash also is situated a. special oiler for lubricating the steering gear, and a hand pump for obtaining the initial preKure in the petrol tank.. Ball joints are provided for the steering connections, and the steering tie-bar is in front of the axle.

Small but interesting details in the construction are the fan, which is constructed with an iron boss to which are welded the pressed-steel blades; the starting handle, which is carried in an extension of the crankcase; and the fact that the hand-brake operating cable passes through the gearbox, being, contained in the hohlo hand-brake lever shaft.

The 5-ton chassis, which, incidentally, is capable of drawing a 7-ton trailer, is almost a, replica of the smaller model, except in regard to the final drive and the clutch. In this cane the clutch is of the double-cone type, and the wedgetype operating mechanism on the 3twiner is replaced by 'bell crank levers, which draw the two cones together when declutching. The front springing is somewhat unusual, consisting of two halfelliptic springs supported at their rear ends by quarter-elliptics held in the rear spring hangers. A single heavy sprag is supported amidships by brackets bolted to the side members.

The engine is almost identical in design to that of the smaller model, but has a bore and stroke of 120 mm. and 160 mm. respectively. The price of the 31-ten chassis is £1,100 and that of the 5-ton chassis £1,200.