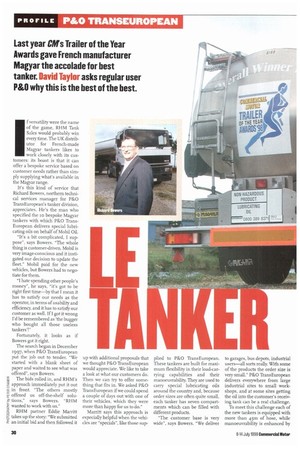

Last year Chfs Trailer of the Year Awards gave French manufacturer Magyar the accolade for best

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

tanker. David Taylor asks regular user P&O why this is the best of the best.

f versatility were the name of the game, RHM Tank Sales would probably win every time. The UK distributor for French-made Magyar tankers likes to work closely with its cus tomers: its boast is that it can offer a bespoke service based on

customer needs rather than sim ply supplying what's available in

the Magyar range.

It's this kind of service that Richard Bowers, northern technical services manager for P&O Trans European's tanker division, appreciates. He's the man who specified the io bespoke Magyar tankers with which P&O TransEuropean delivers special lubricating oils on behalf of Mobil Oil.

"It's a bit complicated, I suppose", says Bowers. "The whole thing is customer-driven. Mobil is very image-conscious and it instigated our decision to update the fleet." Mobil paid for the new vehicles, but Bowers had to negotiate for them.

"I hate spending other people's money", he says, "it's got to be right first time—by that I mean it has to satisfy our needs as the operator, in terms of usability and efficiency, and it has to satisfy our customer as well. If I got it wrong I'd be remembered as 'the bugger who bought all those useless tankers'!"

Fortunately, it looks as if Bowers got it right.

The search began in December 1997, when P&O Trans European put the job out to tender. "We started with a blank sheet of paper and waited to see what was offered", says Bowers.

g The bids rolled in, and RHM's

g approach immediately put it out .

5 in front. "The others mostly

offered us off-the-shelf soluN tions," says Bowers. "11.FIM wanted to work with us."

RHM partner Eddie Marritt g takes up the story: "We submitted k an initial bid and then followed it

up with additional proposals that we thought P&O TransEuropean would appreciate. We like to take a look at what our customers do. Then we can try to offer something that fits in. We asked P&O TransEuropean if we could spend a couple of days out with one of their vehicles, which they were more than happy for us to do?

Marritt says this approach is especially helpful when the vehicles are "specials", like those sup plied to P8E0 TransEuropean. These tankers are built for maximum flexibility in their load-carrying capabilities and their manoeuvrability. They are used to carry special lubricating oils around the country and, because order sizes are often quite small, each tanker has seven compartments which can be filled with different products.

"The customer base is very wide", says Bowers. "We deliver to garages, bus depots, industrial

users all sorts really. With some of the products the order size is very small." MO Trans European delivers everywhere from large industrial sites to small workshops, and at some sites getting the oil into the customer's receiving tank can be a real challenge.

To meet this challenge each of the new tankers is equipped with more than 45m of hose, while manoeuvrability is enhanced by Hosta positive steering on the rear Mentor axle. "These are urban trailers, designed to get into tight spots. They've got a turning circle as good as many four-wheeled rigids," says Bowers.

The long delivery hose means the tanker driver can station himself at the tanker or at the customers' receiving tank. Drivers can't be in two places at once, so one innovation on the new trailers is a radio remote control which allows the driver to control the tanker's pump.

"The driver has to be in a position to prevent over-filling the customer's receiving tank and must be able to respond as quickly as possible to spillages. This is where the remote control comes into play", says Bowers. "This is particularly important where you're operating in a public environment."

The remote control is a proprietary system adapted by Magyar, says Marritt. "In France it is a well-established feature," he adds. "Here in the UK these are the first tankers we've supplied with the remote control".

Driver's job

Everything has been done to make the driver's job as straightforward as possible. Although each tank has seven compartments, there are only two meters. "The driver just selects the pump he wants to use, connects the hose and off he goes," says Bowers. The system includes a blow-down which ensures that as little oil as possible remains in the hose between deliveries, to guard against cross-contamination. Another useful feature is the automatic lifting front axle. "When there's nine tonnes or less in the tanker the forward axle lifts automatically—the driver doesn't have to do a thing," says Bowers.

It seems paradoxical that to cut costs you often have to spend a bit of money, but this is what lies behind P&O TransEuropean's fleet revamp. Until the delivery of its new Magyar trailers it had a fleet of ex-BP and ex-Mobil rigid tankers (BP and Mobil are partners in the lube oil operation).

Moving from these three and four-axle rigids to artics has lent a new flexibility to the fleet. The tractors can be replaced on a more frequent cycle than the trailers, which generally have a longer lifespan, and the tractor fleet can be kept "lean" to keep overheads low. "They service many other trailers besides our tankers," Marritt explains.

The two-axle Magyar trailers, which have a capacity of 25,00 o litres, are designed to run at 38 tonnes GVW, but P&O TransEuropean operates them at 32. "The order size means we seldom get a full load," says Bowers.

This doesn't mean P&O TransEuropean hasn't got much work on. RHM is already working on the next batch of trailers for delivery later this summer.

This order is for five nine-compartment, single-axle, 26-tonne tankers to replace 17-tonne twoaxle rigids. They will be tailored to those small-order, multi-delivery jobs, and useage will be high, says Marritt. "It's an evolutionary process", he concludes. He's obviously been studying his customer's business again.