MAKING BEST USE OF THE FORD.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, Which will Appeal to the Owner, Driver and Repairer.

TN THIS series of hints concernXing the Ford light chassis and ton truck, we endeavour to deal with the subject from every viewpoint, so that the advice will appeal to the owner, driver, maintenance engineer or mechanic.

We shall welcome for inclusion among the hints those which 'have proved of value to individual users, and will make suitable remuneration for any which are published.

366.—Retaining the Efficiency of Dry-track Timers.

Certain timers, such as the Runbaken, are intended to run dry, andtrouble may be caused if oil works through on to the timer face, as a muddy ewarf is formed which interferes with the efficient working, for it clogs in the wire brush and may cause burning of the track due to imperfect contact.

A great deal of this trouble can be obviated by maintaining in good condition the felt lining situated at the back. To get at this lining it is necessary to remove the bush assembly from the timer shaft, and also the sheet-metal cover, when the felt will be disclosed in the recess. If the felt has become bard it should be renewed.

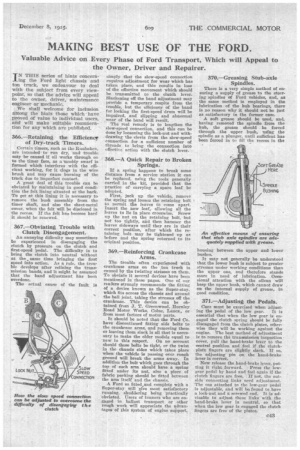

367.—Obviating Trouble with Clutch Disengagement.

An annoying difficulty may sometimes be experienced in disengaging the clutch by pressure on the clutch and first-speed pedal. The difficulty is to bring the clutch into neutral without at the_ same time bringing the first speed into action. As a rule, the trouble develops after relining the transmission bands, and it might be assumed that the band adjustment has been overdone.

The actual cause of the fault is simply that the slow-speed connection requires adjustment for wear which has taken place, and this results in loss of the effective movement which should be transmitted to the clutch lever. Slackening off the band adjustment may provide a temporary respite from the trouble, but the efficiency of the band for locking the first-speed drum will be impaired, and slipping and abnormal wear of the band will result.

The real remedy is to lengthen the slow-speed connection, and this can be done by loosening the lock-nut and withdrawing the devis from the slow-speed connection for a sufficient number of threads to bring the connection into effective action with the clutch lever.

368.—A Quick Repair to Broken Springs.

If a spring happens to break some distance from a service station it can be replaced. using the tools generally carried in the kit, provided that the practice of carrying a spare leaf be adopted.

First, jack up the vehicle, remove the spring and loosen the retaining bolt to permit the leaves to come apart. Insert the new leaf, allowing all the leaves to lie in place crosswise. Screw up the nut on the retaining bolt, but not too tightly, arid then hammer the leaves sideways until they are in their correct position, after which the retaining bolt may be tightened up as before and the spring returned to its original position.

369.—Reinforcing Crankcase Arms.

The trouble often experienced with crankcase arms on the ton truck is caused by the twisting stresses on them. To obviate it several devices have been mentioned in these pages. One of oar readers strongly recommends the fitting of a device known as the Super-stay, which fits across the chassis and around the ball joint, taking the stresses off the crankcase. This device can be obtained from J. T. Greenwood, Burnley Road Motor Works, Caine, Lancs., or from most factors of motor parts.

It should be noted that the Ford Co. have discontinued fitting side bolts to the crankcase arms, and removing these or leaving them slack is all that is necessary to make the older models equal to new in this respect. On no account should these bolts be tight, or the twist in the chassis sides which takes place when the vehicle is passing over rough ground will break the arena away. In addition the boll which goes through the top of each arm should have a spring fitted under its nut, also a piece of fabric packing should be fitted between the arm itself and the chassis.

A Ford so fitted and, complete with a Super-stay will give most satisfactory running, shuddering being practically -obviated. Users of tonners who are engaged in ballast transport or other rongh work will appreciate the advantages of this system of engine support. 370.—Greasing Stub-axle Spindles.

There is a very simple method of ensuring a supply of grease to the steering spindles of Ford vehicles, and, as the same method is employed in the lubrication of the hub bearings, there is no reason why it should not he just as satisfactory in the former case.

A soft grease should be used, and, having removed the spindle front the hub, the grease should be forced through the upper bush, using the spindle as a plunger, until suffideut has been forced in to fill the recess in the

housing between the upper and lower bushes.

It may not generally be understood that the lower bush is subject to greater stresses under working conditions than the upper one, and therefore stands more in need of lubrication. Occasional attention with the oilcan will keep the upper bush, which cannot draw on the internal supply of grease, in good condition.

371.—Adjusting the Pedals.

Care must be exercised when adjusting the pedal of the low gear. It is essential that when the low gear is engaged the clutch spring should be fully disengaged from the clutch plates, otherwise they will be working against the engine. The best method of adjustment is to remove the transmission inspection cover, pull the hand-brake lever to the central position and feel if the clutchplate fingers are slightly slack. If so, the adjusting pin on the hand-brake lever is correct.

Now release the hand-brake lever, putting it right forward. Press the lowgear pedal by hand and feel again if the clntch fingers are free. If not, the outside connecting links need adjustment. The one attached to the low-gear pedal is adjustable, and will he found to have a lock-nut and a screwed end. It is advisable to adjust these links with the hand-brake lever in neutral, so that when the low gear is engaged the clutch fingers are free of the plates.